So when @Joe came over the other night, he left me some of the Inventibles Linoleum (laser safe) stamp blocks (2x3). He can explain more, but he had an intricate pattern that he and his friends wanted to engrave on the stamp for making play money for LARP. Since this was an unknown quantity I figured I’d have to figure out some things.

First off they are too thick to fit on the bed, as each block is almost 0.8" (~20mm) as they have a particle board backing. So had to remove the crumb tray. Before doing so I used the depth gauge of my micrometer to measure from the bottom of the machine (you can’t go through the honeycomb as there is an actual crumb tray) to the top of the grid. (A lot of people don’t realize that’s a depth gauge)

I then subtracted 2 blocks thickness from that and found that we are about 0.25" above the bed height.

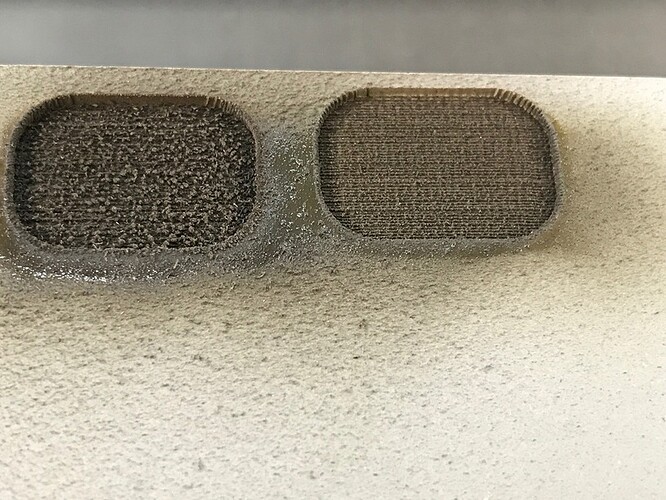

So rather than engrave intricate patterns, just made a small filled rectangle. I first tried 15/100 and that cooked into the wood and spattered a lot of ick, so moved over a smidge and tried 10/175 and it was perfect.

Now to make sure the design worked as intended I engraved onto my test piece which came out super nice:

ourNext I had the problem that the block was 3x2" but @Joe’s design was the more squareish, so laid a 3x2 black rectangle in illustrator and moved the engrave part over it (in the foreground) and using the pathfinder (boolean operations to every other human on earth) I merged them resulting in the design in a black square.

Placed it over the block and voila:

quick cleanup with a kitchen wipe and damp paper towel to remove the spatter and spectacular quality (I’ve never made a stamp before, but that was easy!)