@evansd2 I mixed the iron oxide with water and applied the resulting mixture like paint:

It will eventually dry out enough to start flaking off, but it takes a while–I painted my test tiles in the afternoon and was putting them in and out of the laser into the evening, and the iron was still affixed firmly enough that the fans weren’t going to move it.

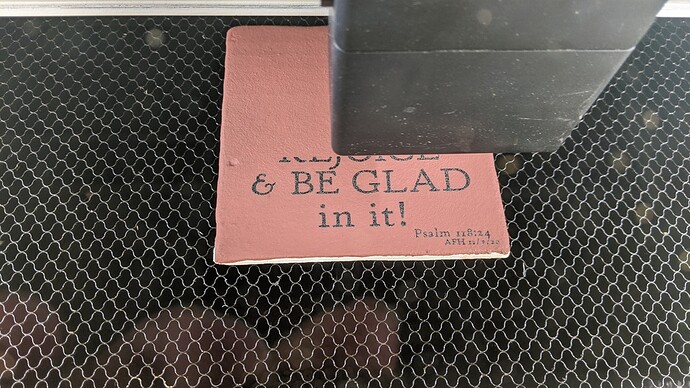

The fuse itself produces no detectable fumes–I forgot to turn on the air filter for one pass and still couldn’t see/smell anything. Not that I recommend leaving the fans off; it’s not necessary with the wet mix. Here it is in the laser with the fans on:

I would definitely not recommend trying to use the dry powder with the fans turned down or even off. Iron oxide is more “maybe don’t huff it” than “evacuate the building” in terms of potential toxicity, but it’s still a very fine powder that can contain free silica, aka tiny lung knives. It can damage your lungs, especially over time. For iron oxide, mixing with water will mostly neutralize the risk, but some of the other metals Clark mentions require further precautions.

Applying the wet mix

For unglazed surfaces, the mixture can be pretty thin–the consistency of whole milk. I found that glazed surfaces need a thicker mix to adhere to the tile–closer to acrylic paint or chalk paint. To get it to stick to the glaze, I needed to roll on 3-4 coats with light pressure, letting each coat dry for a few minutes before applying the next. The first coat gave me really splotchy coverage but helped subsequent coats to stick. I may experiment in future with adding a brushing medium (a thickener used in ceramic glazes) to improve adhesion.

It will adhere to glaze more easily with a brush than a roller. Clark reported that the ridges left behind by the brush affected her results, but I found that with the laser focused properly, this wasn’t a concern even with pretty deep ridges (I initially had it set to a material thickness of 1/8" because I had a brainfart, but when I set it it 1/4", which is the actual rough depth of my tiles, it fused through the ridges with no problems).

Clark reports that her mixture flaked/scraped off quickly, but I think she was using alcohol. Using water, I found that once dry, it’d mostly lift if rubbed with a finger or towel, but came off cleanly from glazed surfaces with a damp sponge. It leaves a light stain on unglazed surfaces (of tile; a dark stain on unglazed surface of everything else; my workshop looked like a crime scene. Will definitely do more prep next time).

Cleaning up

The unfused iron is reusable, which is another advantage of a wet mix–less loss. I squeezed the sponge out into a tupperware, and dumped my leftover mix in same. It can be stored indefinitely. If it dries out, just add more water. ![]() .

.

Protect your pipes

There are lots of ceramics ingredients that can damage plumbing and I’m not sure if this is one of them. I have a bottle trap on my lab sink so I don’t get in trouble with the building owner. But you can also just rinse your tools etc into a bowl or bucket and leave it for a day or so. The iron will sink to the bottom. You can pour the water off the top, then add the iron to your container for reuse.