I haven’t had to do that yet, thankfully. Was it a broken wire or an actual thermistor failure?

I haven’t taken the multimeter to it yet, but I suspect the wire. Just was responding to mintemp error and the fact that I could jiggle the wire and the led on the bed would blink. The temp graph looked like Nepal, spiking on and off but never long enough to trigger the error. Then I started jiggling it and then it must have broken inside.

I had to replace one already. This time I bought a pack of five. The ones I got off Amazon, where the review swore they were exactly perfect for a Prusa MK2 didn’t have a normal dupont end. I was just about to order a set of the parts and crimper the other day, but held off. So it was delicate surgery to remove the original dupont connector and put it on the new wire. Managed ok and the temp is reading accurate at least to my IR thermometer.

So I realize I do get a lot of satisfaction when I fix something that gets borked. Especially if I had saved some bucks on the purchase. That’s a thing with me so I am willing to overlook some lack of features because I have some personal investment in it. I guess that is why I like Open Source stuff so much. There is that sense of superiority. It’s like command line computing. It puts you above the common crowd.

I think it’s like the law of intermittent payoff that keeps golfers and gamblers coming back for more. That one perfect stroke or the one hole is what we remember and the lost balls and triple bogies just fade away.

Glad you enjoy it! I suspect because I expect my printers to make money the stress of dealing with that crap when it happens takes all the enjoyment out of it for me. If the printer can’t pay for itself there isn’t a reason to get it.

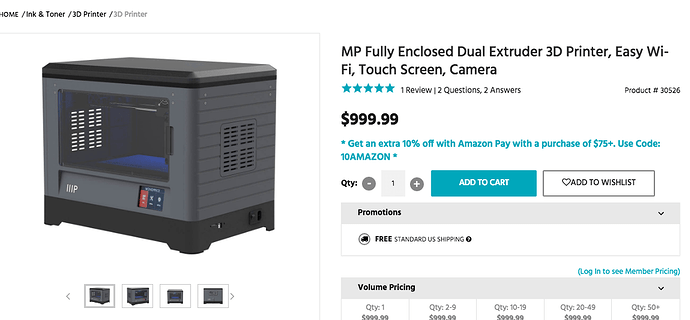

The flashforge is a Clone very similar to mine. I paid 1300 for mine when Monoprice first came out with theirs.

The bad. There are a few weak spots I found. The y axis wires in mine were not in a cable snake. My y axis motor mount was broken when I got it. glued it together and printed a replacement. Monoprice did sent me an upgraded one. After two years one of the wires broke inside the insulation. No sweat, just spliced the wire and continued until i finally upgraded the arrangement with a cable snake i got cheap off Amazon. (I cut the parts for that on the Glowforge).

Today the Printer Gnomes and I are Having a “Chat” The heater bed wire connector on most of these can be a problem. Mine was arcing so I just soldered the wires directly to the bed and tied them off with a wire tie. At the same time I had some wires fail that drive the filament feed motor. I happened to have some replacement connectors with wires on had so I replaced the first 6 inches where most of the wire flexing happens.

Occasionally you may need to open the feeder motor and clean the toothed gear. I do it usually once per spool of material. The stepper motors are bog standard.

The good.- I have printed a lot of stuff on this printer. I run ABS exclusively, and it has been a workhorse for me. I do a lot of prototyping and sometimes the printer runs for 10 or so hours a day straight. This one is fully enclosed, mine isn’t. I sometimes run with a garbage bag on mine to keep the drafts out. It’s odd to think that opening a door in a room or the cycling of the AC would alter a print, but with ABS it can!

I’m considering buying another FDM printer myself, and may just pick one of these up.

I agree! If you want plug and play, buy a Dremel. If my 3D40 can survive over two years of high school students with only one clog (which was my fault) I think that speaks volumes. Their tech support is fantastic. I’m usually running one to two prints per day and it’s been great. If I were buying a new one for my school, I would get a 3D45 for the heated bed.

That said, I just bought a Reliabuild3D for my home shop and am really pleased with it. I didn’t go with a Dremel because I wanted a huge build plate and wanted the experience of building it myself so I would understand how to fix it, and be able to upgrade it down the road.

Thanks for the info. I am leaning towards thia one but I am afraid I might just be impressed by the way it looks .

I need to make sure I understand the differeno filimenrs and which I would use more —

Does anyone have experience with the Raise3D-Plus-Printer-Dual-Extruder

It seems a reach for a 10" to 4" connector from Glowforge to blue whale but then there is a lot of other things to make and does not have to all be the biggest possible.

ABS has worked the best for me, so well, I print almost exclusively in it.

PLA is good to start with and is more forgiving to print. ABS does weird things with warpage and will give you no mercy, but once you get to know your printer and play with temps the results are quite satisfactory and the parts are really durable. ABS sands up very nice, and can be chemically polished with Acetone, either with the vapor method, or just wetting the surface with acetone using a brush. one of the biggest drawbacks to PLA was the difficulty to finish it out after printing for me. It does not sand well, and the Acetone trick does not work very well. PLA parts are very serviceable, but the model work I do demands a better finish than I can achieve with PLA.

By all means start with a roll of PLA, and graduate to ABS. It’s kind of like the difference between Proofgrade and “Uncertified Materials”!

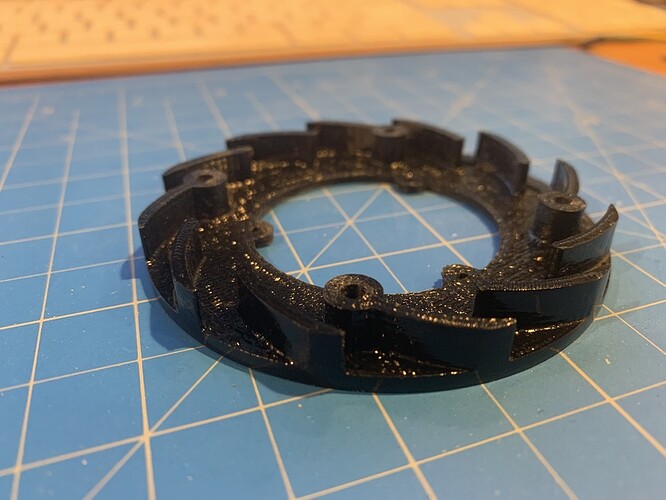

Here is a part that just came off my printer after 220 sanding and an Acetone wash.

I took the picture with it upside down, you won’t see the roughness of the “Roof” in the final assembly, so I didn’t bother finishing it.

I do too. One of the issues with PLA is that it can get soft in hot environments like your car in the summer.

Some people don’t like ABS because it helps to keep the printer enclosed while it prints and there’s some noise about it having some toxicity issues - but those have to do with ABS in it molten burning form and not its cured form. PLA is non-toxic so there are people who pick it just for that reason.

The main types of filament in use are:

PLA: Poly-lactic acid. This is a bio-plastic, meaning it will degrade in about 100-150 years under normal environmental conditions. It has a low softening point, so it will deform in your car on a hot day, especially if it is in direct sun. It is strong, but brittle. It can be carefully heat treated after printing to temper it. Glue with superglue. Easy to print.

ABS: Acrylonitrile butadiene styrene. This is what most people are familiar with as plastic. High heat tolerance, lower strength than PLA, much higher impact resistance. Releases toxic fumes during printing and stinks, though you can get low odor formulations. Can be vapor polished and glued easily. Hard to print due to thermal stresses causing warping.

PET family: Polyethylene terephthalate. A polyester family material, comes in variants like PET-G, PET-T, CO-PET (Amphora), and others. Good strength, fair to poor impact resistance, depending on formulation, higher melting point, between 75 and 100 C for most, some as high as 110 C. Glue with acrylic solvent glue or superglue. Can be food safe. Relatively easy to print with.

Nylon family: A polyamide material. High strength, low stiffness, high impact resistance. This material is slick and can be used for bearing surfaces. It is extremely strong and tough, but will bend and flex. I haven’t broken a nylon part yet. It is hard to print with as it likes to warp.

I personally use CO-PET the most. PLA is the most forgiving and can be printed with an open printer. PET can be printed with an open printer depending on your model and type. ABS and nylon both need a closed printer.

There are many others, including rubber type materials, and exotics like PMMA, and fiber-filled variations of most standard materials. Fiber filled materials require special equipment as they will destroy normal nozzles.

I don’t smell any odor from ABS unless I have my nose right up against the nozzle while it’s printing. I have a very good sense of smell otherwise, maybe this is just a blind spot for me…

It will depend on the formulation in the ABS you use. Generic ABS smells like burning plastic to me and I will smell it for days in my house. The low odor formulations are much better, I will only smell it if I leave and come back to the house, but the odor lingers for several days after printing.

Well…I’d love to have that one! Wow…I don’t have that kind of dough yet!

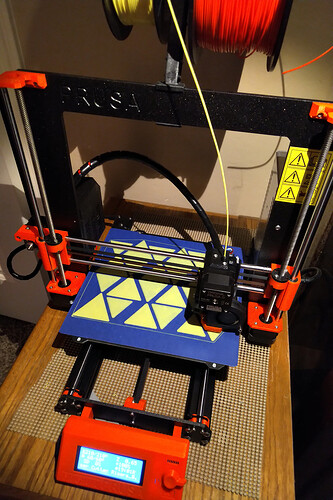

i use the Prusa Mk3 quite a bit - i have 4 3d printers and that is my favorite - here it is printing stand off pyramids supports for thicker materials in my glowforge

Prusa is at the choice so far…I was hoping for an enclosed one but this one has more yays! Hoping to order on or before Friday.

Friday is my 24th 30th birthday.

If turning 720 isn’t an occasion for a 3D printer, I don’t know what is!

I saw one of these in action the other day and was pretty impressed with the quality of the print it was producing: https://www.creality3d.shop/collections/3d-printer/products/creality-ender-3-3d-printer-economic-ender-diy-kits-with-resume-printing-function-v-slot-prusa-i3-220x220x250mm

Wow! next Friday is my second 36th birthday And my second without a Glowforge since I bought it. That Raise 3d is where I would like to go if It could somehow pay its way.

I am way to old to operate a 3D printer, huh?

I stopped counting at 30! I will be 54 on Monday.