I’m not angry, I’m frustrated. I wasn’t yelling at anyone. Simply expressing my frustration that a product I paid a significant amount of money for doesnt work as advertised. I’m not quite sure why so many people are ok with that. Never once was I told that any of the features that were advertised wouldnt be available once I got the machine. That is, until I got the machine home and set it up and tried to do things. That’s pretty shitty if you ask me. But I guess if others have thousands to spend on stuff that doesnt do what they bought it to do good for them. I’m not someone who has that kind of extra money. The “oh, that’s just the way it is” mentality isnt something I do.

That’s not what I’m trying to advocate. You don’t have to be a doormat; but a “let’s make the best of the situation we’re in” mentality is definitely a healthier way to approach things than anger and frustration. The only person you hurt with the latter is you. (Sorry, psych NP can’t help but be a psych NP!) People are already doing amazing things with the passthrough even though the passthrough software isn’t finished yet, and you can, too. ![]() I don’t have one myself, but I know of a lot of users here who do, and who tend to bend over backwards to help others be successful.

I don’t have one myself, but I know of a lot of users here who do, and who tend to bend over backwards to help others be successful.

I understand where you’re coming from and you are correct. The issue arises from the fact that there is no steadfast go around for the issue I’m having. As I stated above there are things that work for some and there are things that work for others. I have tried multiple things to ensure that I got a good cut and they all failed. That’s where my frustration lies. I don’t mind using workarounds if there is one that works 100% of the time. I don’t have the time or finances to try a bunch of stuff that doesn’t work.

I recommend practicing on inexpensive material like mat board or cardboard a few times to get the process down. Make sure you are using the boots to lock the tray, and the honeycomb pins to keep the material flat, and make sure you have run the Calibration on the machine.

It’s pretty normal to run a few bad tests when you’re learning a new process. Try to do them on something inexpensive…it helps big time.

Everything is relative. Compared to machines for ten times the price, folks here have posted unbelievable work on the first day, while folk with other machines are still working on their college level engineering degree so they can accomplish anything.

That said nothing is magical, You can get perfect cutting and alignment but not without knowledge and planning.

The first thing is to make sure that your calibration is both done and very accurate, you can re-mask a sheet and redo if it is not perfect. Then you need to use the focus tool keeping in mind that it will be the most accurate where you pick, so pick where the lines have to join. When joining try to have as many places vertical as possible even if you end up with two six inch high cuts. Such places are far easier than a 10 degree angle as a half millimeter off will matter less.

Make both of your shapes in different colors and four quarter inch squares in a perfect rectangle of a third color and cut them first. before cutting more put a headless bed pin in the top two holes and cut the top part of the design. Then leaving the pins in place put the lower holes over them, This will keep the rotational alignment and left right alignment perfect.

At this point you can reset the focus and using only the up and down arrows (with shift for bigger jumps)bring the design into alignment. You can even have a couple of sacrificial squares outside the design but near the divide line so both can be scored to test for accuracy.

If you do all this and still cannot get it aligned then there are issues beyond the scope of machine or forum to help.

I certainly can sympathize with you for getting a Pro and paying the premium for it to be able to use the pass through. I didn’t get a Pro but I thought that cutting 1/2" material would be easy flipping over with camera registration. It is possible but it has been a long march to get to this point and it is still easier with jigs rather than camera registration.

The 1/4" limitation of the pass through and no automagic registration as you shove it through is a big challenge. I have tried it and understand the challenge.

That said, work-arounds are possible to get accuracy. It takes longer and you have to work on some registration system, either visual or physical.

Not sure if you are familiar with other lasers or not, but there are so many aspects of the Glowforge that make it easier to use than so many other machines out there. Just the facdt that the focus is automatic or at least controlled in software is huge. Many entry level lasers use physical measurement to get the focus correct and you have to go through a complicated routine for different thicknesses of material.

That said, if you bought it with the assumption that you could just stick a long piece of material in and have a design slice it up perfectly, it might fall short of expectations for sure.

This is super flawed logic. That’s to say that because someone else Was able to do something that the issue doesn’t exist. So if I have two working legs I should be able to run as fast as Usain Bolt? We have the same legs, even the same stride length. That’s ridiculous and you know it. The fact is that I was sold a machine that was promised as plug and play and that isn’t what was delivered. Sure there are go arounds but none of them are bulletproof and work 100% of the time for 100% of the people. otherwise this issue wouldn’t exist. This thread is the perfect example of that. There have been a few different suggestions as to how to “fix” the problem and they are different from one another. So now I’m stuck with a “smart” machine that I will have to waste time and materials to figure out. Not what I signed up for.

You must have missed my post before that. By your analogy considering the machine as legs you and Usain Bolt would have the same actual legs, however if you are considering mental ability as legs you might have a point.

I laid out a procedure that could produce perfect results if you used reasonable attention and care. I have a pro with the pass through and buy my plywood at 19x48 inch sheets as I get five of them per 4x8 foot start and cut designs that use two or three feet of them at a time. I plan so I can have a bit of error and keep it parallel to the right side of the crumb tray and have not needed the pin trick, but will if needed.

Just curious: is there current (i.e., within the last couple months, since you ordered your Glowforge) advertising from Glowforge claiming the pass through works automatically? I thought they removed that from everything until they complete the software.

The Glowforge Pro prints truly enormous objects like furniture with the exclusive Pro Passthrough, allowing you to use infinitely long materials. Upgraded solid-state cooling allows nonstop printing all day long. It offers all the capabilities of the Plus and Basic, and a double warranty. Class 4 laser product; place near a window for ventilation.

That doesn’t explicitly say either way.

- Pro Passthrough slot allows the use of material that’s up to 1/4″ (6.3mm) high, up to 20” (50.8cm) wide, and as long as desired

- Upgraded solid state thermoelectric cooling

This one also doesn’t really say anything and auto-alignment

I a not sitting on a chair made out of 1/4" material…

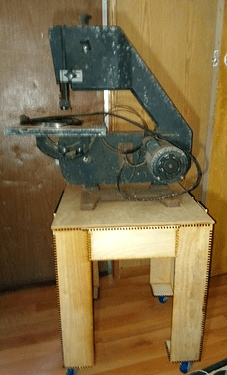

For all your massive amounts of creativity, you missed it here and forgive me if you were being tongue-in-cheek, You can easily layup thicker from thinner. Yes, I’d rather just cut thicker material on the saw and cnc but I’d love to see a chair done completely on a ![]() .

.

My brother once made a chair out of typical corrugated cardboard that a grown man could stand on without any concerns of it collapsing. Design + understanding your materials FTW.

I have a ~2" cube of interlocking medium draftboard that I can stand/balance on. I’m also heavier than the average grown man…

Not a chair but complex geometry can be as strong or stronger per pound than thick solid wood.

I recall some friends with a 50’ trimaran that the style needs a massive crossbeam to keep the various hulls from tearing it apart. The beam was 24" x 30" and the 45’ across the width of the boat, but the 24" width was 10 half-inch thick ply equally spaced making it far stronger and way lighter than if it had been solid.

My experience is with airplanes but yeah, I’m sure boats are the same.