[Edit: Changed title to be a better description based on further experiments]

It’s been a while since I’ve posted in the forums. Unfortunately I’ve hit an issue that I seem to recall was also present in some units in the early days, but I don’t recall if there was a specific fix.

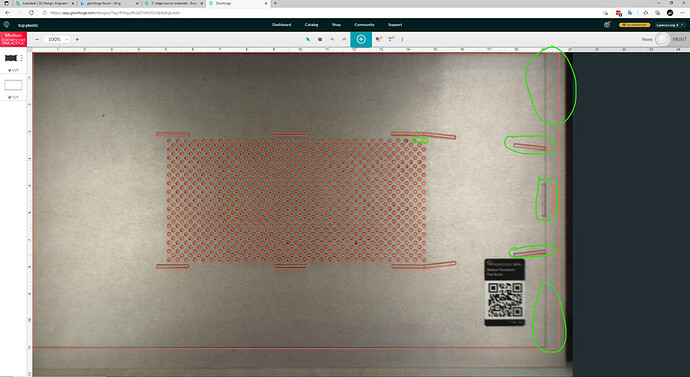

I’m cutting a large design–maximum size 494 x 278. But it hit the right limits while printing. In measuring actual vs. design, the whole x scale seems to be off, causing it to hit the right end-stop and then print everything after that offset in x.

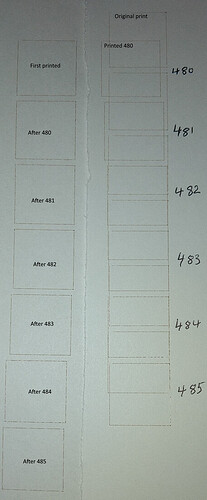

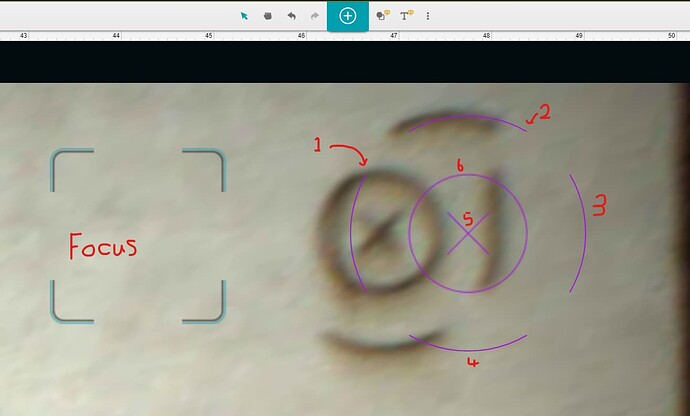

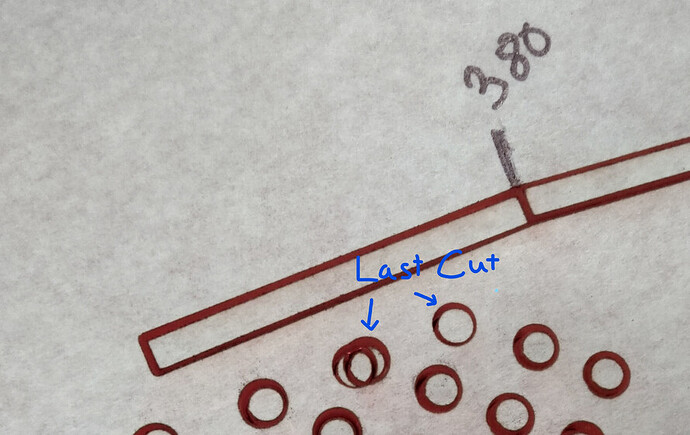

A couple of pictures. to help explain First, the design and as printed from the app:

You can see that the design has space between the right-most holes and the edge. I heard it hit the endstop when it moved to print the lower rightmost angle rectangle. It then printed the three small rectangles and moved to print the last 2 tiny holes (upper right of the grid). Note that these printed shifted to the left.

It then moved to cut the outer box.

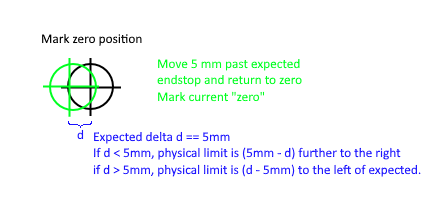

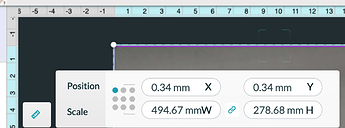

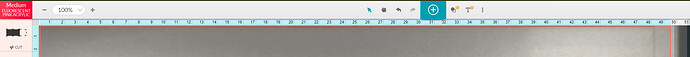

Measuring the outer box, it is 494 mm. So I started looking at other things. Here’s a snippet showing the design against the mm ruler in the app:

Note that the leftmost rectangle starts about 116mm and the joint between the rightmost two boxes is about 367mm.

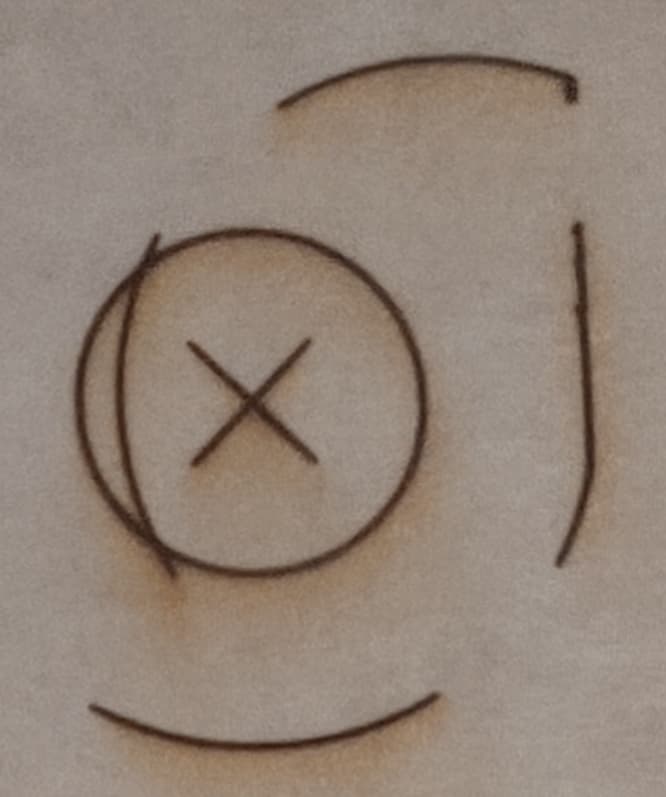

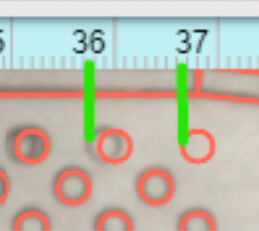

Compare that to the actual printed measurements (measured from left cut line):

measuring in the Y axis seems to be fine.

The design was created in Fusion 360 and exported using the Shaper Origin tool. The SVG was directly imported to Glowforge (and then changed to “cut” instead of engrave for the outer box).

This was the first thing printed today, 6/26/2021, roughly around 3-ish.

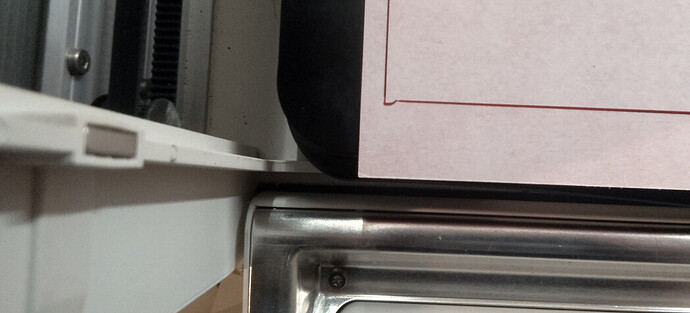

NOTE: I cancelled the print when it started cutting the outer box since I suspected it would be printing off (since it was printed last). I restarted the print with just the outer box selected. When it started the cut in exactly the same place, I restarted the Glowforge and tried again, with the same result, so just let it continue.

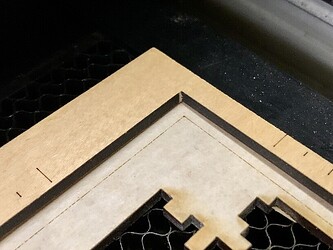

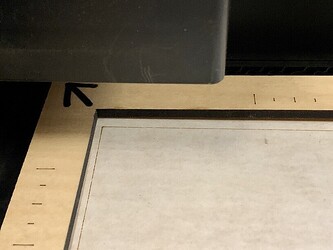

There was also this odd squiggle at the lower left corner:

What can I do to get the X dimension properly calibrated?

Update…I just had my coffee, and I’m actually awake now, so I wanted to mention that the “zooming in” is critical before you nudge. At higher (like 450% and up ) magnification, the steps are smaller than they are at 100% magnification. So you might still be able to shift it over a little to the left.

Update…I just had my coffee, and I’m actually awake now, so I wanted to mention that the “zooming in” is critical before you nudge. At higher (like 450% and up ) magnification, the steps are smaller than they are at 100% magnification. So you might still be able to shift it over a little to the left.