The anodized layer itself is only a molecular thin deposit on the aluminum surface and is completely vaporized during the process so even if you were doing nothing but anodized stuff you might not even be able to wipe up much if any.

Correct. It’s lost in the other residue you mentioned - the wood and acrylic dust mostly except when I do MDF because that stuff is really dirty ![]()

Even paints and glues are very thin film that you’re burning through (probably burning near totally) - way less than 1/8" or 1/4" wood or acrylic.

Yeah idk where I read it, but I definitely remember reading dangers of engraving or cutting away painted materials. Weird.

Sorry I just saw this but it seems you’ve gotten great answers. (Definitely more technical than I could explain!) As I understand it, you vaporize the coating almost entirely leaving next-to-nothing behind.

anodized aluminum and slate seem to be the “cleanest” stuff that I run. Engraving upon pre-painted plywood seems like the dirtiest (in terms of deposits inside the machine)

I’m no expert. But I do believe this is what is happening.

I believe this is true as well.

@jamesdhatch’s response sounds exactly correct to me. ![]()

So’s mine. I feel my venting is sufficient. Haven’t given it a second thought.

EDIT: I’ve just noticed that the test below had a 2mm defocus cranked into it. I’ll run another test pattern today without that.

I’ve been experimenting a bit with some black anodized aluminum. These are end panels from an aluminum enclosure we used for a test fixture. The fixtures have laser-cut acrylic panels, so we have a stack of these left over.

My results differ pretty substantially from what I’ve read in this thread. First off, even at full power, this isn’t getting close to removing all of the anodization layer. There is no exposed aluminum. I’ve made signs from these panels using an engraving bit in an Othermill, and the result is quite different.

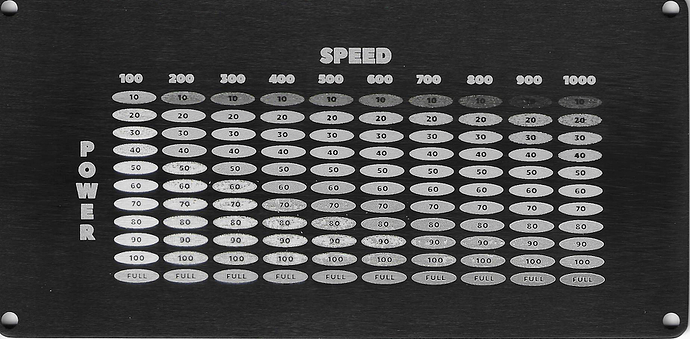

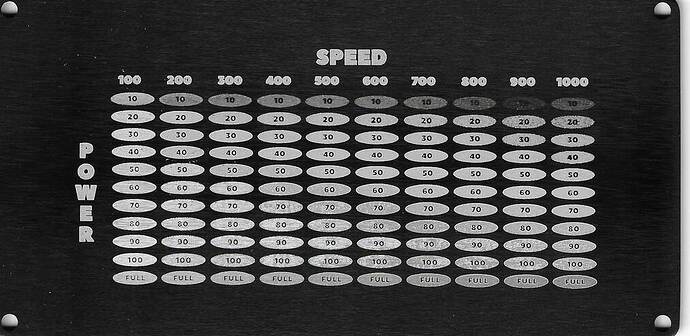

Second, there is a reason to slow down. Whatever process is happening is creating a white image in the coating. I ran a full test pattern using kirruu.berry’s file, and at high power, that white starts to get a little ‘dirty’ or burnt. At full speed, it doesn’t seem to fully cover the engrave area. I get the brightest, crispest white image along a diagonal line that runs roughly from 100/20 to 600/60.

Finally, I’m not at all sure what’s actually happening to the coating. It’s not being fully ablated, and if I drag my thumbnail across the image, it seems to hang up on the outside edge of the engraving, not the inside. This suggests that the image is actually raised. I’ll see if I can determine that better, possibly looking at it under the microscope at work. Maybe what we’re doing is boiling/burning the sealant and dyes that are in the pores of the oxide layer, causing it to expand slightly.

I re-ran the test at 450lpi and without the defocus, and the character of the engraving is similar, though obviously the settings moved a bit. (I need to recheck the 1000/10 swatch settings, that’s a bit out of place) The result is really nice, but it isn’t bare aluminum.