I plan on venting not just outside, but far away enough outside that I shouldn’t have to worry about any discoloration to the house around the vent. Anyone else worried about possible discoloration from vent fumes?

Oh they do got filtration systems, but they are quite expensive. Miller’s 130 fume extractor $1500, wellers WFE2ESKIT1 $1k, and many more… Not including the exclusive expensive replacement filters… I can’t find any products out there uses household hepa fillters though

Opinion: If you plan on cutting a lot of plastic, you should get the filter that is engineered to work with your GF. If you make you’re own, you could reduce flow out of the unit and A) cause extra strain on the blower motor and shorten it’s life drastically B) cause smoke/soot to accumulate on your mirror and it might ruin your head. Not to mention you could void your newly extended warranty by altering it’s normal/engineered performance.

You really need to know what you’re doing in order to successfully modify your very expensive investment without damage or shortening it’s life.

This is not a makerbot cupcake, this is a high tech precision laser cutter. If I was going to make any mods to mine, it would be long after the warranty expired and with a lot of data and monitoring.

Thank you. Would placing a filter on the outside end of the venting hose have that kind of impact on the GF? I had planned to use the GF filter for any plastics etc., but was thinking about wood, cardboard, etc. if it would affect the GF at all negatively, perhaps you are right and just go ahead and use the underneath filter for everything…

Unfortunately, any blockage on the input or output is the same strain on the blower.

I bought the filter for both home and work units. In the distant future, I was thinking about trying to build a chamber outside that the vent hose would go into with unimpeded flow in and out, but the chamber would be filled with cold water vapor. I would use a household humidifier that uses ultrasonic to create the vapor instead of heat, like this: https://www.amazon.com/PureGuardian-Ultrasonic-Humidifier-Guardian-H920BL/dp/B009COIFAC/ref=pd_lpo_121_lp_t_4?_encoding=UTF8&psc=1&refRID=55CBFXMJTJZAN0ZEMK3R

I would have to put in a check flap in the vent line or just be really religious about closing a damper in the line to avoid the vapor back-flowing into the Glowforge. Still haven’t decided if it’s worth it, and I’d still probably wait until after my warranty expires.

Maybe a boost fan to go into one a bubbler chamber, like they have for indoor dryer venting (yes, among the stupidest things in the world but sometimes better than the alternatives)

Hmm… Smoke bubbling through water. Seems like I’ve seen this before… ![]()

That was my first thought a while back, but then I remembered that I’d have to match the fan speed perfectly in order to not pull the blower blades of the GF faster than it’s motor. if you’re booster fan is too powerful, it could harm the system. if the booster is too slow, it could harm the system. so I abandoned the idea because I didn’t want to do the hard work of synchronization…cause I’m lazy  . that’s when I came up with the vapor absorption theory. I’ll have to do some tests in order to confirm it’s plausibility or usefulness.

. that’s when I came up with the vapor absorption theory. I’ll have to do some tests in order to confirm it’s plausibility or usefulness.

If I had a need for this (and maybe I will next winter, being in vermont and all) I might try to build some kind of damper/check valve/flappy bit/controlled leak just upstream of the booster, so that you you never pull a vacuum, and could leave the booster on throughout your session. Also, while I’m on the advice that’s probably replicating your early design thoughts, what about a bunch of mister nozzles like at supermarkets, rather than the cold humidifier? I don’t know whether you would get better effectiveness from droplets or from vapor that wanted to condense when it got lots of nucleation sites in it…

I started unhooking the vent hose and plugging up the hole at night. It got cold a couple days ago and temp was cold coming in.

I’m not too worried about venting outdoors. I send more smoke into the air when I have my smoker going than the Glowforge

May produce. And it seems like most of the nasties are things we shouldn’t process.

So far the vent has worked just fine. The bed stays clear. I will however try and get to examining what comes out during a print. Not easy since I am generally solo on these projects. Tomorrow I’m having some folks over though.

While the vapor can be more condensed and capture more pollutants, it is also very light and might just be carried away by the air (I don’t know what the flow rate is coming out of the machine), in that case a water mister would be better because it is heavy enough not to be completely blown out of the chamber by the exhaust. So many variables! So many questions! so little answers until we get our units!  They really need a “mind blown” emoji.

They really need a “mind blown” emoji.

this post on Reddit shows a bucket filter design

and this, at what place in the exhaust process setup is it best positioned

One key takeaway here is to avoid ducting inside the house under positive pressure. Any part of the exhaust with positive pressure will leak. If a booster fan is to be used, place it outside the living environment if possible, so that it provides suction (negative pressure) in the ducting inside the house.

Except you can’t avoid it entirely, because the GF fan is going to put at least part of the path under positive pressure. (And you don’t want any significant negative pressure on the GF fan, because you can over-rev it and badness ensues).

I’m not too worried about this, assuming a little basic tuning in place. First, because the volume isn’t that high, and second because such systems are at least a little forgiving. There’s a little hole in the flue from our furnace for the pressure check (required by code to make sure there’s sufficient draw), and once I asked our plumbing/heating/electrics guy if that hole should be plugged between measurements. He looked at me as if I were crazy, and pointed out the area of the hole versus the area of the flue…

My comment was directly mainly at the case where booster fans are being used. Yes, there is a positive pressure at the exit of the Forge, but a simple duct run to a window won’t develop significant positive pressure, and won’t leak much at all. Putting a booster fan inline near the Forge, to shoot exhaust a long distance, will end up filling the workspace with fumes, even if the duct is carefully sealed. The housings on all the booster fans I’ve experienced leak badly.

Agree.

Testing my installation of a booster I found every flange in the fan housing assembly needed to be sealed.

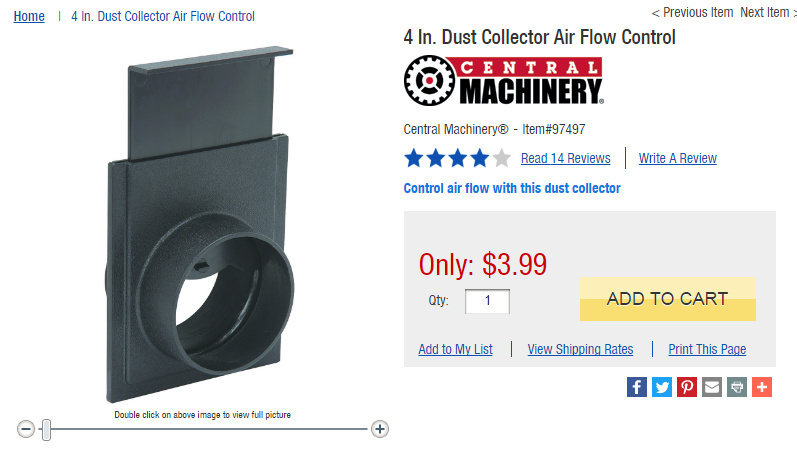

Also found the blast gate aluminum frame leaked, so I disassembled and reworked it for tight clearance and sealed the edges with silicone.

So the take-away is that if you’re not up to opening and sealing the booster fan, place it at the far end of the duct run (or outdoors if possible).

If indoors, open a little bleeder hole in the duct near the fan (on the suction side) to suck up the leaking air in the vicinity of the fan, and you should be good to go.

This is the fan I use with my garden it its a one body housing and van not leak air unless your ducking is bad. This fan is way to much for the gf, it would create to much negative pressure but can be controlled 0-10v