Thanks for your patience.

I extracted the logs to investigate the problem you reported, and I believe I found two separate issues that have been contributing to the inconsistent results you’ve been seeing.

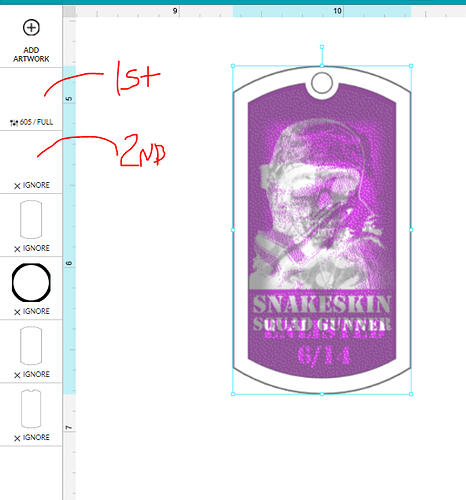

The first issue relates to the autofocuser that happens when the app says “Scanning your material”.

When working as expected, the print head moves over the area where the print is going to take place and shines a low power red laser we use to accurately detect the material height, and focus the main laser.

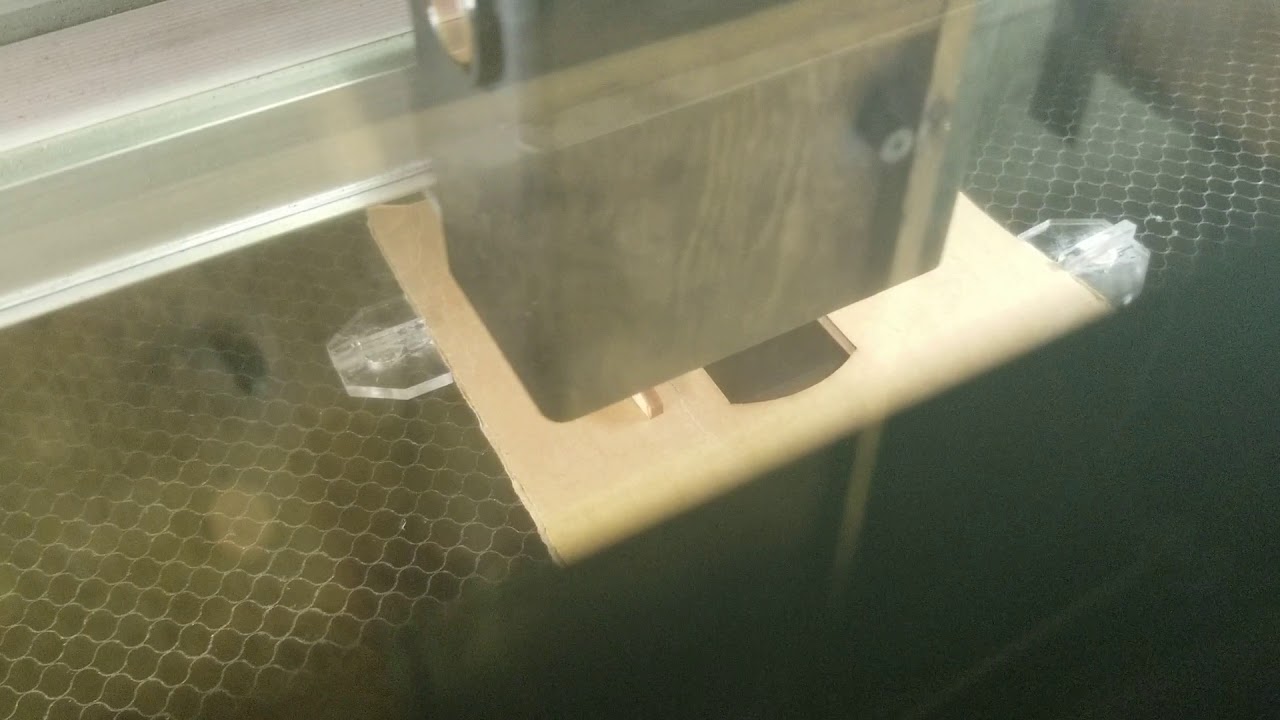

In your case, the red laser was striking parts of your jig in unanticipated ways that was causing incorrect results, which in turn was causing poor laser focus. This poor focus is the cause of at least some of the the inconsistent results you were seeing.

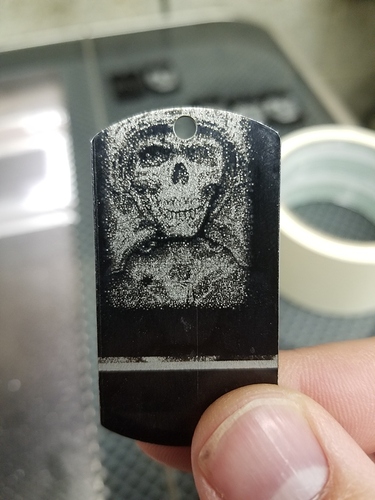

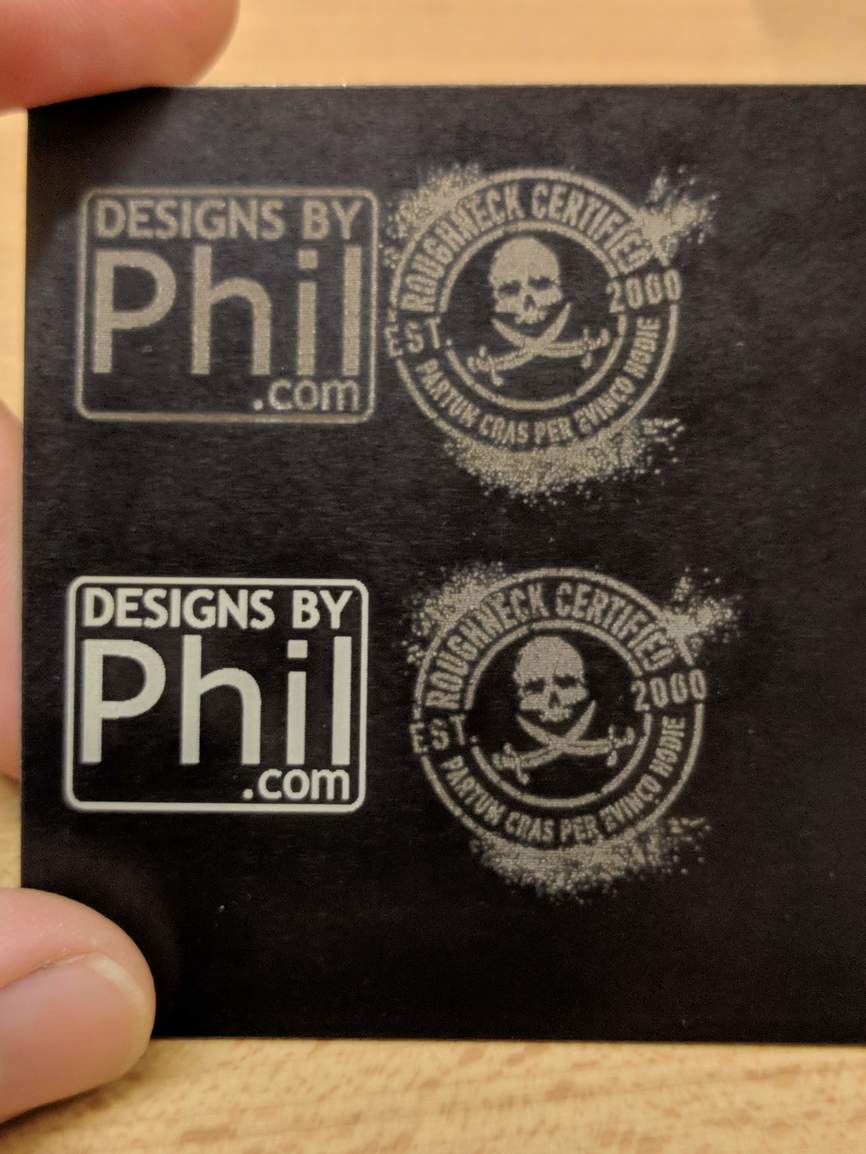

I ran a couple tests here in the office using your designs, as well as the settings extracted from the logs.

(Vector on the left, raster on the right)

In the first test (the top two), I simulated a focus error of about 6 mm (based on the logs from one of your prints.)

And for the second test (the bottom two), I simulated a focus error of about 3 mm.

What to do about it:

You have a couple options to work-around this issue:

Option 1: Make sure the autofocuser is measuring the correct spot

-

Make sure the red laser mark strikes the surface of the material you’re trying to print.

-

If you see the red laser mark hit something else (at at different height), cancel the print and make changes to the design, the setup, or the layout and try again.

Option 2: Manually set focus

Regarding Vectors and Rasters

Our software handles the engraving of vectors and rasters differently.

What to do about it:

Depending on the design you’re working with, it might be easier to use design software to convert vectors into rasters, or visa versa.

I hope these details help you get more consistent print results.