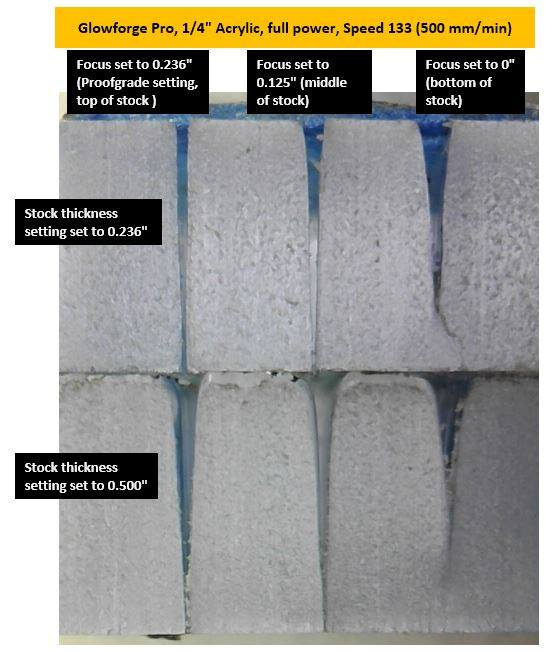

This pic illustrates perfectly what is happening when the machine cuts, but also why you might have difficulty with thicker material. The beam has to be focused to vaporize the material, and can only be effective across a narrow range. Even if the first pass makes it halfway through the material, your second pass at a lower focus is going to have some of the beam power blocked/absorbed by the sides of the narrower channel above.

It can be done, but all that absorbed power creates heat, which will melt the material, further interfering with the ability to cut cleanly below - and also increasing the risk of fire.