New baby = handfull - Congratulations!

My kids legitimized my childish behavior…

I plan on using this one and the future ones as cover and scape goats.

Thanks:)

Hah! Love it!

If I upgrade to another 3d printer it will be a delta style, possibly one of the SeeMeCNC models, I think. I currently have one of the Bukito printers, not bad, but a little small.

I think I want to buy a plasma cutter next though.

My son researched plasma cutters for his CNC Gotorch.

He settled on Hypertherm powermax 45. Slick little machine! Half the size of my 20 year old one and cuts twice the thickness at half inch, with a15 foot torch lead, Around $1500.

Hypertherm units are nice, we have one at work, but, I don’t remember the model # I’m not initially planning to CNC it, but I thought this Multiplaz looked like a pretty good value, about $2000. I find it interesting that will cut ceramics and weld as well.

Wow!

Very cool. Impressive duty cycle on that thing - 100% 24/7!

Cutting non conductive material is serious innovation.

Interesting, water is a mortal enemy of regular plasma cutters. Alcohol and water surprises me just because most molten metal has an affinity for oxygen, usually with detrimental consequences.

That looks like an incredible tool! I haven’t had access to a plasma cutter since college, but I loved working with one then. This looks like it could be even better, what with not having to be running a compressor the entire time you are cutting. Looking at the photos on their site, I’m a little unsure where the water or water-alcohol mixture is actually stored… is it in the unit?

Gah, I want ALL the tools.

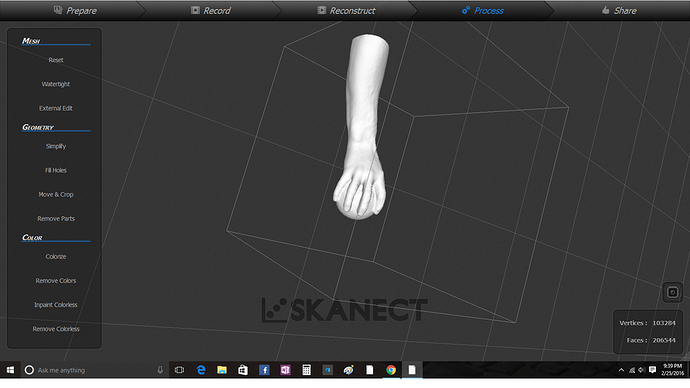

One companion tool for the GF that I have been experimenting with while I wait is the Structure Sensor. It’s a small scanner that connects to your Ipad and allows you to scan objects in 3D. I think it goes with the GlowForge nicely as all those cardboard models you create can start from a single scan right at home. after scanning and printing a few of my buddies, I thought i would experiment with a few other ideas. I had my wife scan my arm while holding a bouncy ball thinking i could turn that scan into a claw foot table leg of some type. (The wife thinks it a bit creepy, but trying it out for the sake of experimentation)

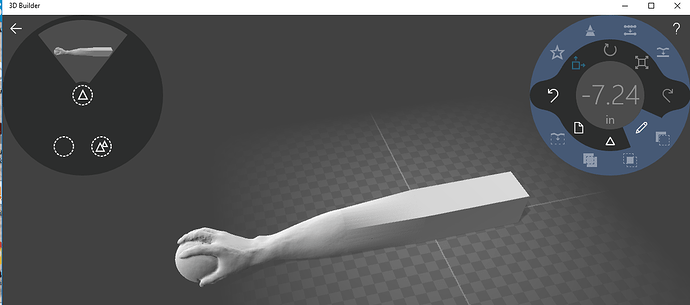

above you can see the initial scan data in Skanect (which has met all my expectations and more for being new technology) Below, I lofted the arm to transition to a square table leg.

Since I cannot afford a fancy 5 axis milling machine capable of producing wooden legs this big, I printed and assembled the plastic print and loaded it into a router carving duplicator.

Below you can see the hand beginning to reveal itself from the test piece of pine blank that I had glued up. The next leg, I think i will use less wood as it sure is a lot of meat for the router to chew through. perhaps the GlowForge will assist with producing a scaled up 123D make lamenated blank and then i only have to route the finishing details to smooth with little waste.

Man that looks sweet! Did you build the tracing router yourself? If so, im impressed!

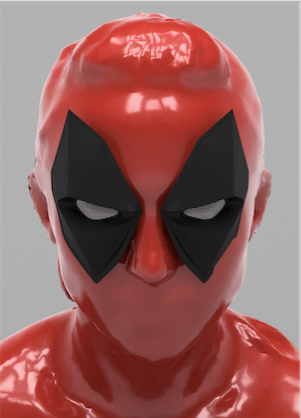

I also have a structure sensor, theyre so much fun! I use it to design costumes for myself and my friends.

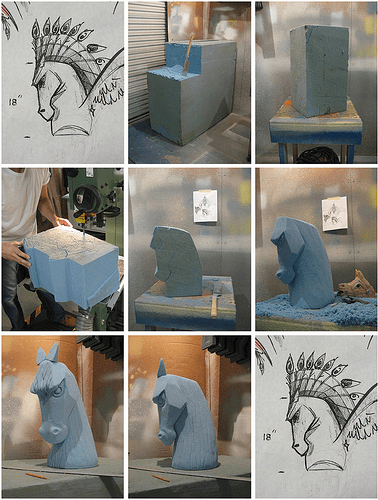

For the material clearing, have you considered going a little oldschool and using a bandsaw/reciprocating saw/jigsaw to remove a good bit of that stock before fine tuning it with the router? Similar to foam sculpture techniques:

then use the tracing router to cut in the fine detail

Wow! that is another cool application for the sensor. Great work! I actually purchased the tracing router assembly and just mounted to some plywood. The bandsaw idea is a great idea. I think I could just print the 123D pdfs on paper over the wood, bandsaw, then glue or possibly mark out some areas where less material is needed and add blocks only where needed to save time. That foam horse is some serious art by the way!

Wow, are you kidding me?! This is AWESOME.

People in this forum are so talented.

I’ve been reproducing my product line in Illustrator, so I can be ready when my baby comes. Also, because a friend knows someone in Philadelphia with a beta GF so I’m going to test it out. Can’t wait to cut a few days of leather in a few minutes. So disappointed about the wait but still can’t wait to get it.

And I have a bridge in New York…

pics or it didnt happen

Still working on Illustrator files. After I finish I’ll contact my friend and set it up. Give it time baby

Geesh, so much pessimism.

Had been cutting brush all morning and fell asleep for 30 minutes when I came back in. Hadn’t woke up enough to recognize the tongue in cheek humor. Knew it seconds after I hit post. Oops.

As far as is company acknowledged, there is only one public beta.

That’s not to say there aren’t private beta’s out there, just that none we are aware of. If there is, then you just let his cat out of the bag

Wow, loving the superhero and horse cuts!

This was actually what I was going to buy, that is, before I found out about the GF. Yeah, it seemed counter to experience for me as well, but the thought of having all that capability in one small package is very enticing.

Now, I have to start saving again. I had both of my vehicles die in the last couple months, and had to drop 3k on another. I’m back at square zero, but might be able to swing it by the end of June.