The OS customers who feel that way might be better served by taking the refund before the units ship, and buying a locally sourced laser.

(I’m going to pay them the ultimate compliment of assuming that they are smart enough to make that decision for themselves.)

aaaand …I’m going to have to disagree with this statement.

Glowforge has been extremely up front about everything that this laser will and will not do. They have shown us every wart and hiccup along the way. (Painful as it must have been.)

A few folks seem to have had a hard time hearing it though, because it doesn’t match what their vision of the machine was supposed to be over a year and a half ago.

It might be time for everyone to stop and think for a bit. The units are shipping. We know what they can and can’t do. Make a decision now, whether to buy the machine that actually is, based on the current information we have. Or get your money back and go find that laser of your dreams.

The time for changing our minds about accepting one of these things is rapidly drawing to a close. The shipping notice is the last chance we get to take the refund. Once they ship it, it’s ours.

Anybody who hangs in for the machine has made a decision that they want it. If you’re not going to be happy with it when you get it, then don’t do it. It’s really as simple as that.

My take on it…(and please feel free to skip the rest…it’s probably going to be deadly dull)…

I see the potential for many little updates and upgrades to make life easier for designers down the road, but I understand that it’s going to be a while before they happen, so if that’s acceptable, it might be worth sticking it out.

This first machine was marketed to beginners, and those completely unfamiliar with lasers.

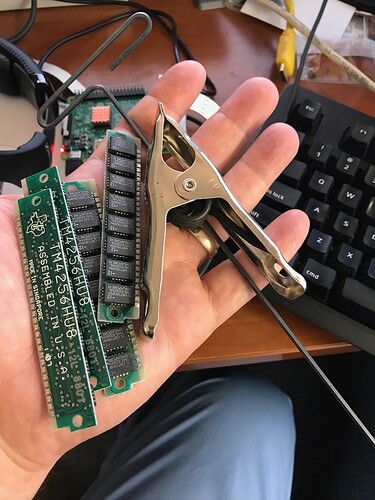

It works extremely well for that. I can attest. ![]()

And I believe it already has the ability to do most of the things the bigger, much more expensive machines do, but at the cost of a little more knowledge and effort on the part of the user. That can be improved on, but it needs to get shipped out to the target market first…beginners. Otherwise, there is no Glowforge to improve upon.

The technically savvy folk who spend so much time giving feedback to Glowforge here on the forum are incredibly important for the future development of these improvements, but Glowforge needs time to get the first unit out the door, as they designed it, not as we want it to be. That time will come later. And that machine will be better than this one, if it’s allowed to happen. We just need to give them a little breathing room.

Last thing, I promise…I was really happy to read @dan’s comment that the founders and investors have had “the discussion”, because that was the one thing I’ve been a bit uncertain about… many Startup companies do plan to sell out shortly after launch, and that can crumble a company pretty quickly.

Again, more information than he needed to share with us as customers. (But appreciated.)

So anyway, now I really am looking forward to the next phase… I hope everyone decides to hang in there for the ride. ![]()

.

.  design before the patent process is completed, then rigging it to force

design before the patent process is completed, then rigging it to force