I guess I missed that - do pre-order owners get an extra year of warranty on their Pro models?.

True, but Glowforge was designed from the beginning to handle different types of heads. I don’t know that we know it can’t handle a CNC head. Really we don’t know much about future heads it can support.

Yeah, that was added at the last delay.

I thought the extra was 6 months extra on the warranty, taking Pro to 1.5 years.

You may be correct, look in the last delay announcement. Or I will when I get home.

I found the information from the December delay posting.

We (the founders & our lead investor, Foundry Group) have had pretty frank conversations about this. We’re all in it for the long haul. Never say never; I have a fiduciary obligation to consider any offer, and who knows what the future might hold. But we have no intentions in that direction.

The main system runs Linux, so there’s no need for a board transplant. You’d also find that the mainboard is far, far more capable than what you’d see in a typical 3rd party controller.

That’s nice to hear. (Because you could really grow this thing down the road.)

don’t hit me…

Thanks,

18 months it is. Even my iron trap mind can miss remember.

The head also attaches using magnets rather than being bolted on. Never say never but a milling head upgrade doesn’t seem like an obvious choice to me.

And imagine the mess!

True enough but the technology in CO2 lasers is pretty settled. Absent using something like unicorn tears for cooling it ought to behave more or less as other CO2 tubes and the 1st year is under warranty on their nickel.

The warranty only covers the US because shipping is not included for OS customers. Two way shipping would be $1000 at the prices GF charge plus the hassle of getting it through customs duty free twice.

The annoying thing is Dan won’t say if the tube replacement requires alignment or not. Fair enough now isn’t the time to issue detailed instructions but he must know if it needs alignment because user tube replacement was a feature that got dropped. Either they include the hardware solution for replacement without alignment or they didn’t.

All the mirrors are fixed so it should just be a matter of aligning the tube so the beam is central and exactly parallel to gantry. I don’t know if laser tubes are physically accurate enough that you can just drop a new one into the same mountings and expect it to be aligned or not but GF must know.

But it was reintroduced after much protest from the community…

Not really. It was billed as an easy user replacement. Now it is recommended as a factory replacement but they will sell the tube for those who feel competent to replace it themselves.

To be something anybody could replace I expected the tube to be in some form of cartridge, so it could come pre-aligned and just slot in. That doesn’t seem to be the case. It looks much the same as any other laser tube mounting. Not very hard to replace for a technical person like myself, but not for a lot of the target customers who are more art and craft oriented.

At the very least it involves high voltage wiring and plumbing. How easy that is depends on the connectors. Making a 20kV connection to a naked tube is not trivial. It usually has to be sealed with silicone to prevent arcing. They might ship tubes with wires attached and have an inline connector in the cable, who knows?

With the plumbing it remains to be seen how easy it is to to avoid losing coolant during the swap. Again there are fancy connectors that could make it plug and play but again, who knows?

And there is no word if alignment will be needed or any idea how that would be done if it is needed.

I personally don’t mind as long as I can buy the tube, but it was sold as easily replaceable and Dan mentioned several patents were involved in the solution. Domestic customers can always return it to the factory but OS customers that don’t feel confident to replace it themselves face massive shipping costs, risk of damage in shipping and downtime.

Being up front about what is involved would let everybody know where they stand but GF is never upfront about anything. It doesn’t need to be detailed instructions. Just a few sentences describing how the connections are made and whether alignment is needed.

The OS customers who feel that way might be better served by taking the refund before the units ship, and buying a locally sourced laser.

(I’m going to pay them the ultimate compliment of assuming that they are smart enough to make that decision for themselves.)

aaaand …I’m going to have to disagree with this statement.

Glowforge has been extremely up front about everything that this laser will and will not do. They have shown us every wart and hiccup along the way. (Painful as it must have been.)

A few folks seem to have had a hard time hearing it though, because it doesn’t match what their vision of the machine was supposed to be over a year and a half ago.

It might be time for everyone to stop and think for a bit. The units are shipping. We know what they can and can’t do. Make a decision now, whether to buy the machine that actually is, based on the current information we have. Or get your money back and go find that laser of your dreams.

The time for changing our minds about accepting one of these things is rapidly drawing to a close. The shipping notice is the last chance we get to take the refund. Once they ship it, it’s ours.

Anybody who hangs in for the machine has made a decision that they want it. If you’re not going to be happy with it when you get it, then don’t do it. It’s really as simple as that.

My take on it…(and please feel free to skip the rest…it’s probably going to be deadly dull)…

I see the potential for many little updates and upgrades to make life easier for designers down the road, but I understand that it’s going to be a while before they happen, so if that’s acceptable, it might be worth sticking it out.

This first machine was marketed to beginners, and those completely unfamiliar with lasers.

It works extremely well for that. I can attest. ![]()

And I believe it already has the ability to do most of the things the bigger, much more expensive machines do, but at the cost of a little more knowledge and effort on the part of the user. That can be improved on, but it needs to get shipped out to the target market first…beginners. Otherwise, there is no Glowforge to improve upon.

The technically savvy folk who spend so much time giving feedback to Glowforge here on the forum are incredibly important for the future development of these improvements, but Glowforge needs time to get the first unit out the door, as they designed it, not as we want it to be. That time will come later. And that machine will be better than this one, if it’s allowed to happen. We just need to give them a little breathing room.

Last thing, I promise…I was really happy to read @dan’s comment that the founders and investors have had “the discussion”, because that was the one thing I’ve been a bit uncertain about… many Startup companies do plan to sell out shortly after launch, and that can crumble a company pretty quickly.

Again, more information than he needed to share with us as customers. (But appreciated.)

So anyway, now I really am looking forward to the next phase… I hope everyone decides to hang in there for the ride. ![]()

Drop the  . @Jules has totally knocked this one out. I, too, am in it for the long haul. Looking where @dan has and hasn’t disclosed information, I’d say they releases, both good and bad, have been extremely communicative, and places where disclosure is lacking, they are most likely VERY important legal and business reasons to hold back. Just one example, because Jules said all the important stuff.

. @Jules has totally knocked this one out. I, too, am in it for the long haul. Looking where @dan has and hasn’t disclosed information, I’d say they releases, both good and bad, have been extremely communicative, and places where disclosure is lacking, they are most likely VERY important legal and business reasons to hold back. Just one example, because Jules said all the important stuff.

Replacement laser tubes. The company will be selling replacements for user replacement if the user doesn’t want to ship the laser back. The disclosure as made indicated that the fix and replacement involved several patents. Since there are people and companies that do try to sneak in and steal patent information for themselves and licensing prior to the patents’ issuance, it would be a disservice to the customers for @dan to disclose specifics before that is completed. I can totally imagine a company swooping in, stealing the  design before the patent process is completed, then rigging it to force

design before the patent process is completed, then rigging it to force  to license their own invention. Stuff like this has happened frequently in patent history, and it would be poor protection of us if dan revealed too much and allowed that to happen.

to license their own invention. Stuff like this has happened frequently in patent history, and it would be poor protection of us if dan revealed too much and allowed that to happen.

So I believe that all the reveals (the good, bad, and ugly) as well as the undisclosed information is overall done for the benefit of the customers. Remember that we are the only way that  succeeds, and @dan wants all of us to be successful and happy with our lasers, above all else.

succeeds, and @dan wants all of us to be successful and happy with our lasers, above all else.

Not 100% in agreement here. Not that he is not greatly improved vs. earlier in the process, but for this specific issue, (skipping patentable info) is this extremely, moderately, not very, not at all hard. As in do I have to have built my own 3D printer/CNC mill from parts? From a premade kit? just be a reasonably technical person capable of changing spark plugs or oil in a lawnmower or my mom?

That involves no technical info, and can give some reassurance to folks based on their experience level that they can/t do this. And is it hard (if so) due to it being a really long involved process (alignment, etc) or hard because you have to not kill yourself on a HV supply.

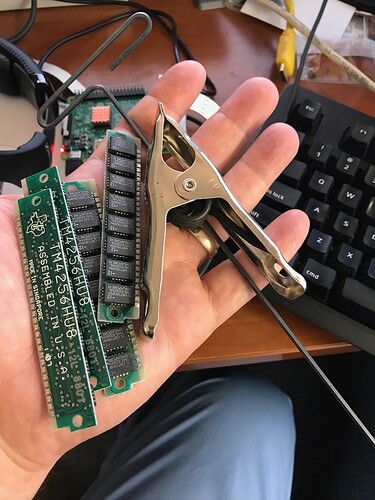

It’s like changing RAM on the mac SE-style models wasn’t hard, you just had to know how to safely be around a very high voltage CRT and how to discharge it prior to working, but way beyond most people… After that they were just SIMM slots.

There’s what you know,

what you don’t know,

and then there’s what you know you don’t know.

It’s the part you don’t know what you (should) know that kills you.