My pro is smoking from underneath, not cutting through and dark lines, some flare up. It was fine then a little smoke coming from front where foam is, the foam is coming out a little, so I taped it, then it came out bottom. Any ideas on quick fix. Customer service took way to long last to to respond and correct issue. I I’d email them . thanks.

If you have the compact filter, I would guess the filter is full. If you are venting out the window, I would guess your exhaust fan needs to be cleaned or the hose is clogged.

Also:

-

Don’t tape the seams. They’re open on purpose, for air flow.

-

Posting in Problems and Support opens a support ticket, so you did just communicate with Customer service.

No i dont have the compact filter, I vent out a window

Do you hear the main exhaust fan start when you start a job? It’s really loud.

If it is running, then it must either be really blocked, or there’s some blockage in the vent.

Even a really dirty fan should easily exhaust smoke enough to prevent it coming out thru the inlet fan.

Have you inspected it per the troubleshooting info?

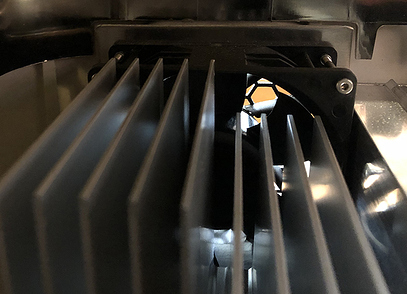

It sounds like it might be a clogged grate behind the exhaust fan. Remove the hose from the back of the machine and check to see if the grate behind the fan is clogged with crud. Use a pipe cleaner and a vacuum attachment and brushes to clean it out. (Also check the hose to see if there is anything clogging it, and any outlet ports.) Also check that the air intake is clear at the lower right hand underneath the machine.

*After turning off the machine of course.

Sounds like you head fan is iffy as well. If there is flare up it interferes with the cut so it does not cut through. If the fan is working well it is blowing smoke away fast enough it will not go to flame.

Something interfering with the air flow, or a strong magnetic field will allow the flaring, as well as a dirty head fan. I use a shop vac to pull air through that head fan and spray hand sanitizer in the fan to dissolve the crud and run the shopvac for a half hour after to be sure all is evaporated, all while the Glowforge is completely unplugged,

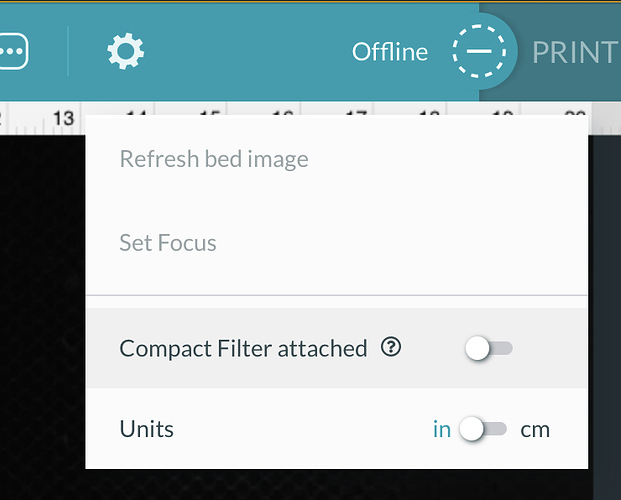

And the last thing to check is make sure you don’t have Compact Filter Attached selected under the gear icon. It should look like this:

If you have it selected, the exhaust fan will not clear the smoke. It is intended for use only with a Compact Filter.

I’m so sorry to hear that you ran into trouble.

To help troubleshoot your exhaust, could you send me a few photos of your exhaust system? Specifically, please include pictures of the following:

-

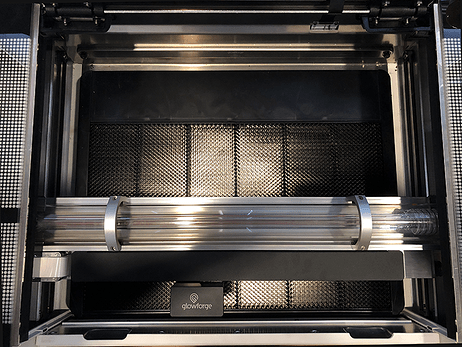

The exhaust fan from the inside of the unit. To capture this photo:

-

Turn your Glowforge off

-

Open the lid

-

Using both hands, gently pull the printer arm towards you as shown below:

-

Move your phone or camera inside the Glowforge on the left-hand side, past the metal rail, pointed away from you towards the exhaust hose, to capture a photo like the one below:

-

A photo of where your exhaust hose attaches to the Glowforge, where your exhaust hose exits the room, and the path your exhaust hose takes from your Glowforge to the exterior vent or Compact Filter

-

The exhaust connection on the back of your Glowforge, with the exhaust hose removed:

-

Any area where you see smoke escaping from your Glowforge while printing

Once I can review the images of your exhaust configuration, I’ll send over the next steps!

I cleaned the fan behind the printer head, seems to have helped. Here are pictures. Can I get a new piece of rubber for the front drop down where the pass through is? Mine is falling apart along with the rubber strip.

Thank you for cleaning that! I’m glad to hear that it made an immediate impact.

When referencing the rubber, are you inquiring about replacing the curtain underneath the front pro shield, or the rubber foam that is in-between the bottom of the inside of your Glowforge, and the bottom of the door?

@citygirlpaints was able to contact us directly via email, and we are working on it there. I will now close this topic.