Maybe I should have started with a box. ![]()

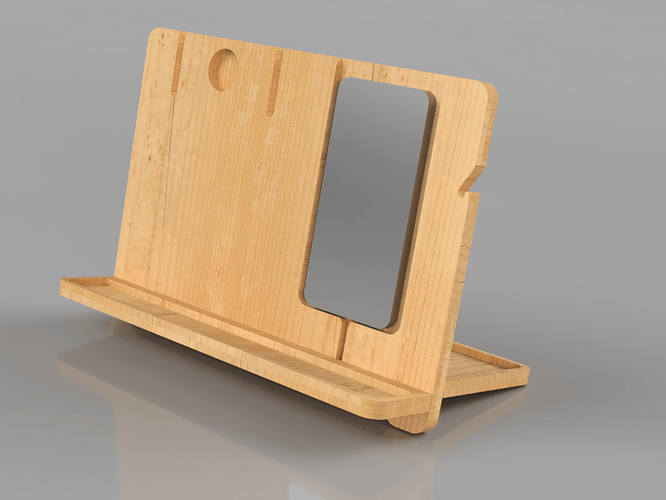

It is one of those nightstand phone caddies. I wanted one for my Apple watch and a nice area to engrave.

So one of my questions, any tips on glueing? I planning on using two sheets of 5mm birch plywood. Do I just glue and clamp? I was hoping to have four pieces but with the wire channels I might need to “split” one. Which I fear might make it more difficult to glue up.