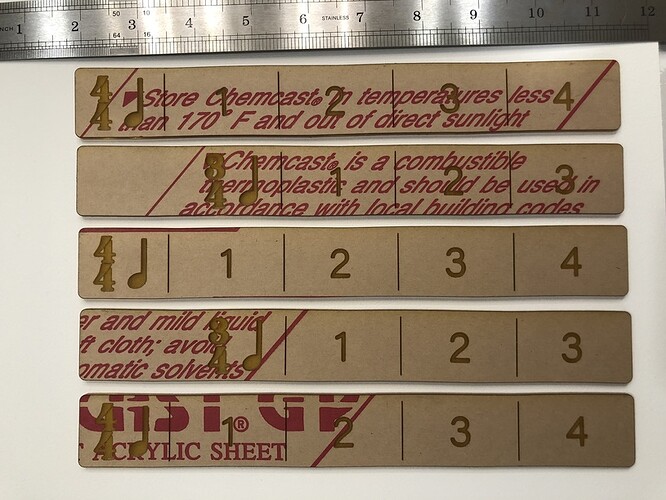

All of my long, horizontal lines have started becoming wobbly and curvy - even though they should be stick straight. I’ve gone through all of the procedures of tightening the belt on the laser arm and checking the wheels on the carriage - the belt is tight and I don’t see any obvious issues with the wheels on the carriage. When I move the print head manually across the arm horizontally, you can kind of see the wobbly motion of the print head. I swear it has to be something wrong with the carriage. Any advice? I’ve been in touch with customer service, but they’ve stopped responding to my e-mails. They keep telling me to tighten the belt, but it is as tight as it will go - I’ve checked the tension and it looks exactly like the troubleshooting videos. There has to be something else…

Check the wheels on the printer head. You may have a problem there. I think I read something like this awhile ago and one of the wheels broke

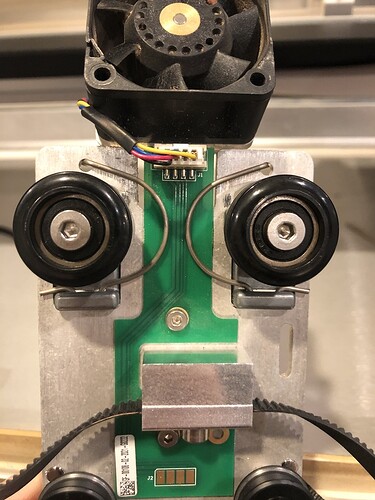

Thanks for the suggestion. I have checked the wheels under the print head and they all look good - no cracks or any indication that they have broken. The carriage wobbles as though the wheels are off balance or unlevel in some way though. I don’t see anything off though. It’s so frustrating!

It’s kind of hard to tell in this video, but you can kind of see the print head wobbling back and forth (towards the front and back of the machine) as I move it across the laser arm. It is most significant on the left side of the machine (if you’re facing the machine).

That link is not working for me…

I think I fixed the link to the video.

I think my wheels look ok, but after reading through a few other threads of users having similar issues, I’m wondering if my wheels just aren’t showing the breakage yet. Is that an absurd thought? What’s the best way to request a new gantry / carriage from Customer Support since none of the other troubleshooting techniques have resolved the issue?

The video you posted shows movement typical to a wheel that has split along its centerline. Inspect each of the wheels on the carriage plate, looking at them from the side, not from overhead as in your pictures. Cracks or splits along the centerline cause the wheel to lose retaining power as the split allows the wheel’s ‘V’ channel to open wider as pressure is applied to it against the gantry support rail. When the wheel rotates and the split portion contacts the rail, the pressure widens the wheel and the carriage plate responds to the loss of retaining power by tilting away from the affected wheel.

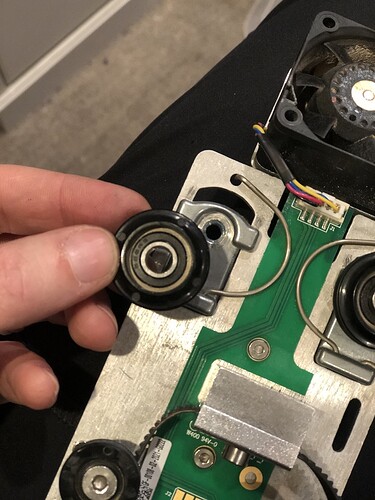

Thank you for that explanation. Could that be something that would be happening internally and not necessarily on the surface? Looking at it from the side, I don’t necessarily see any damage on the wheels, but clearly, something is wrong.

It could also be from a bearing that is sticking or has a broken race… If you grab each of the wheels attached to the carriage plate, you should not be able to rock them from side to side, try taking each one and seeing if any of them can be rocked on their posts. They should be firmly mounted to the posts on which they stand, and be able to rotate but not wobble at all.

The front two are definitely stable, the back two are definitely not. I’ll post another video. Hold on.

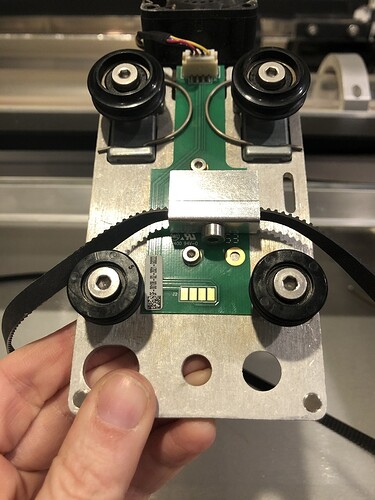

I took that left wheel off - this is what the underside looked like (and then the post), so no additional washer or anything. I also uploaded another video where my husband held the gantry steady, so it shows the movement of both wheels better (and not the springs).

By the way, I really appreciate your help. Thank you so much.

The left rear wheel looks to have a loose bearing, the rear bases move slightly because of the spring-loaded nature in which they mount to the carriage plate, but I can see the wheel itself moving more than the post to which it is mounted. It could be something as simple as a loose screw, or maybe you’re missing a washer? You may want to remove that wheel and check the bottom side of the bearing to make sure that everything is intact and that the bearing seal has not ruptured.

Luckily I am able to watch these videos on a 40" monitor. What I am seeing is that both of the bearings on the rear wheels are loose, but I’m also seeing that the posts are not secure against the sliding bases. If you look really close at this last video you can see the posts moving just slightly as you move the wheels, there is a tiny gap at the base of the post where it meets the sliding base that slides in the carriage plate. I think this is your problem, some minor play in the mounting posts and bearing wobble that’s allowing the carriage plate to wobble as it rolls along the rail.

New bearing/wheel assemblies are in order… bad news though. The rear wheels are not available separately, they are only available by ordering a replacement carriage assembly.

I’m so incredibly sorry for our delayed response. We just followed up with you via email and we’ll continue working on it there, so I’m going to close this topic.