A great first-time engrave. I love your wife’s artwork…and I also loved the music video. You are far more limber than I, being able to get down that low on the floor…especially the whole time holding and playing that bass…and then actually being able to get back UP! Good work on all fronts!

It’s not just a case of different backgrounds here though, Philip’s test machine has one of the wonky tubes, so he’s unfortunately being forced to do it that way, by adjusting the power and speed settings.

I haven’t had to adjust any power or speed settings. The Glowforge is interpreting the file and changing whatever is needed (looks like a combination of power and/or speed and depth/lpi) to get different shades.

I really do think all we’ll eventually need to do is a few curves adjustments in Photoshop or GIMP to get some really great results. ![]()

(It’s very squee!)

Having said that…they are obviously still adjusting the ranges and fine tuning them. The new tubes are very powerful and it’s currently fairly close to charring the deeper ends of the spectrum. Once they have those set though, it should be “Katy, bar the door!”

Might be wrong. Time will tell.

![]()

Yep, the tubes are cutting and engraving well. I ordered a Pro mostly because I was worried about potential cooling issues. Clearly that hasn’t been a problem and can’t now figure out why I needed the extra 5 watts of power. But I do have one size application in mind that only the Pro could satisfy.

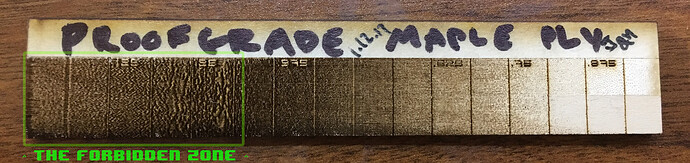

Its not that so much as the color range of the input file. I cant engrave anything in the lower 1/3 of the grayscale tonal range without getting distortions. That means I have to pre-process all of my images to move all blacks up to a value of 85 out of 255, and everything between scaled up proportionately.

You can see on this piece where the visible distortion begins on the low end. Everything to the right is great, but the left 1/3 is unusable land. I still use the default proofgrade settings and things come out great. I just have to make sure to apply my level scaling profile before engraving =).

Soon my friend, …soon. (We’ll all be blowin’ and goin’).

“glowin”

I wasn’t touching that:grinning: Jules has admitted to a wild side

True dat!

Hmmm that forbidden zone looks like my marshmallows on my last camping trip…

For the moment, the answer is “don’t worry too much since there’s a lot of changes coming to this part of the software”. ![]()

The software is optimized for pure black-and-white. The best way to scan a greyscale or color image is to start with your phone or a scanner.

An interesting side effect of the physics of the laser system (any laser system, not just Glowforge) is that speeding up the head reduces the maximum resolution. Something to keep in mind as you experiment.

an interesting consideration; i guess that’s true for various reasons for lots of subjects besides the laser. i can imagine cv issues, too, though maybe not at these speeds.

Is this something we can get a chart of from you guys? Id really like to know when Im upping my resolution in vain =P

Thanks for this useful little tidbit. This is the kinda little stuff I like to learn while preparing for my very own GF. (Not that I really AM doing any preparations. I’m a procrastinator and I’m preparing to prepare for it, sorta.)

Congratulations. I’m loving all these new pre-releases out in the wild… getting closer to real shipping dates I hope.

Also hoping the software is closer to full functionality and release…

Horizontal resolution is always “as high as we can”, limited by the head speed + source bitmap.

Any data we share now will be obsolete soon, so no, at least not right now.

Do you mean head speed relative to the frequency response of the laser PSU? I don’t see how speed alone relates to resolution.

I’m assuming that’s what he means as well. Just for ballpark, at 10 inches per second, 1000 ppi along the direction of travel means 100 microseconds per dot, which is 10KHz. But to get pretty dots of controllable power without smear at that resolution you’re talking about 100KHz or better at high voltage and power.

It’s the entire laser/PSU+everything else system, not just the PSU.

Yes, from a quick Google, Co2 laser tubes seem to quote <= 1ms response time, which would certainly limit engraving speed.

It is so totally unimportant should my Topics or Posts get more than a couple “Likes”. Heck, I’m very reserved when it comes to giving them out. But my OCD-lite tendencies are showing. The original post is stuck at 99. It’s too close to the big 100. I don’t know whether to ask a half dozen folks to unlike this topic or to beg for 2 more. Either way works.