Glowforge Pro machines have Pro Passthrough slots in the front and back that enable printing on infinitely long materials to create truly enormous objects.

Update 11/27/2020: All Pros can get Pro Passthrough software!

All Pros are now able to use Pro Passthrough software. Read more about that in the Glowforge Community November Announcement here.

Before running your first Pro Passthrough print. make sure to read the Pro Passthrough tutorial. Please keep in mind that each section of the print will usually auto-align, but sometimes it doesn’t and you’ll need to align the next section of the print manually.

If you run into issues using Pro Passthrough with Proofgrade materials, please contact us directly at support@glowforge.com or make a new post in Problems and Support. I’m going to lock this topic so folks don’t accidentally post here for help. Moving forward, we’ll share updates on Pro Passthrough in Latest Improvements.

We really appreciate all the feedback you have given us on Pro Passthrough. We want to continue hearing your feedback, so we’d appreciate it if you filled out the survey that appears that appears after each Pro Passthrough print. We’ll use your feedback to help make Pro Passthrough even better.

Old announcement here:

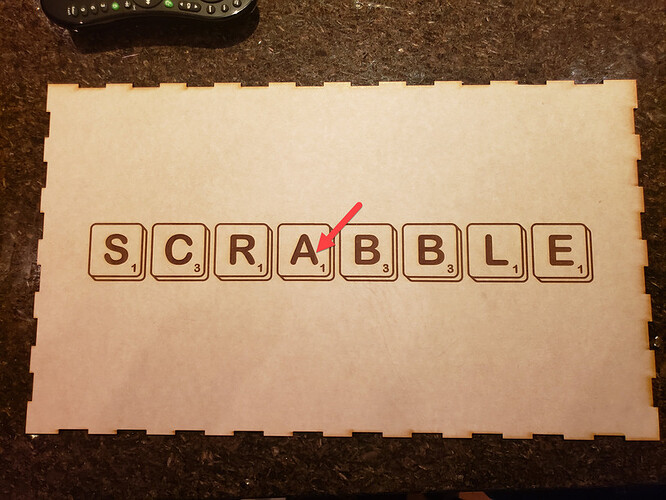

Pro customers have been using the Pro Passthrough slot for years to make amazing projects using techniques like this and this.

Now we have a beta version of the software that makes it much easier to prepare large prints for your Glowforge Pro. It automatically slices your design so you can create something enormous with a series of individual prints. Depending on your machine, it may even align each section of the print with the previous one, automatically.

Because we’re enabling new software and hardware capabilities on a variety of printers, we’ll be performing this beta rollout slowly. We’ve mostly tested with new machines from the factory, so we’ll adding older machines in waves as we develop additional compatibility tests and software. We’ve turned it on automatically for machines purchased after 6/25/2020.

If you’d like to test Pro Passthrough beta when it’s ready for your machine:

- Read this tutorial: https://glowforge.com/support/topic/first-three-prints/pro-passthrough

- Fill out this form: https://forms.gle/MY9ENkpeUTWiT56i6

We’ll let testers know by email when we’ve turned on the software for them.

Our plan is to launch Passthrough software to all Pro customers after we validate and improve on it with initial beta testers.

If you are a beta tester, we would love your feedback - Is it working? Is it useful? Is it confusing? Is it enjoyable? We encourage you to fill out the survey that will appear after using Pro Passthrough. You can also leave your comments right in this Pro Passthrough beta thread. Note that our customer success team won’t be able to answer questions about this feature yet, so you can also use this thread to ask questions or get support.

Here’s a brief FAQ.

How does it work?

First, turn on Pro Passthrough mode and insert a piece of oversized material so it sticks out from the back.

Then, place your oversized design on the bed. It can extend past the top.

Start your print. It will print everything in the printable area, then take some additional measurements.

Move your material when prompted, about 8 inches towards the front of the machine.

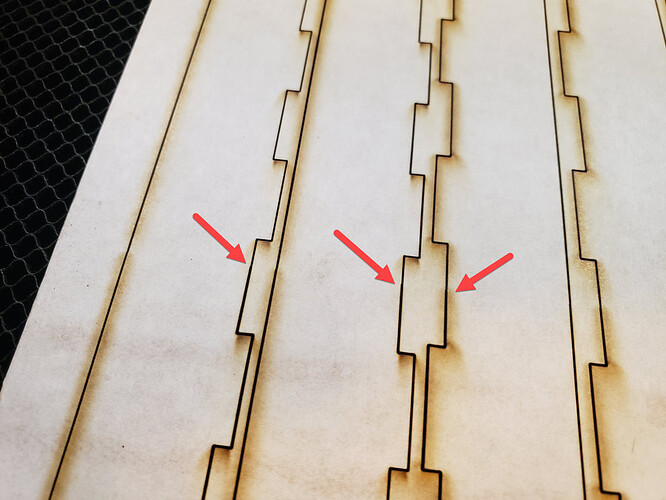

It will measure the material again and attempt to line up the next part of the print with the previous. If it doesn’t work, you can align it manually.

Continue with the second part of the print, and repeat until finished.

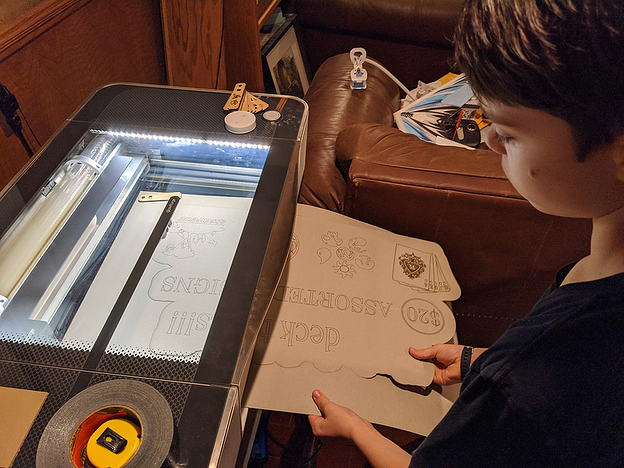

It’s pretty easy. Just ask this guy:

Is this coming to all Pro units (like 3x faster speed), or will you stop the rollout (like Snapmark)?

We plan to launch the automatic slicing ability to all Pro units. We expect newer units may experience better automatic alignment than older ones, but we will launch automatic alignment to as many units as we can. This beta, and your feedback, will help us understand how well it works so we can better plan our rollout.

When will I be chosen?

We have changed details of our manufacturing and calibration process over the years, and we’re bringing people in based on the details of how their machine was built at the factory. As we need people in different groups for testing, we’re adding them. Some folks are added immediately; others may wait until their machines are needed for testing - we don’t have any estimations of how long that may take.

Can I get this software on my non-Pro unit?

No, we’re making this a feature exclusively of our Pro model.

I really need it! Can I get it sooner by asking support?

No, unfortunately that will just tie up support and slow things down for everyone.

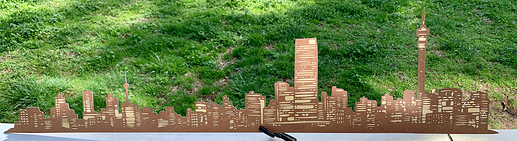

How big a print can you make?

Pretty big.

(Print courtesy @evansd2, 12”x600”)