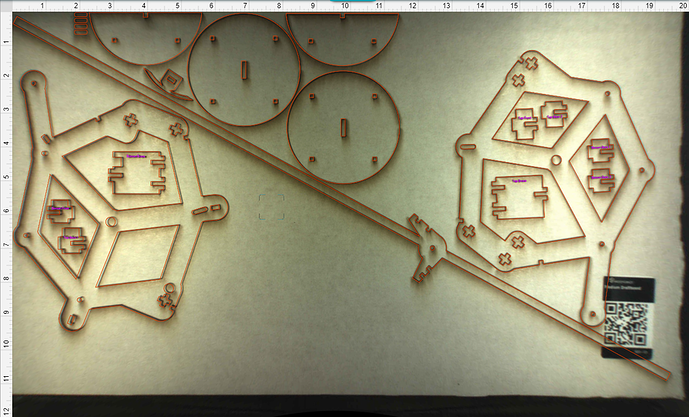

Dang, that’s a lot of work!

So… I am testing my clock in our guest bathroom. Tonight one of my sons used it to take a shower, which caused a lot of steam and humidity to form in the air. The clock almost stopped immediately.

I assume it because this escapement is still made from draftboard, and the added humidity increases the friction between the two draftboard pieces.

I will have to test this again once I have the new acrylic escapement.

Is it possible that the thicker air is just to much for the pendulum swing? I am hoping it is the friction issue and not a swing issue…

Really nice job nesting all the parts. I like the escapement too.

Would the frame stiffen up enough if you doubled it up? Or even 3 layers?

I “think” the issue is actually with the braces that hold the two frame pieces together. There wasn’t enough support to effectively hold the weight and keep the frame square.

I “think” I have addressed these issues.

The escapement really does appear to perform much better as acrylic also, so I will likely modify the SVGs so there is one for all the pieces that really should be acrylic.

Thicker air is nowhere near the problem of thicker draftboard. If you used Baltic Birch there would still be swelling, but it will shrink back. With MDF each bit swells but if it shrinks the center to center I suspect would not change back.

Well, I cannot say what stopped the clock (because I still do not know.) But, once I got it running again last night, it ran all night! New record of 8 hours and it is still running (of course it thinks it ran 12 hours… still need to address that.)

Well, the clock finally stopped again, setting the record at 16 and a half hours of run time.

I plan to attempt to adjust the pendulum today and maybe swap out for an acrylic escapement.

Edit: Well… adding weight to the pendulum did not work. The added mass was to much for the torque on the gear-train and it cannot keep the pendulum swinging. So I will need to extend the pendulum without adding mass.

I could be wrong but wont changing the distance of the weight from the center change the speed of the pendulum?

These bowling balls are all the same weight but different lengths of cord…

Edit, I reread what you said, we’re on same wavelength I just misunderstood what you wrote.

If you ever decide to switch to fishing line, monofilament is stretchy and will remember its shape after a while. Braided fishing line is stronger for any given diameter, does not really stretch and doesn’t remember it’s shape. No idea which would be better for a clock.

Also, you can trim monofilament with your teeth whereas braided requires a scissors or knife. Probably not relevant for a clock.

If you want to try it without having to go buy any, I’ve got a spool of 50lb “ez-braid spiderwire”.

Very very strong stuff that is.

Thanks for the offer, but I think I am going to stick with the nylon cord for now. If I wind it properly it doesn’t have any issues.

Finding odds and ends at Skycraft I bought two spools of dacron lacing that is small flat and crazy strong for a couple dollars each. Trying to find the same by Google I am seeing over a hundred dollars a spool for what might be the same stuff. They seemed to have tons of it then so probably have it now, but you never know for sure.

Anyway, I found this that is round and not flat …

https://www.joom.com/en/products/1491915575615069651-140-1-582-1487216944

This looks similar to what I have not at a crazy price…

In anycase I use it for all sorts of stuff.

Several lifetimes ago…I worked in a store called The House of Clocks. They had a novelty clock they sold, telling people it did not keep time, some what of an archaic design and more for looks. A customer bought on with that understanding and we gave it no further thought until he showed back up 6 months later to let us know, it took him that long but he kept tinkering with the pendulum weight sliding it up and down in minute increments until he actually got it yo keep accurate time.

My wife bought an antique grandmother clock. The housing is over 200 years old, The clock mechanism is over 100 years old. It took a bit of fiddling to get the pendulum length right but once I did, it keeps remarkably good time or at least it does it better than I do at keeping it wound. (i.e. far more error from my letting it stop vs it not doing the job).

I am a little confused today… yesterday, I installed the acrylic escapement (which should be better and run smoother), but I haven’t been able to get the clock to run for more than 5-10 minutes since then.

I don’t know if the frame shifted again in the process of installing it (I haven’t made the new frame yet) and that caused the clock to have more friction, or if the acrylic escapement has a different issue?

I am re-installing the old Draftboard escapement just to test, but my assumptions are that this is a frame issue and I need to make the new one.

Well, the old escapement was just as bad (relieved) . I was afraid everything I learned about the acrylic escapement was wrong for a moment there…

So, more clock surgery today since I have the day off.

Here is the longest single-piece pendulum rod I can cut (since I don’t have a Pro), so I hope it is long enough. Otherwise, I will need to get creative again… (But, if it doesn’t work, I already have a few ideas.)

Hopefully, I can get the clock running again today (and keep it running).

I will eventually use ply for the frame… so maybe I should start heading that way since the draftboard has been giving me issues…

That was how I was doing the pendulum before I used the compound method. It was causing issues at the time. I didn’t realize it had to much mass. When I reduced the mass with the compound pendulum, my clock started running for longer periods of time, but was to fast.

Now I am trying to get the length and reduced mass… so we will see.