This is tied in with the discussion here; Problem using low power settings

Not really sure where to post this, but here goes. Anyone who was holding their breath, you may breathe, now …![]() ha ha…I needed to post this now and move on to other things.

ha ha…I needed to post this now and move on to other things.

I wanted to test on transparent film (to help my brother) and also on card stock. This is the film that I used;

Below, on the left is an engraving test. It peters out on the top right part of the circle because I didn’t have it secured to the bed well enough and the GF fan was blowing air up underneath it while engraving. Test on the right (A) is the first test for scoring. It looks good, but was too deep. It pretty much cut all the way through. With slight effort, I could push that design completely out.

Below; in sequential order, tests E & F came out very well. Scored on the surface, but not all the way through. The back of the film feels smooth to the touch.

I used my desktop computer screen set to white and turned the brightness up to take these photos. The photos do not show the whole potential for this use case. When lasering the film, I placed it on a piece of black card stock which also got ‘lased’. You can see the results of the changes in power. I labeled them to correspond.

The rest are miscellaneous on card stock;

cutting (obviously also a lesson on which fonts NOT to use! ![]() )

)

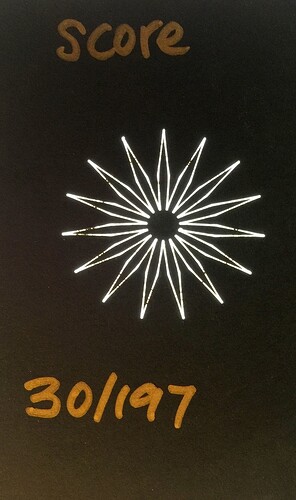

Scoring;

And last but not least, engraving;

I also engraved using LPI 225 and couldn’t tell any appreciable difference.

I think they are still tweaking the focus settings, as myself and other PRU users have experienced some very different things, but for now these worked. If someone knows a more suitable category for this post, please…feel free.