I imported a third party DXF into Inkscape and cut it on Glowforge. There was outline text, a text letter that had stroke but no fill, used to number pieces. e.g. “C2”. Since it was an outline I could only use ‘score’ or ‘cut’. I chose ‘score’ and got some crazy results. Simple characters like ‘A1’ came out acceptable but with visible double burn on the corners. Other characters like ‘C2’ cut completely through the material! All the characters were on the same layer in the app and used the same setting.

When I investigated the source file and zoomed in all the way I noticed that the ‘C2’ characters were split into tiny straight line segments. This is really zoomed in so the line segments appear thicker than longer even though they are 0.005" stroke.

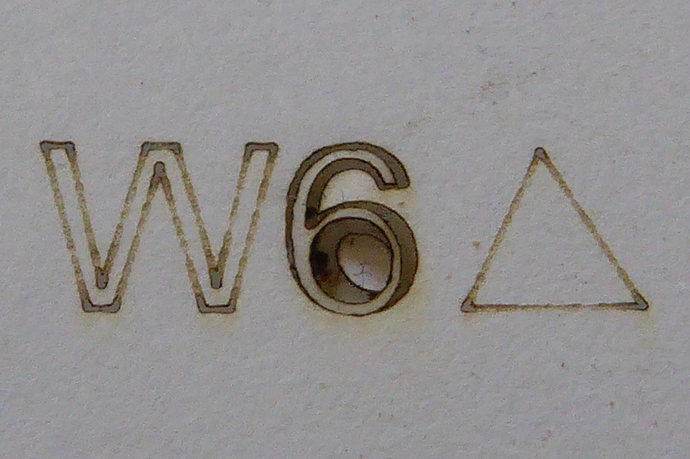

Here is an example of ‘score’ operation on foamboard which really shows the problem. I know this is not PG material and I am only using it as an example because it shows the problem better. The same thing happens on PG material.

In this example the number 6 movement was very slow in comparison to the W which is why it burnt through. Settings were Speed 500 precision power 1!

I have worked with G-code post processors (Fusion360) that implement curve smoothing and curve transformation into simple position movements (for machine that do not understand G-code arc commands). Couldn’t glowforge implement a similar post processor to stop things like this happening?

e.g.

- Simplify lines that are more precise that the machine is capable of cutting into simple XY movements that are at most the width of the laser which would ensure a minimum speed of movement and essentially join short segments into a curve. This would be based on machine resolution and cutting speed.

- remove overlaps of lines that start/end on the same point, and change direction by more than a set angle, offsetting the new start by width of laser (or more?) to stop double burn.

I ended up recreating the text as filled outlines and using ‘engrave’ instead which worked great but the problem occurs pretty much everywhere using ‘score’ or ‘cut’ on every material but is more pronounced on softer materials like card.

As another workaround I have been joining curves into one path to stop this from happening which works in some CAD programs but not all in all programs.

I see other people have reported this over a year ago:

Is there any update on a fix for this?