No need to apologize - I was mostly thinking out loud and no negativity was intended. Kudos on the Q&A, BTW. You sure are good at rallying the faithful. I mean that in a positive way.

Head accurate and consistent zero position. Understood.

I can place fixture in bed (consistent and accurate). Understood.

Software that lets me numerically (x,y) position the image to cut relative to the head zero. Not answered.

I don’t want any community answers.

No, you can’t enter a numerical offset right now.

Thank you. We need to be able to locate the drawing to be cut to a software repeatable location relative to the head position.

Please add a numeric 0,0 in software interface at the cut head origin, or an alternate way to snap the drawing zero to the head zero point.

I appreciate your timely response.

If you make an SVG, can you rely on the positions in the SVG file as being repeatable with respect to the machine’s home position? Everything I’ve read leads me to think that the answer is yes, but I might be missing something.

@marmak3261 and/or @dan

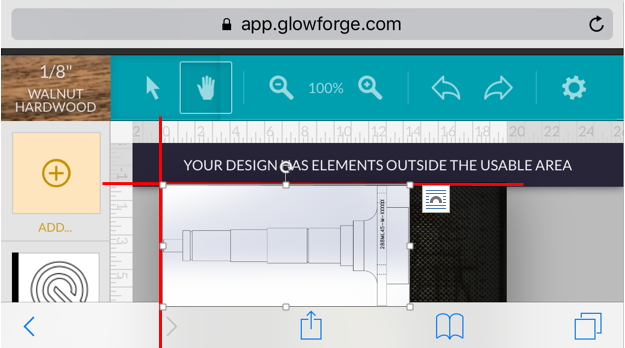

It appears from the upload of interface that marmak3261 provided that there is a scale showing the bounds of the electronic interface and cutting area inside the machine.

- is the scale shown on the interface tied to the head zero position (and consequentially to a fixed offset for the actual machine (0,0) position inside the machine… presumably (-10,5.25) from the head (0,0) based on a working area of 20x10.5 )?

- when importing the drawing file, can you “snap” the outside edges of the cut/engrave file to the 0,0 edge as shown in the interface. (see below)

This would presumably then give you precise registration of the file to a known precision location on the bed. If there is only an “optical” alignment of the drawing with lid camera or trying to look at the scales on the sides to eyeball the file alignment, there is no precision for the cut file to the part in bed.

marmak3261 was showing how the file could “hang” over the edge and show elements outside of usable area.

Good question: I have not paid attention to them since I have been zooming in and placing according to where I want it to cut on the wood. I have to say that I am really having a hard time appreciating the 0,0 X,Y issue, not having had a machine where this is critical. I know it is a critical part of most of people’s workflow.

I’m doing one off piece where I want to maximize utilization of the wood I have. I’ll keep listening and watching.

Perhaps when I line up all those almonds in a jig!

If you want I can send you my M&M engraving jig file. It holds 25 plain M&Ms for engraving. Mine is acrylic so I can wash it if needed.

Make one from the 0,0 position, do a whole bunch of other stuff and then make another from the 0,0 and see if they are the same. Or just save the original piece of acrylic, slip a piece of cardboard under it, put both in the GF against the 0,0 and see if it cuts the cardboard to match the hole that’s in the acrylic from the original jig. I can send you a piece of acrylic and chipboard for the experiment.

I think it’s useful if you cut a piece, engraved things on it, like your company logo. And then you went off, did a bunch of other random things with your 'forge, then then decided… “Ya know, instead of engraving our company logo, I want to make it an inlay.” Could you take that piece that you’d made a while back, target your existing engraving of your logo, and now make it deep enough for your inlay?

Basically, doing a second pass on the exact same spot.

Just a question. If you get no time to test/answer it, you’ll just go straight to he… I mean, you’re still awesome and it won’t affect my good thoughts of you or purchase in any way!

It sounds like a good test but as soon as you said draw something on a piece of paper, it’s a non starter. Brain too fried for this at the moment.

What I am concentrating on at the moment is understanding the interface, importing and placing the graphic files I created. I think I have that process figured out at the moment and will upload something shortly.

I hope I can address your concerns in future sessions. I have something ready to go regarding importing various file formats and how they work. But I won’t print anything till later. I have to disconnect and get to the woods.

? Ok- Nevermind then. I’ll just wait for the unit to arrive (when it decides to ship) and figure it out myself.

lol

I would hope @marmak3261 can draw that one, but I made a super-fancy and complicated pdf vector version (41.7 KB) so he don’t have to…

I’ll do my best to help. Seriously, my hands are shaking. I can’t draw right now, I’m too tired and wired!

Notebook paper isn’t laser compatible - it is prone to catching on fire. For that reason the manual recommends against using it.

Okay, but the example I suggested could be done on any medium. But it doesn’t matter.

I don’t want to cause any additional stress on @marmak3261. His comment about being burnt out is concerning.

I’ll just wait and test this stuff out on my own.

He has been enjoying his GF  while tending to people’s needs in his area while sacrificing sleep.

while tending to people’s needs in his area while sacrificing sleep.

Love his drive, but the bed really wants his company.

Thanks @marmak3261. @dan

I’m trying to distill the question to a simplified yes/no response with a “we’d love to put that in the hopper” if no.

- Does the drawing placement (relative to inch guides on top and left of interface) register (lock automatically) to the zero point.

- Does the inch guide at top and left have a locked register to the zero of the laser head

Now while I normally enjoy the banter and wisecracking of the comments from the community at large, I would prefer that Dan or marmak respond with a definitive answer.

Thanks.

Just wanted to mention…If @marmak3261 responds, you still will not have the definitive answer. It’s a Pre-Release unit running on a separate version of the software that is not fully functional yet.

Well, the statement just begs for all kinds of wisecracking responses, now doest it… ![]()

But I wouldn’t do that.