Good morning @Rita and @Vee - thank you both for your patience. I am now back among the living. Finally.

I did three tests this morning. Short story, my GF still isn’t working properly.

I turned on the GF for the first time in approx. 2 weeks. No issues noted during start-up and cal.

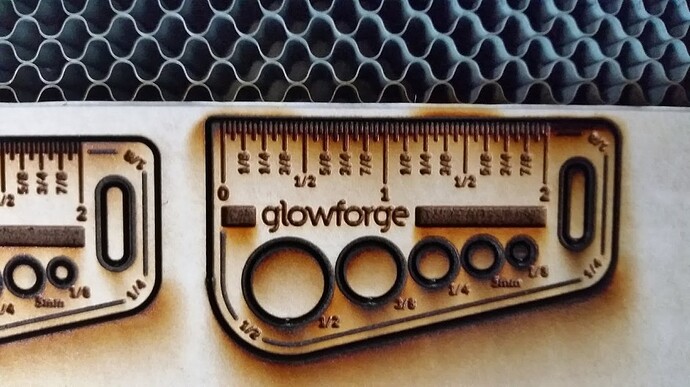

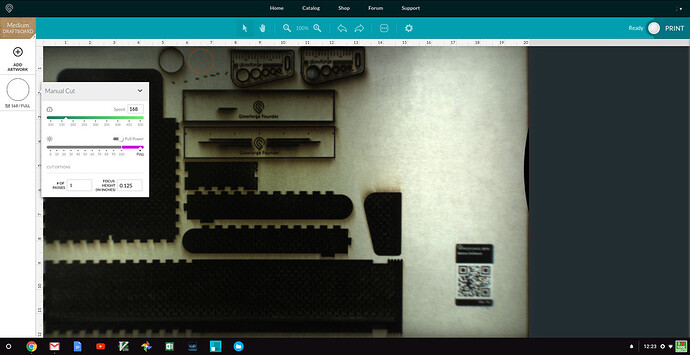

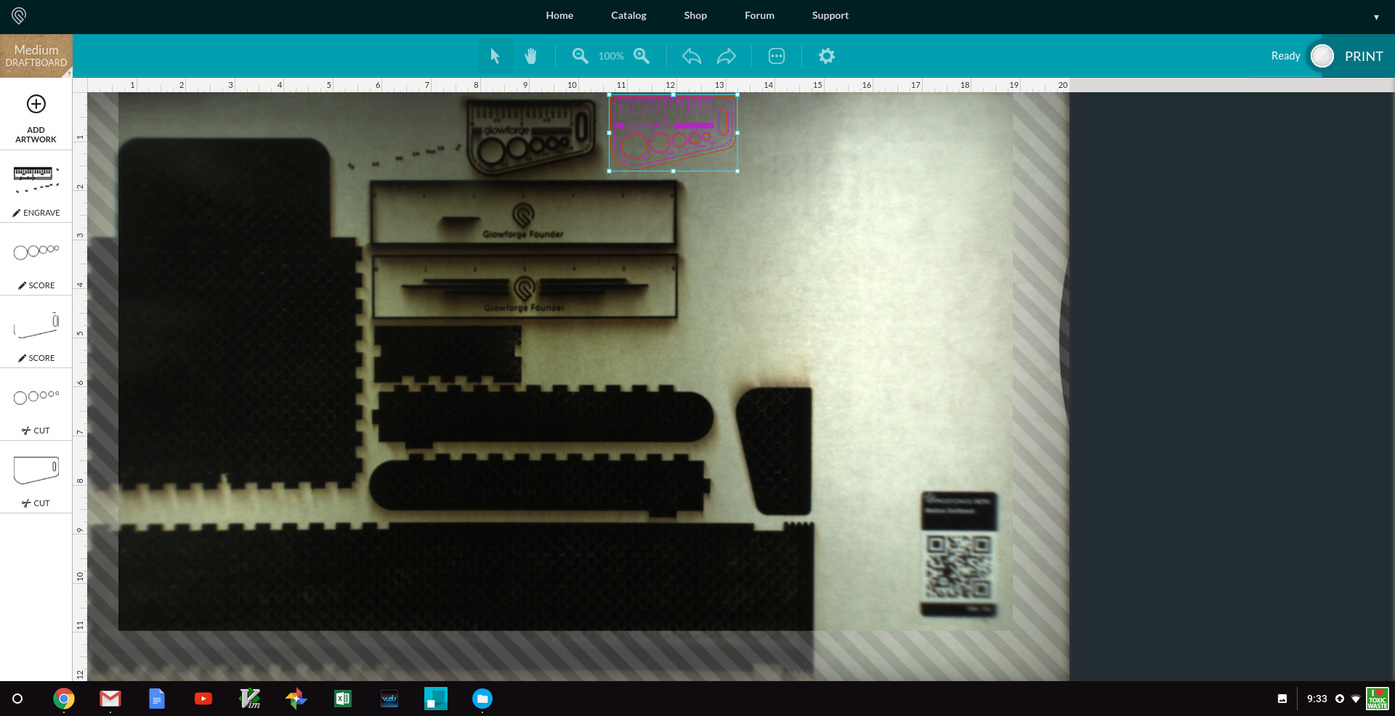

File used for testing: Gift of Good Measure on Medium Draftboard

Test Run 1:

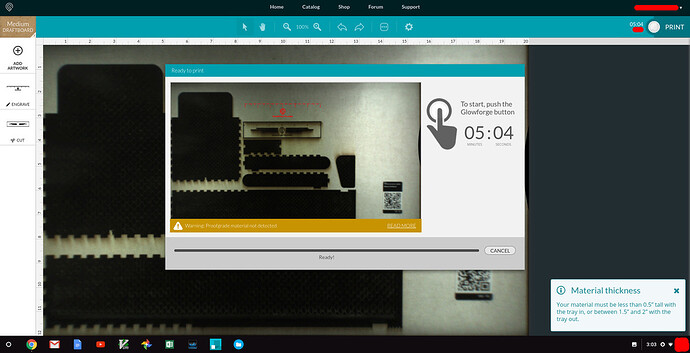

Loaded artwork and positioned in GFUI.

Selected material (medium draftboard - this was after a false start choosing Thick Maple which apparently was next to my target the firs time. I aborted that print when I noticed the anomaly).

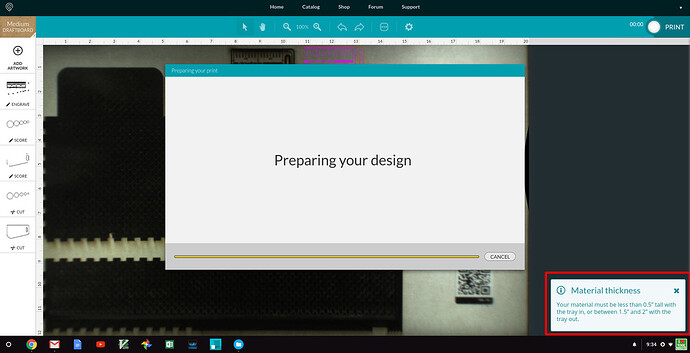

Selected the Print Button - Scanning - Error Message for Material Thickness

Time = 9:06 AM EST 2/12/2018

Proceeded (with low expectations due to thickness error message)

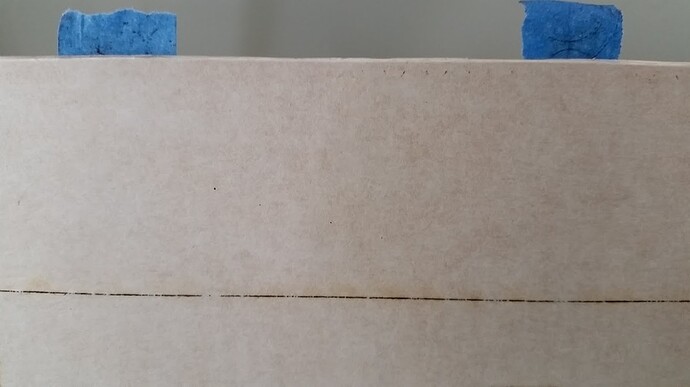

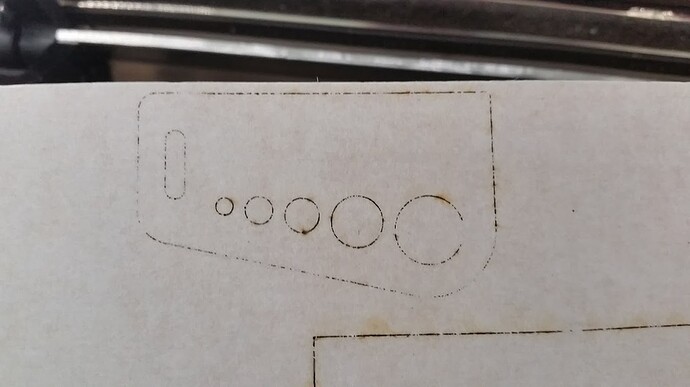

Result - did not cut through

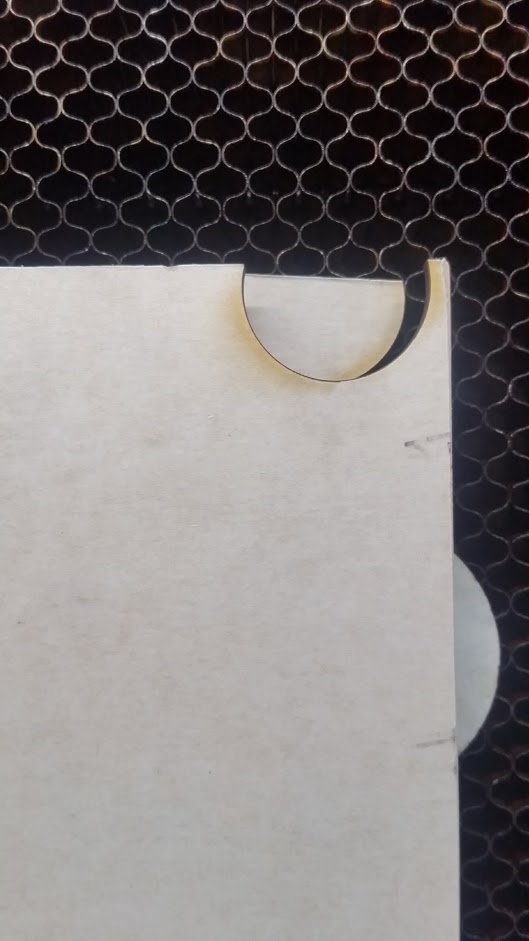

Backside - no penetration (blue tape marks bounds from front side, see above photo). The line is from the failed ruler prints 2 weeks ago)

Recycled machine in case there was something queued to download. Nope

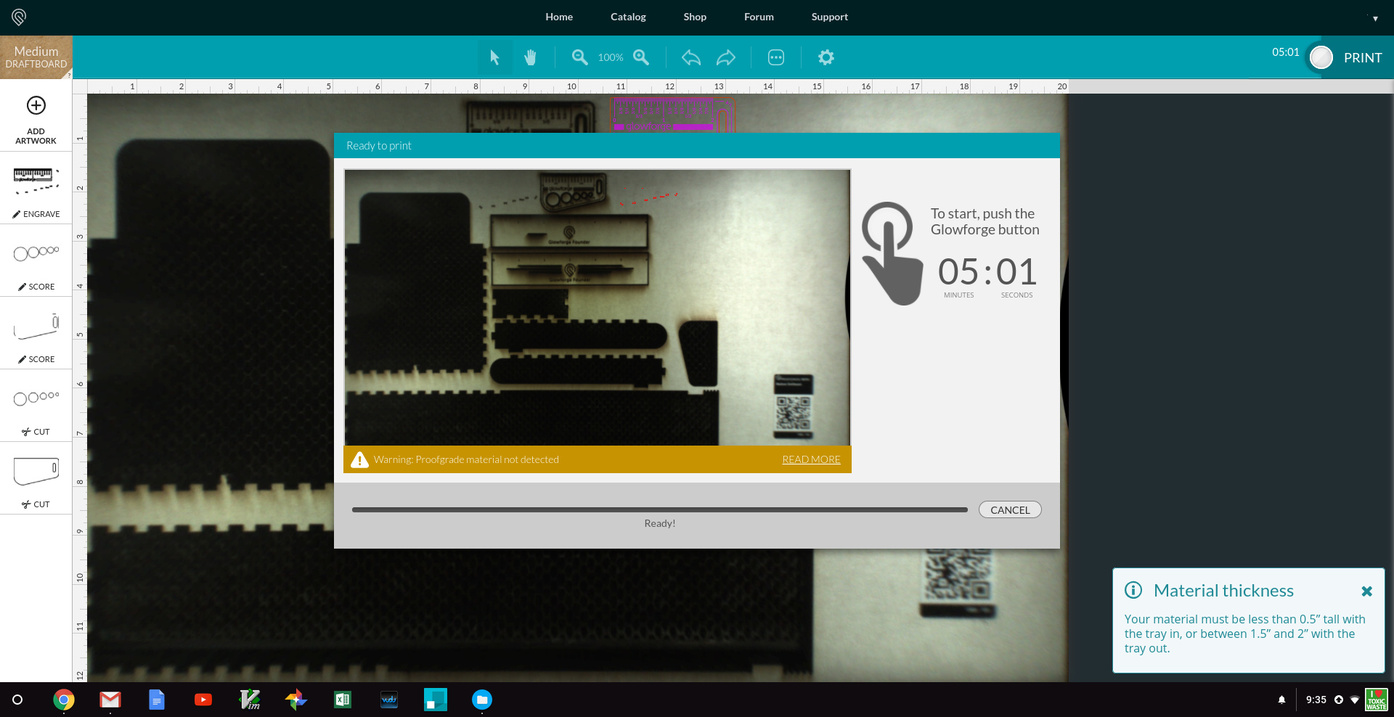

Test Run 2:

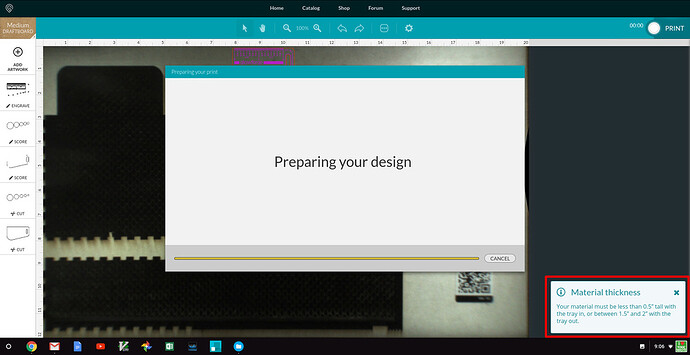

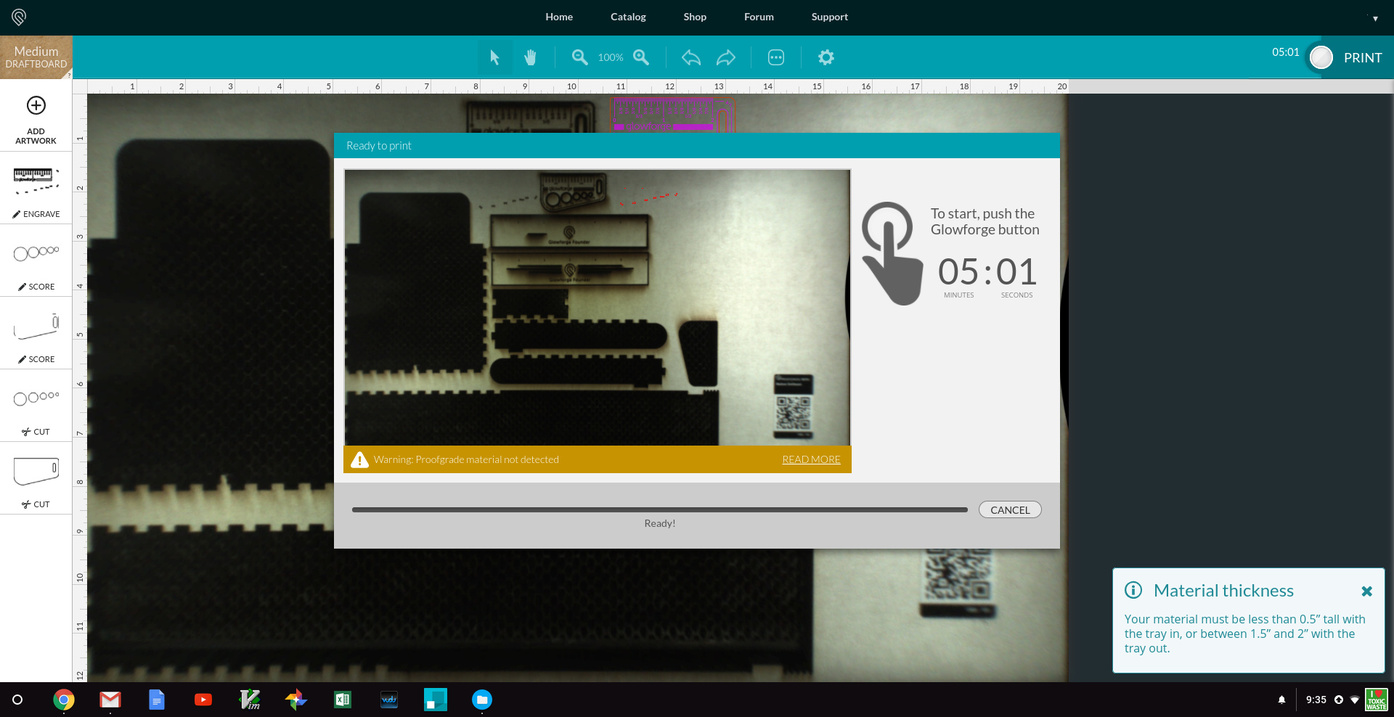

Repeated test run above. Started with positioning artwork

Selected Print. Received Material Thickness error during preparing design phase.

Print time 9:35 AM EST 2/12/2018

Same result as previous.

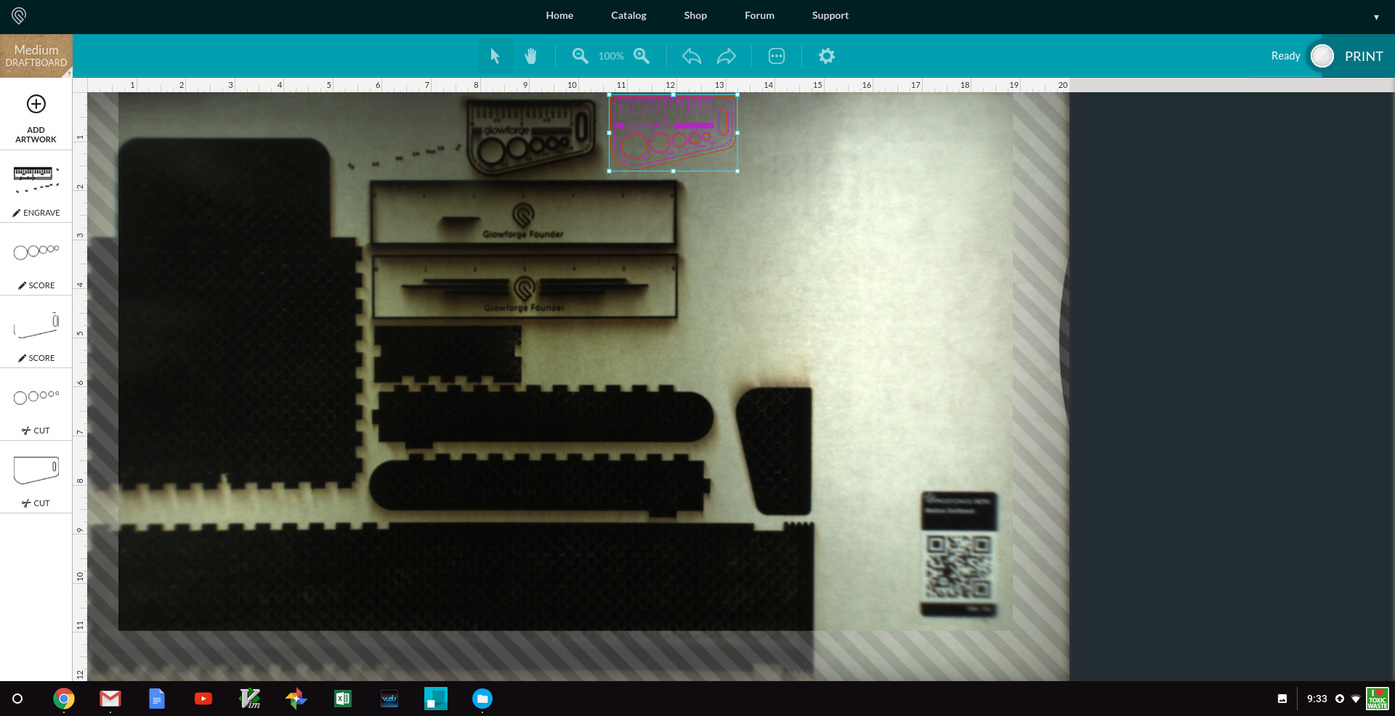

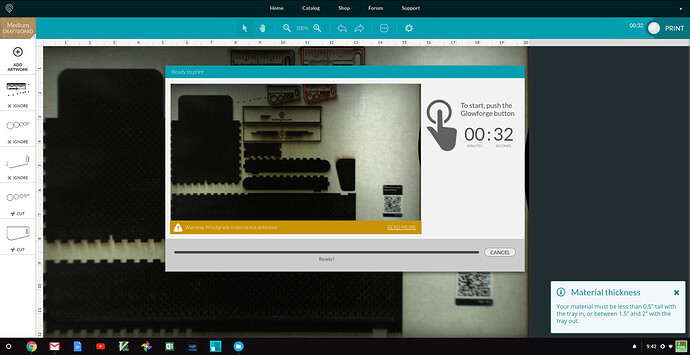

I proceeded to ignore engraves and scores and repeated the cuts.

Print time 9:42 AM EST 2/12/2018

Here are the results:

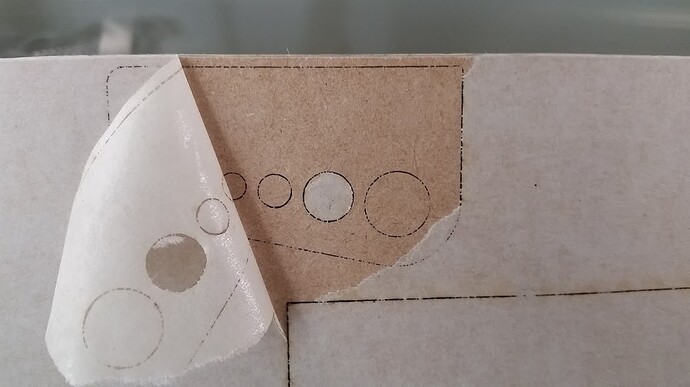

Backside with masking showing after second cut attempt. Note outline but not really cut

Better(?) view with masking peeled back. Definitely not fully cut.

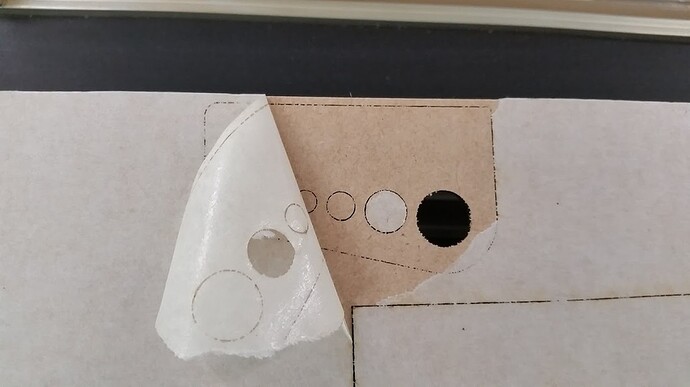

I was able to apply some force and pop one of the holes out. This just shows that while some penetration on 2nd cut pass it still didn’t cut to any quality previously displayed by the machine.

I await further instruction. Thanks for your attention.

I’m also leary about cleaning being the fix since the SD engrave came out great.

I’m also leary about cleaning being the fix since the SD engrave came out great. Perhaps I misinterpreted the HD Engrave as High Def when it should be Hardly Defined for this material.

Perhaps I misinterpreted the HD Engrave as High Def when it should be Hardly Defined for this material.