Here’s what I did:

After reading a lot of great advice about how to vent Hiakari, my issue was that I wanted to be able to fully winterize when I’m not using the forge for a while. IT COULD HAPPEN…

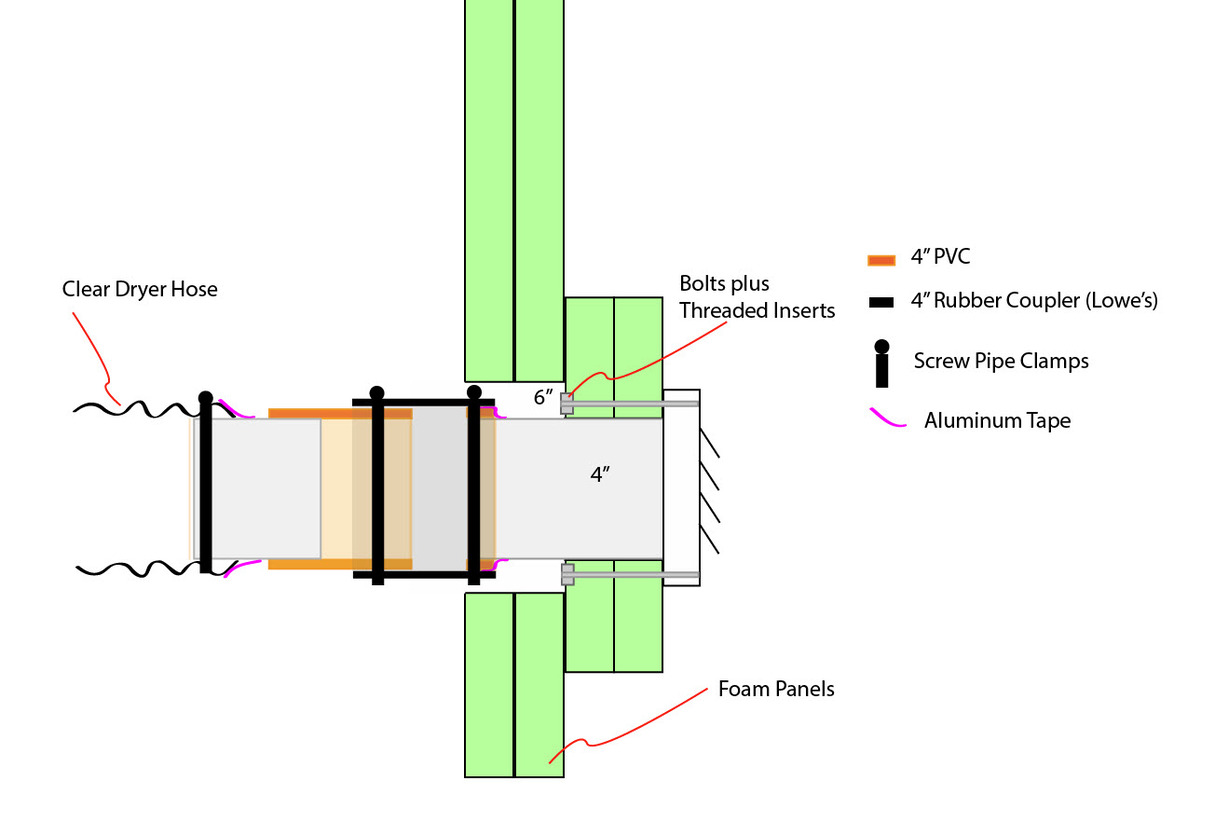

I have double hung windows and I’m not ready to cut holes through my wall yet. So I went with the idea of using foam sheets cut to fit below my outer window and double-layered and foil taped to seal. Then I cut a 6” hole in those foam sheets. I added two more squares of foam panel to cover the 6” hole with some margin. The exterior foam has a 4” hole with the louvered dryer vent and a 4” diameter aluminum tube that I cut off even with the interior sliding window. With this arrangement, I can still close and seal the interior window for weather and security.

On the inside, I put a short section of PVC pipe with ID 4” and taped it over the aluminum pipe to the vent. This makes the diameter proper for my internal connection. I got a 4" rubber seal with screw pipe clamps at Lowe’s. This is the part that I unscrew to remove from the window and shut the window.

In the end of the hose, I have another short length of aluminum tube pipe clamped and taped and then the tube inserted in another 4" PVC pipe. The aluminum tube to PVC connection is so tight, I didn’t tape it, but I might.

The 4" PVC pipe sections are to adapt the aluminum tubing to the rubber coupler ID.

Works great for me and no leaks. With this setup, I can see that the louvers open and I can see contaminant buildup.