Not to be “That Leaf Guy” but I had another idea.

I took the black and white leaf back into Photoshop. I ran it through 5 layers of different blurs to get this.

3D ENGRAVE!!!

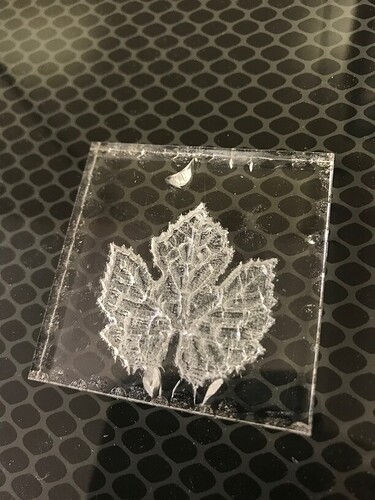

I did a first 3D engrave on unmasked 1/4" extruded acrylic. It left a residue that I tried removing with alcohol and the part crazed and cracked like crazy. Plus the impression was pretty rough.

I read a post about a second de-focused pass to polish a 3D engrave

So I redid the job with a second pass de-focused to .01. Didn’t use alcohol on the residue but did a light sanding to make it pretty for all you fine people. I also sanded a Popsicle stick to a point.

Then I stuck the paper leaf into the 3D engraving and burnished it with the wood stick.

This is what I got.