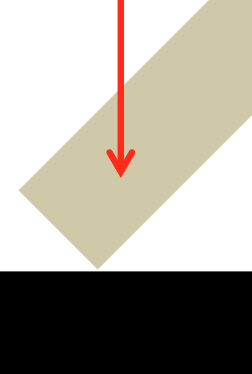

I’ve cut 45º bevels on 8" material on the crumb tray. Just takes a little planning. That’s why I love the jig above. Perfect way to get repeatable dimensions.

(Single pass with focal height set to 1/2-way thru the material. I’ve found I get much cleaner cuts in wood that way. Of course, calculating “1/2-way” in elevated, angled material takes a bit of maths!)