I would buy a grab bag of “waste” Proofgrade material.

Ditto!

Very good idea!

How small a waste strip would still be useful? Probably anything down to inlay strip, although positioning might be a bear. (That’s sort of an interesting question for general use too – when I’m planning cuts on a piece of wood, for example, I always leave room for slop and possibly sanding, and enough to hold the piece without my fingers or the clamps getting too near the blade/bit. And pieces have to be big enough not to break while cutting. With a laser, those constraints are pretty much gone, except maybe a little bit of sanding for the char if you want to get rid of it for the materials where that’s an issue.

I think he is talking about how material break down works in a cut plan a 4x8 plywood doesn’t break down to 12x20 with out 15% (just picking a number) or so waste but a 10x18 does break down from a 4x8 with less waste. ill do a cut lay out it a bit playing some WOW atm

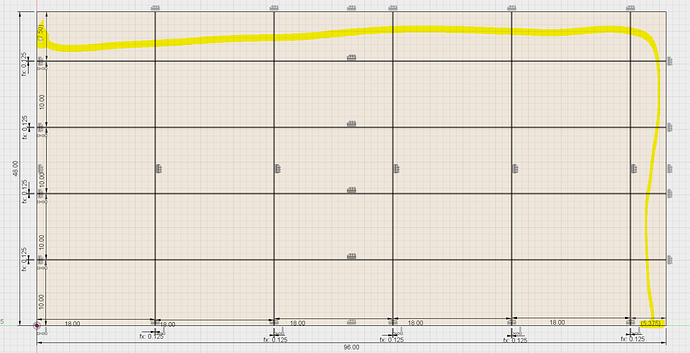

14 12x20 = 37% waste

14 12x20 = 37% waste but one could argue that 11.625 is close enough to 12 but I just don’t know if dan would be able to sell that if marketed as 12 but if we say 11.625 is close enough that brings it to 18 usable pieces for 6.67% waste

15 12x20 = 28% waste - +1 (16) if 11.625 included 20% waste

20 10x18 = 28% waste

23 10x18 = 11% waste

Correct - kerf’s a bitch.

That’s why most wood is actually nominally sized (drying also causes shrinkage but for laser materials like Baltimore Birch ply it’s the kerf). I buy a lot of 12x12" that’s really 11 3/4 square. The manufactured size of a sheet of BB ply is 60x60" and anything smaller suffers kerf loss.

If they used a Really Big Laser, kerf loss would be less

Interestingly, 60 inches is evenly divisible by both 12 and 20, so you would be able to get 15 full bed sheets out of one of those with no waste. Well, technically once you account for the kerf, each panel would be about 11.9" x 19.92", but zero waste is nice! The only trick is finding a supplier of the higher-quality Baltic birch without knots or voids in the middle layer(s) and laser friendly glues, since I know I’ve seen it mentioned here in the distant past that not all Baltic birch is created equal.

True, but a laser is an incredibly inefficient way to cut plywood to size in quantity. A really big saw can cut stacks of plywood feet tall vs one (or even a few) sheets at a time.

Have you checked out Windsor Plywood?

I’ve been using the birch ply from woodworkers source…its been pretty good so far

I consider myself very lucky to have a Windsor Plywood in Bellingham, I do as much shopping there as I can.

The only problem with that (for Canadians) is the Softwood Lumber Dispute. I think that lots of Canadian forgers are going to find shipping wood up from the US is going to be very expensive, especially when there’s plenty of very good suppliers here in the country.

And it’s not going to get better…

In November 2016, CNN obtained a leaked memo from the Donald Trump transition team showing that Trump was being advised to include the softwood lumber dispute during any renegotiations of the North American Free Trade Agreement and to get more favourable terms for the United States.

That’s exactly where I planned to be getting it, I suspect they have the good stuff.