Deeper down the rabbit hole. I am guessing someone would want different size holes on the second shelf.

What is working and what is not:

- Support spacing is always at one-inch increments,

- setting holes to zero will let you go freestyle with the cutouts,

- changing thickness doesn’t adjust the joint or the support half-lap

- needs an additional kerf adjustment for fine-tuning

- need to be able to adjust the distance between shelves

- need to be able to control the top and bottom shelf holes independently

- The readme page needs to explain what each variable does.

That’s enough for now and while I know that looks like a lot of gigs I think this is off to a great start!

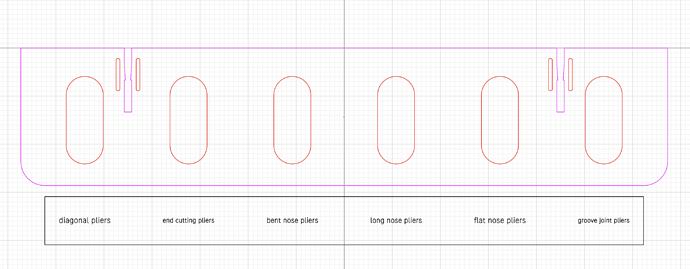

Well for the pliers, I only need one row. As you can see, I have two rows for all my little files and screwdrivers. ![]()

Thank you for the input. I was in a hurry before my trip and tried to at least capture the functionality of the original. Some of those parameters I added were placeholder, so that I wouldn’t forget when I came back.

When I make templates to sell I add a more detail into the readme’s and descriptions.

I think we should start a new thread in the forum or maybe or somewhere else. Let me know, I would like to continue working on it.

I think that is a great idea. I’d volunteer to do more than test but I haven’t figured out some of the maths in Cuttle yet. Needs to be on my to-do list as there are projects such as this one where Cuttle’s simplicity makes it better than Fusion.

I think I’d put them in there handles up. i have long needlenose like that and they are dangerous. ![]()

And trying them with handles down for a couple of days, I definitely suggest handles up!

Here is the new thread.

Thank you. Will definitely come in handy.