We have had the machine for maybe 2 weeks. I know that cutting other material than proof grade requires some testing, trial and error. So I sat down to test and try until I nailed it down to the cut we liked.

We are using 1/4" pure bond birch plywood from Home Depot.

After my day of trial and error and lots of non cuts, I thought the non cuts were user error. So, I set forth using the machine. It worked for a day (2 or 3 cuts) and then started not cutting. I turned it off, cleaned it, turned it back on and it worked for another cut or two then quit cutting through. It leaves a super thick burn mark that is no where near through the material.

Turn the machine off and clean again, works for a cut or two then quits.

Tonight I sit down, again, to hopefully do about a dozen SIMPLE cuts. Nothing fancy, not a lot of detail. A few big circles and big pumpkins. I am not using the passthrough.

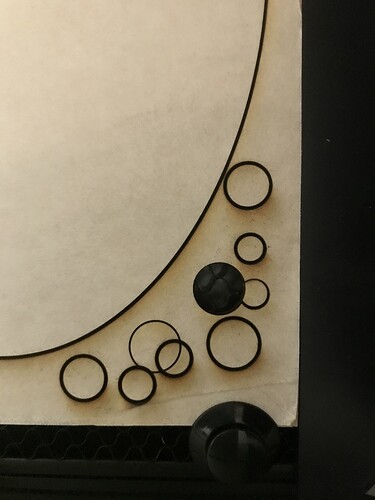

I drew a circle in the software, it cut through. I hit cut on the design, as you can see in the photo, fat line and it did not cut through. Draw another circle and it did not cut through. Turn machine off, wait a few minutes, turn machine back on, close and open software again. It cut through a circle. Move circle to just next to the cut circle and it did not cut. Big fat line. Turn machine off again. Back on. Same thing. It cut one circle and then quit.

This is not a material issue. This is a machine or software issue IMO. It has done this same thing since we got it. Only it cut a few times before it quit working. I spent over an hour cutting circles out of a piece to fine tune the settings. They work fine one moment and not the next.

We have also cut at 152/95 and had the SAME problem. Tonight I was trying to speed things along and it worked on the first try at 210/full. Great. Let’s whip some stuff out. Then it went to not cutting and giving the fat line until we turn the machine off and back on. I should not have to turn it off to make it work after every single cut.

I have emailed support so they will probably close this thread with no answers. But hopefully before they do, someone else can chime in and give some thoughts, opinions or some good jokes to make me laugh because right now I feel like I have a $6,000 boat anchor.