Hey All.

Whooosh, what a big thread.

I just did some registration-critical stuff yesterday with one of our older beta units. I’ll run thru what I did in case it’s useful or interesting. Note, all of the artwork in this post is me goofin’ in Photoshop.

A friend who is a founder of a smart-lighting startup here in Seattle wanted to do some user testing with some different iconography on the acrylic faceplates of their switches. He had a bunch of blank faceplates and asked if we could engrave them over lunch. I emailed a bit with his manufacturer to verify that it was acrylic, and here’s what we did.

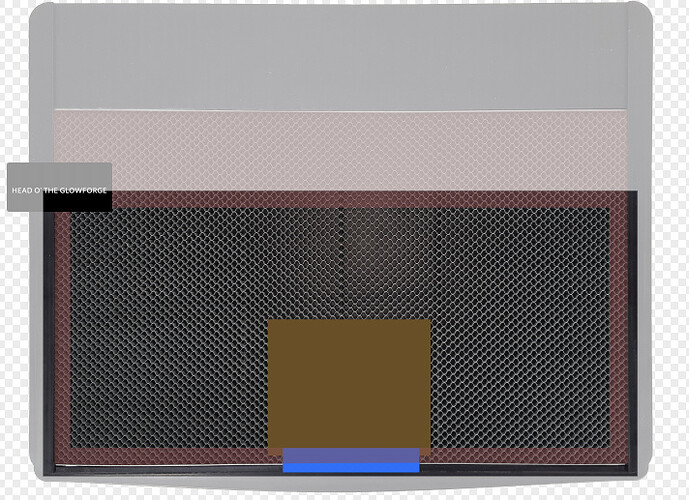

Well, first, let’s look at an empty bed (artist’s representation!)

The non-whitened area is roughly what you’d see on the screen: some of the black plastic rails (raised on the sides, NOT in front/back), the head in the upper left, and lots of honeycomb.

The reddish area are mechanical limits of the head-- you can’t print here. Of course we want to make sure MATERIAL can go here so you can cut the maximum-sized rectangle out of a larger sheet of material (i.e. the raised side plastic is wider than the mechanical limits).

My friend wanted to make certain that his test faceplates were the exact same every time. While the camera is pretty darn accurate (and getting more accurate every day!), it’s a pain in the backside to drop a faceplate on the bed and fuss with moving/rotating/etc.

So, 5 minutes later, I had a (laser cut) jig and we were off to the races (well, we had to do a few tests engraves because it wasn’t our familiar Proofgrade acrylic).

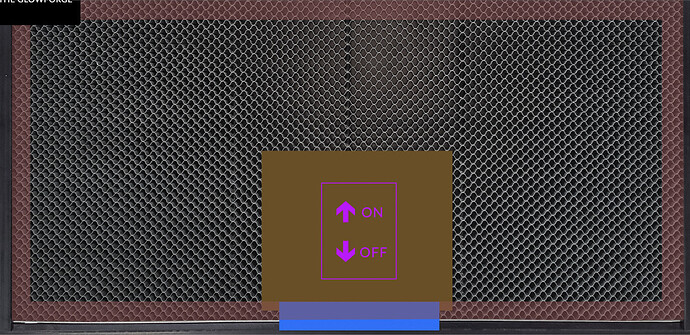

Step 1, tape some scrap cardboard to the bed so it doesn’t move (shown: blue tape!).

Looks like this:

Step 2, Upload the faceplate design to Glowforge and drag it to the cardboard. You see something like this in the UI:

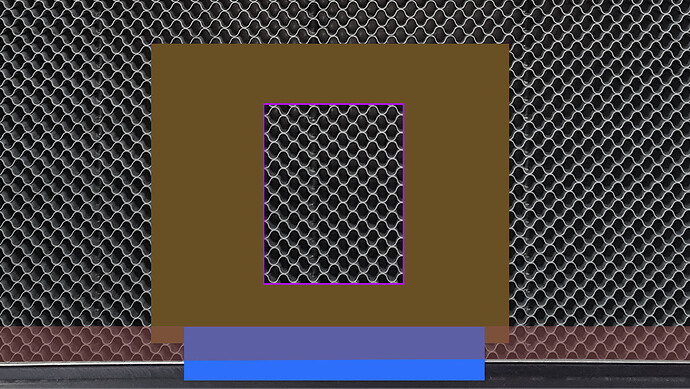

Step 3, Set the engrave part of the design to “Ignore” (i.e. it won’t print). Then cut out the outline and remove the rectangle. Now you have this:

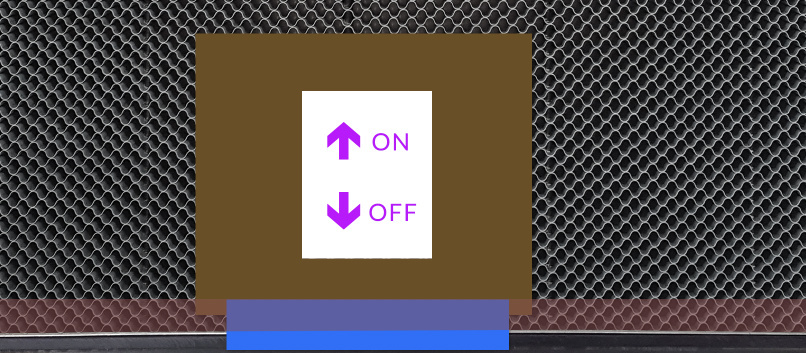

That’s a jig. Now I set the outline CUT to “ignore” and un-ignore the engrave parts of the design. I open the lid, drop in the white faceplate into the hole I cut in the cardboard, hit print. When it’s done, put in new faceplate, hit print again. Etc. Looks like this:

As long as my source artwork has the shapes in the same place, I could load any number of variants of that faceplate design and have my jig work great.

You could also make an open jig (an “L” shape for more varied-size stuff).

In practice, we’re seeing the need for this level of precision is actually really rare… It pops up when you want to cut/engrave an existing object, but obviously doesn’t matter much when you throw a raw sheet of material in the bed to cut out a fresh design. It’s certainly common enough that we want to make sure that people can get precision when they need it.

(Warning: I’m out of my element here, so Dan might correct me if I’m mistaken!)

So, could I make a permanent jig of some kind that could be used over and over again? Depends on your need for precision, I think. We derive 0,0 based the camera and the head. And we calibrate this every time you turn on your Glowforge. Given that the head and lid camera are attached to things, and that those things can change, our sense of 0,0 could change very slightly. Example: there is a tiny bit of debris in the lip of our lid that causes it to be 0.1mm higher than it used to be. 0,0 just changed.

So, by example. Say you put a piece of blue tape in a spot on your bed and on the first of every month you opened the same svg file of a tiny square and hit print (without dragging artwork around at all). Would it always cut in the exact same place? In theory, yes. In practice, it could vary fractions of a millimeter because of computer vision stuff (that we can improve). It could also vary because your lid / head relationship changes somehow.

Fairly long-winded-- I hope it’s helpful for someone.

logo) possibly aren’t as indicative of consistency in the head’s position as it may seem.

logo) possibly aren’t as indicative of consistency in the head’s position as it may seem.