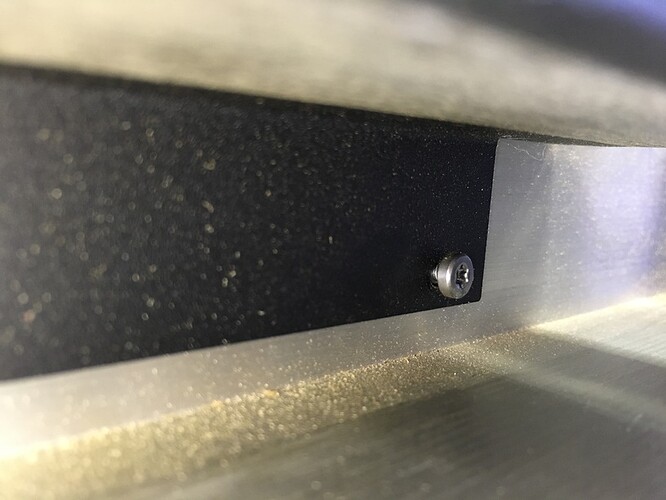

This is going to sound weird, but turn off the machine and look under the rail on the gantry that protects the head ribbon. There are a series of screws that hold it on. Look closely and see if they are all screwed in properly, especially the far right screw.

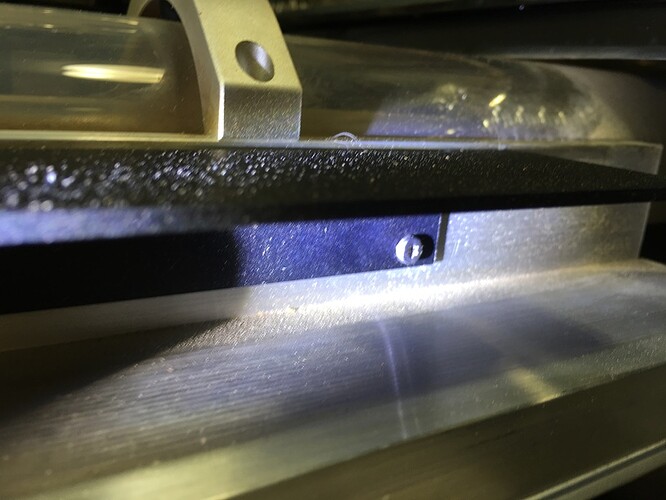

Mine was loose and seemed to be causing me trouble too. Here is a pic of mine before I tightened it:

If you look closely you can see the head isn’t firmly against the black metal, it wasn’t screwed in all the way.

If it’s loose you need a torx driver to tighten it back up. Be careful not to push on the gantry in a way that might knock it off track.

Very curious if yours is loose too, please let me know what you find.