James… yes, I agreed to beta. That is not my issue here. My issue is that I see very little improvements. Having worked in the tech industry and also running several companies and or divisions. I do not see much improvement/progress? That is what I’m bitching about. But hey… Its in the hopper cause Dan says so. So everything will be A okay… Unless something happens soon I’m sure that you and many other followers will be thinking the same.

I used to think they were working on this behind the scenes and would suddenly roll it out. Now after years of no progress I am starting to think they are waiting to recruit a computer vision specialist that they have been trying to recruit for a long time and not actually working on it all. Perhaps they had one that left and that explains how they got to where they are now a long time ago and nothing has improved since. According to the waybackmachine they were recruiting for that job in 2015!

Hi Eric,

In the passthrough demo that @markwal linked to, I did have problems with the top curve popping up due to the weight of the cardboard in front of the machine. Fortunately, it cut the inner curve OK even though it was way off the crumb tray at that point.

However, I didn’t have any trouble getting it through the rear passthrough slot. And, after the first cut, I placed additional magnets on the material to hold it from rising up again. I don’t think you’ll need to leave bridges holding your pieces to the background for that.

Your ship model looks great. I hope you are able to master the indexing needed to cut the long pieces accurately.

This should be worrying people.

I thought this for a while as well. But then they make weird changes behind the scenes that seem to break stuff, then fix it. What the heck is that? If you were sandbagging all your changes to roll them into one big WAHOO!!! update, why would you be making this silly changes in the production system?

My hope was rekindled when they announced the date for the price increase. Could that be a release date for a much needed boost to the quality of the service? I don’t have my hopes up.

Seriously, the code base that the current production firmware is built from (mostly unattributed open source code, mind you - so much for @dan being all loving and respectful to creators) is mostly from 2014-2015.

They didn’t bother to refresh any of it in the build they just did in October. What kind of developers are these?

It’s downright puzzling.

I think mostly ones that have not been recruited yet.

Well, not to dog on anyone - but there are some serious rookie mistakes in there.

For instance, Development 101: Do NOT leave hardcoded credentials in your production releases.

Sigh.

I think that Glowforge focused their resources on getting the hardware as good as possible as their first priority. They got the software to MVP (Minimum Viable Product in start-up speak) so that even though the software doesn’t do all we (or they) want it to, it does make the machine very usable–even though we sometimes have to invent workarounds for the things they have promised to make it do.

They can update the software–both the cloud software that does the motion planning and user interface, and the firmware that lives on the machine–as frequently as makes sense, and they can continue to make the experience better.

What they cannot do is fix a fundamental problem with the hardware. Rushing the hardware out the door with significant flaws that can never be fixed in software would kill the company and we users who received such flawed units would be left high and dry.

So I think this set of priorities was the correct way to approach getting these machines shipped. And there was significant software work involved getting the thing manufactured and properly tested (and enough information recorded during calibration to make future alignment improvements possible).

Having worked in startup companies before, it is not uncommon to have open position categories listed for the kinds of skillsets they are looking for. It does not mean that they have just one opening in computer vision. It also doesn’t mean that they don’t have anyone with a computer vision background.

It’s much more likely that the person or people they do have with that skillset also has other relevant skillsets and that they were working on higher priority work.

Computer vision is an extremely important skillset for many of the features they need to work on. They will probably list that opening until they no longer need any more software engineers at all. If they found a Computer vision goddess who had no other relevant skills, they’d probably hire her specifically for the CV work, and someone who was stronger in other areas would focus on those other areas. More likely, they’ll find people with good skills in multiple areas and those people will work on a variety of tasks.

They seem to have finally gotten over the hump on manufacturing this device. Now we all want the software to be at the same polished level. It will get there. Its just not had the love of proper resources until now.

This may or may not be a bad thing. Any time you pull upstream changes you have a chance of breaking the rest of the system. [edited to add:] Also, the code I think you are referring to is the code that runs locally on the Glowforge. It seems that most of the activity towards adding the features we’re missing would be on the server side.

Agreed, Sigh.

Agreed. The bigger issue is that the current code base has a slew of known vulnerabilities. They should be keeping up with advances made in the code base that they built their foundation on. That way, any changes will have minor impact, likely require little change to their code that relies on it, and is much easier to test.

Indeed. We don’t know what’s going on with the server side.

I agree. Though, it seems that the bulk of the hardware has been stable for some time with little change. This would leave them with plenty of ability to work diligently on developing the software features.

I sincerely hope, for those that are going to be dependent on the cloud software, that there has been lots done that we haven’t seen, and that a YUGE release is coming.

I’m optimistic @jason.fuller0 but would like to know more about the head camera and their calibration procedures, including the camera specs, interior orientation process, people doing the work and bundle adjustment / “flight pattern” over the GF bed. If you have ever calibrated a camera, you probably know that they have to be redone periodically and if they get out of calibration, can we input data and have our specific camera recalibrated thru the cloud.

Wish they would share more info, they could get good feed back from the many talented people in this Forum. I hope they are not reinventing the wheel but consulting the many photogrammetric companies that have had soft copy photogrammemtric systems in operation for decades that could assist them in solving this fairly quickly, assuming GF made good decisions about the camera hardware upfront.

Having read the forum for years now, there seems to be an incredible amount of talent here that knows how to do the various and sundry parts of this hardware, this software, the sales and manufacture and packaging and shipping logistics far better than GF – how to avoid the “rookie” mistakes, how to provide a better and more efficient and more foolproof software package and hardware unit.

I’ve read how many folks here have solved over and over again the supposed deficiencies in all those areas, and more

I’m actually kind of amazed that many of you haven’t gone ahead and gotten together and formed your own company to make a laser with all these things addressed…

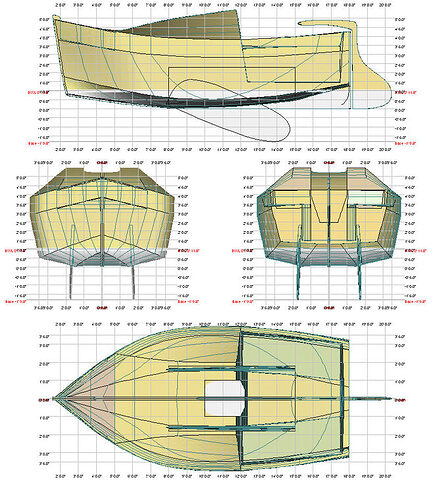

By the OP those folks who want to make boats and planes, And as it is ![]() that means a bunch of hard chine curves and calculating what they would be when flat is a bit tricky. A while back I discovered this it is created for designing boats but any bilaterally symmetrical idea can be designed, and there is a rendered version of all the planes laid out flat. It might take something like Inkscape for conversion therapy to make them work for cutting but quite complex designs can be built.

that means a bunch of hard chine curves and calculating what they would be when flat is a bit tricky. A while back I discovered this it is created for designing boats but any bilaterally symmetrical idea can be designed, and there is a rendered version of all the planes laid out flat. It might take something like Inkscape for conversion therapy to make them work for cutting but quite complex designs can be built. ![]() is a bit small for full size as I would like, but could be great as models. This is one of many sailboats I did

is a bit small for full size as I would like, but could be great as models. This is one of many sailboats I did

…and so, we will soon see a new laser startup from the folks here?

Wouldn’t you prefer to see those folks improve the one you already own?

Or would that not feed into the derisive attitude that I’m picking up?

Attack the issues, not the people bringing attention to them, please.

Thank you for the advice on what I should and should not communicate.

Personally, I’m impressed with the folks who are actually already making this device, doing the hard work and producing it… Its the doing i like – the sidelines talking (“Monday Morning Quarterbacking”), not so much.

But I will definitely keep your comment about my posting etiquette in mind.

Yes, the last several months others and I have spent diligently reverse engineering this device so we could make some strides to improve upon it was certainly some useless sideline action.

Thank you for reminding me about just the sort of people that would benefit from it, and opening my eyes to error of my ways.

I will definitely keep your comments in mind as I decide on somewhere else to donate my time and resources.

I think there’s a distinction between you & your helpers and the ones who just talk about how they could make things better/faster. At least you’re doing something about it. In fact, doing it now and invalidating the warranty is pretty much the definition of put your money where your mouth is. ![]()

That’s how the Cohesion Board and Laserweb projects took off.

Very cool. I’ve always been interested in the sailboats plans and their laserability. Good to know there’s someone in the Forums who is leading the charge.