I agree that the store has the potential to become a mess if it’s not implemented. If we do not have a method for adjusting designs to material width, we at least need clear guidelines on how to post our designs to handle this (perhaps have several copies of the designs for several different widths we support).

I like your ideas of using color for lines that need to be resized. But I do have reservations about how practical it is in real life. I know when I do a design in InkScape, one shape has one line color. I can’t easily say “this line is this color”. I can always break that shape up into line segments, but it’s a pain in the neck to do so, and it has other negative consequences.

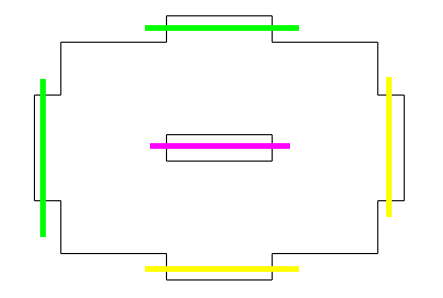

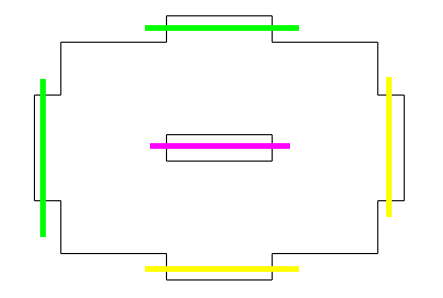

I’m wondering if there’s not an easier way to denote which lines need to move when resizing. Perhaps a layer above the cut layer that has lines that intersect the lines to resize (with 3 specific colors, one for right/bottom justify, one for left/top justify and one for center justify). Something like:

In essence, we are defining a standard for “parametizing” an svg file. I was really hoping that something like this already existed, and we did not have to define it ourselves.

I know a lot of people are saying: “just use Fusion 360 or some other tool that already has parametric designs”. That’s fine for making my own designs. I already do that.

But if I’m selling a design on the design store, I can’t assume that the person who is buying it has that same tool installed, knows how to use it, or has the time to figure it out. We want the store to be as easy as possible to use. I don’t think it’s reasonable to ask customers to download and install Fusion 360, open the design, change the parameter, save the proper sketch as a dxf, open that sketch in Inkscape, resize it, color the lines we want to cut vs the lines we want to raster, etc. etc. etc. There are a LOT of steps between Fusion 360 and having a cut file that is usable.

I would much prefer to just put up an SVG file on the store, and have a quick GUI interface the user can use to adjusts the design for material width (or something that does it automatically if they are using proofgrade material).

An SVG file is just an XML file, so it should be possible to come up with a program that does this, given the right standards. I’d be happy with a program that will work for 99% of designs. Someone will always be able to make a design that will just not resize properly given our standards, but those are the edge cases.

Sorry for the long post.

)

)