A lathe is a very fun tool. I can and have spent many hours using mine.

A fun thing to try is, spinning metal bowls on them, a small one I made on my lathe.

Whoaaaa.

I guess it probably requires a relatively expensive chunk to start with? I suppose you could catch the shavings and reforge them…

Do you start with a flat disk and then just shape it? (How would you do metal?)

You got it Jules, it starts as a flat disk.

@jrnelson, you start with a hardwood form you turn on the lathe.

The form for the little bowl was made from Maple. Hold the form in the chuck and place a disk between the form and tail stock.

Not much metal waste at all, just a little to make it round before rolling the rim.

It does not take a big lathe to do metal spinning.

I have a used Nova DVR XP wood lathe, I bought from Northwest Washington Woodturners Club.

a short video and no it is not me, but it shows the process.

Aha! Of course I never thought about doing it like that; I naively assumed you turned a big block of metal into that.

Here’s a little project that I’ve been working on for about a year…

A friend of mine is a huge Packers fan and asked me to build her an eNable / Team UnLimbited arm. After printing the parts for two arms (one in each color), I let her pick the pieces a la Build-a-Bear. Of course this left me with a complementary set of parts, so I went ahead and built that one too.

There are a few remaining tasks – stringing the “tendons,” adding straps & padding, etc., but on Tuesday she’ll have both “home” and “away” arms!

I love it when a plan comes together!

Tech notes:

- Printed on an Ultimaker 2 using PLA+ (0.2mm layers, 50-100% infill)

- Each set of arm pieces took ~24 hours across 3 days to print

- Material cost of each device was $15 in plastic and ~$10 in fiddly bits

That’s hypnotizing!

Home and away arms? That’s fantastic!

Manual lathe. That’s what makes it so fun

Why thank you very much. That makes me feel really good

Metal. Wow very cool!!!

My is for wood only🤗

Do not know what kind of lathe you have, my lathe is a wood lathe.

Used it to turn the wood form, get some round disk and make a couple of tools and you can do that on your lathe.

Nice spinning there. Never tried it but it looks so fluid, must be fun!

Thanks for sharing with us.

Nice work Mary!

Thanks for the share!

You almost make me want to explore 3D printing… very cool!

Very nice job!! Those are amazing (Always keep extra fiddly bits in stock !)

Very interesting

I will have to look into that

I recommend a lathe wholeheartedly

Good on you for the two drill presses👍

One of those is on my list to get for my new shop someday

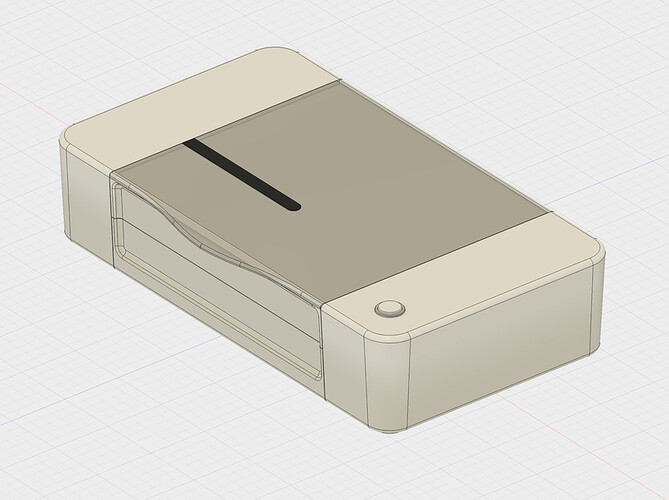

We’ve decided that we wanted our Glowforge this xmas. This is what we came up with. It’s a bit small. And the laser power is 0W. But it’s ours.

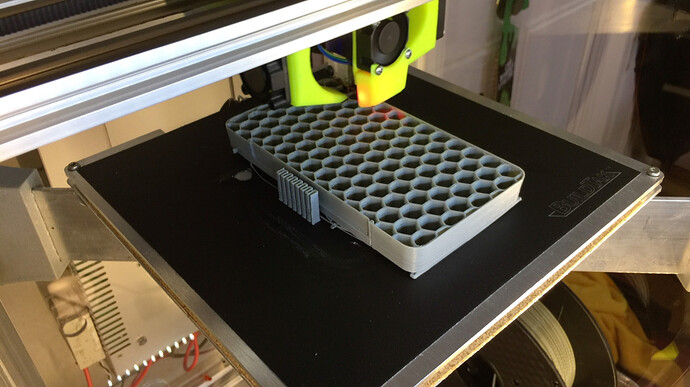

Here is the picture of the honeycomb bed.

The model I made was accurate (visually) as to the actual unit. It was not really made for 3D printing. Hence why the handle for the lid came out like crap. I may give it another shot with the proper changes to make it a look better. Kinda thought about milling out the top with acrylic and what not and use black vinyl for the features shrug

ohman, if that thing is big enough to stuff a laser-pointer down inside…