It’s a bit scary to be honest. What happens to the dangly bits if you take a sharp corner?

The idler is held inline with the belt by side walls on the idler wheels and the linkage which doesnt allow much side to side movement, and the car doesnt lean over far enough to drag anything on the ground.

He replied, which means he hasn’t taken a sharp corner yet.

I see what you did there…

Have I really been working on this belt drive 2.5 months? Yes. Sort of. Been a hot summer so I’ve cut project time down to a real lazy 2 days/week.

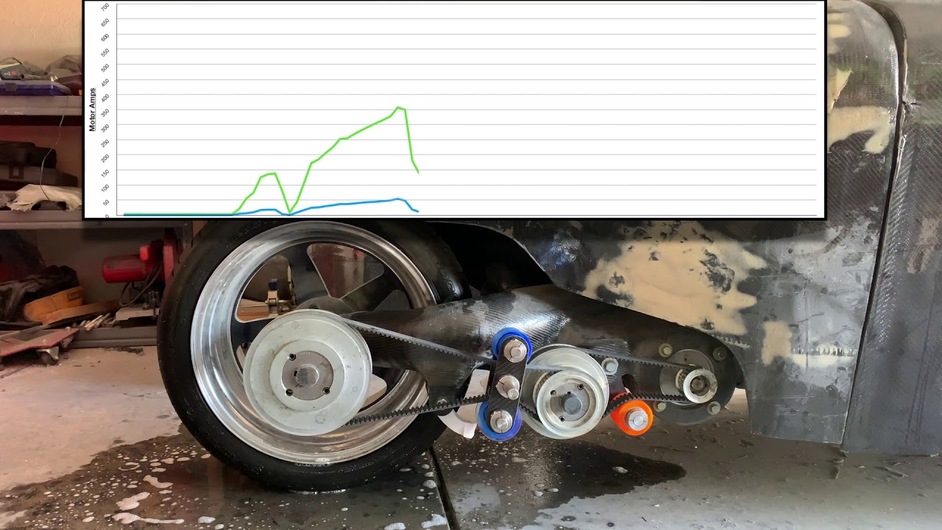

I am finding ALL the ways that won’t work. ![]()

Trying to test the tensioner under load but no dyno to use, so shy of driving it (not legal yet) my only other option is trying to spin the tire in a puddle of soapy water. ![]()

aaaaaaaaaannnnd… that didn’t happen either.

And then…

Even soapier water! And re-torqued all the pulleys so they dont spin on the shafts and try to friction weld themselves in place again.

Nada!

The animated chart I superimposed is showing the throttle input percentage in blue, and the current going to the motor in green - top of the curve is 650Amps, and it’s 3-phase power.

And success!.. well… if you consider lots of smoke and molten rubber getting flung onto your bandsaw as a success… (and I do). LOL.

Umm… electric cars are the world’s quietest burn-outs?

Saga continues!

Now that the idlers for the rear belt are sorted out, time for a test drive, sorta! My driveway is steep and is a challenge for any vehicle, so it makes a good test bed for the project car. In this test I figured I would roll the car over the edge of the incline at the top of the driveway, then reverse back up to the level section - in successive attempts, rolling further each time.

It was working pretty good until the rear wheel made it to the edge, then the gremlin jumped out of the next “weak” spot - the front idler wheel (the orange one in the video above). The mounting tabs for the front idler have slotted holes for adjusting belt tension and it’s much the same situation as it was for the rear idlers. During normal driving it’s on the slack side of the belt and will never see this much load, but when reversing up my driveway or during full torque regenerative braking it will see high loads. I am not content with the easy option of… “Just don’t do those things that break the things.” ![]()

Video of the moment of despair at 2:28 LOL! I put the video in high speed through the slow boring parts… well, the ones that are more boring than the rest.

So now onto the fix for the issue:

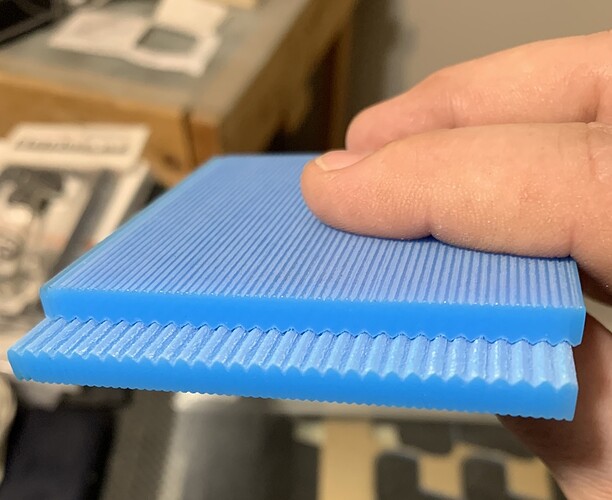

Glowforge + 3D Engrave = acrylic molds for making serrated/interlocking teeth to reduce slip in the mounting bracket. I simply filled the mold pieces with thickened/toughened epoxy then clamped them directly to part of the idler arm and waited for it to cure. The epoxy needs a few days to post-cure before I can toss it together for another test run.

The serration molds are pretty cool.

Success! Just a little pulley slipping issue easily handled with torquing some fasteners a little more.

Look.At.You!!!

I tell you what, when you get finished with this thing it’s going to be the most incredible use of the Glowforge to date.

Q: What did you make with your Glowforge?

A:

“I need a bigger wrench!”

To be fair, I am using an 8 year old torque wrench that was of suspect quality when it was new, and left it stored with the internal springs under compression the last time I used it. Should probably get another one.

Or I could just go back to cranking by hand. When I finally thought “Huh, I should check the torque specs before I take it on the road just to be safe” I found I had been using WAY more grunt by hand.

Took a couple steps back and ended up having keyways cut into the drive shafts to keep the pulleys from spinning on them. Got it back together this morning, and this afternoon after work I took it out for a quick spin!

(Been so much fun watching you build that thing! I remember when all it consisted of was a shell and a cool headlight design!)

Does this mean it’s street legal now? Pretty cool test run.

Nope, not legal yet, that’s why my test track is just 300ft of public road in front of my house.

You must and should be proud. It takes a special kind of person to take on a multi year project and stick with it.

Congratulations man! It’s got to feel great having what was once only an idea moving your behind down the street!

One of a kind.

I’m tired, Boss…

No, really… didnt sleep well at all last night, too hyped up!