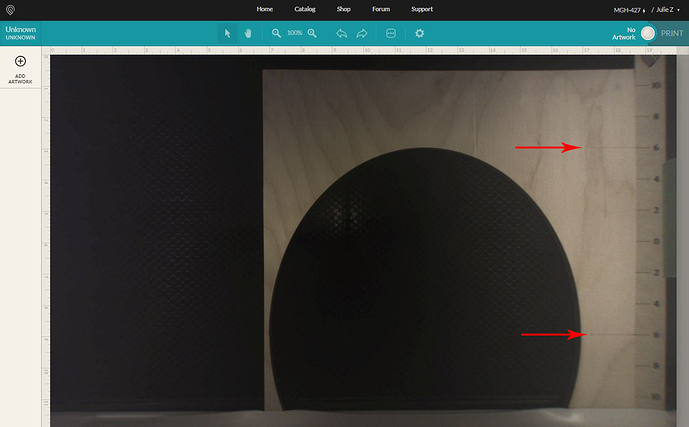

So I got my Pro right before Thanksgiving. I won’t go into too much detail since there are still folks waiting, but…Wowzers!..Yes, it was totally worth the wait. ![]()

I had an unrelated computer issue that kept me from playing with it for a couple of days, but i got that squared away, did a little Christmas gift prep, and finally got around to trying the passthrough slot for a couple of small test runs.

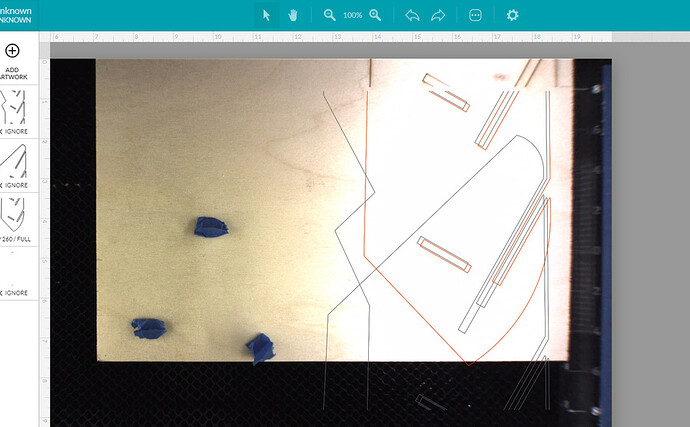

I essentially used the method laid out by @johnse here, Passthrough Alignment with Manual Indexing, and got absolutely excellent results, so I highly recommend it. It has the advantage of not relying on the lid camera for placement, so until the software gets finalized, we can still knock out what we need without waiting.

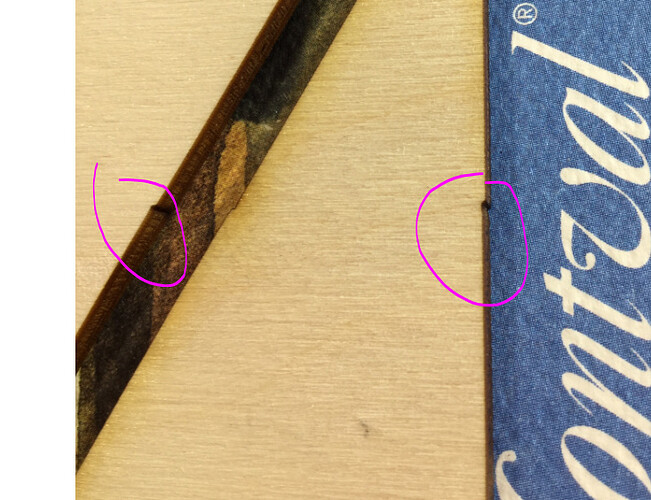

If you have a machine that has camera alignment that is still slightly off kilter, you can use the tutorial method with a sacrificial side scrap to actually run the indexing scores across both pieces of wood…that is going to be completely accurate no matter how badly the camera alignment is off, because you don’t use the camera at all. (Make sure you tape the scrap into place though, you don’t want that piece to move at all.)

Once the machines have achieved final tuning, I thought that something like the file below might come in handy, for those who don’t want to keep a scrap of wood lying around. You can build your files on any index from zero to ten inches, and then use the guide taped into place to anchor your material against. I like to index off the right side, but there are left-side templates in the file as well… just delete the ones you don’t want to use. (And if you set your artboard correctly, you can place the lines in the design so they land right up next to the jig. Bonus! ![]() )

)

Since these will print accurately, and your files will be created with the same accuracy, they actually worked just as well for me as the score across the two pieces of wood. I wasn’t expecting that, but it turned out fine, so i thought I’d share them.

Passthrough Jig Templates2.zip (12.1 KB)

Cheap hardware store 1/8" ply…no sanding. Turned out pretty good. ![]()

More detailed instructions here:

And here for Inkscape: