I was only looking at the ratings. The one I have is rated at 190 CFM and it is not enough when engraving oak for example, but run with the exhaust fan they are cleaner than either alone.

CFM ratings can be tricky. I would probably take a 190 CFM fan that runs at a higher static pressure over one that’s 300 CFM at a lower static pressure. Both fans would be seriously affected by resistance in the airflow path but the higher static pressure fan will be less so.

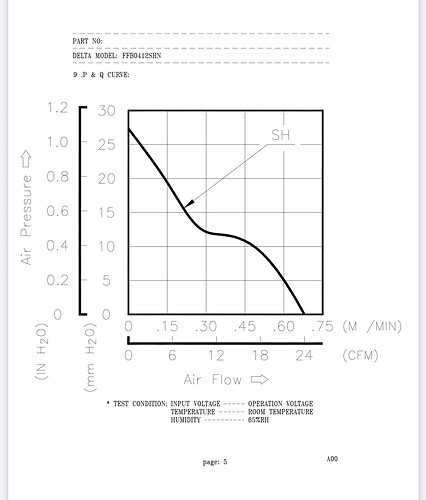

You have to look at the power curve for the particular fan to figure out what actual airflow you’ll get at different loads. I got into this a bit in the vacuum tray thread but the math gets complicated pretty quickly, and we have very little insight into the actual dynamics of airflow inside the Glowforge. You would need to measure the pressure drop across your fan to figure out what actual airflow you’re getting.

For example I feel like my external S6 fan doesn’t work as well as the internal fan by itself. I think this is because the internal fan leaves so much resistance that the S6 can’t really compensate, especially considering that the entrance and exit are only 4 inches instead of the six. I would imagine that if I were to remove my internal fan that I would get a performance increase, but since I have a pro the heat sink already causes a serious amount of resistance so I’m not sure how much of a gain it would be.

Also because it is a pro removing that fan is significantly more difficult. It just isn’t worth it to me. If I’m doing anything that’s particularly smoky I run both fans, and I do think that that’s an improvement over just the internal fan.

More info about fan specs:

Sample graph of a fan pressure/airflow curve

It’s a little tricky to read that graph but you can see the airflow decreases greatly with even small increases in static pressure. Almost every fan (at least every fan that I’ve looked at) has a graph that looks like this with a sweet spot “saddle point”.

Somebody who’s got more time and experience than I do should probably try to go quantify this for the various Glowforge models. It would be really interesting information.

I geeked out on fan performance as well for a while. I posted a lot of my findings here. The net is, when my internal failed, I removed it and cut away the grate to leave just a big hole. And (again) the $50 6" duct fan I got worked far better alone than the combination of the internal fan and a 4" duct fan. When I get another place to live, I plan to replicate that same setup - remove the internal fan and cut away the grate, and buy another 6" fan. It was virtually silent. I would also leave the lid ajar and leave it running it to draw air thru the house when the weather was suitable…

As noted In took a much more practical approach. My exhaust fan broke and I got the 190 CFM to work til I could replace the machine. It worked for most but not all cases. The exhaust fan spun easily, so I doubt it was worse than the rest of the exhaust. When I got the new machine, it worked better with both, so now the 190 runs 24/7, and the rest when in use.

same here. 6 inch alone, works very well and so much less noise.

Just a note that a freewheeling propeller on an aircraft presents as much drag as a disc of the same swept area. The fact that a brushless fan of the type found in our machines actually offers a little resistance due to how they are constructed (basic stepper motors) means they allow a little more air to flow than if they were truly freewheeling, but they still present a huge barrier.

This is why turbine-powered aircraft always have the ability to feather the prop blades - present an edge-on profile which does not cause them to rotate, hence reducing drag to its minimum. A typical piston engine will offer enough resistance to prevent the prop from rotating.

I think the nature of the shape of the two propellers would make a huge difference in resistance as mearly blowing on the one would get it spinning but not so the aircraft one,

It’s complicated, and blade shape does make some difference but the basic gist is that as the fan spins up you’re increasing the wind speed across the blade, ergo you get larger drag.

This is true of every blade shape as far as I can tell. Add to that the fact that there is some internal resistance on the motor, and the risk of reverse driving a voltage in the motor, I think you’re almost certainly better off not rotating.

Besides we’re dealing with the first law of thermodynamics here. There’s no free lunch. You’re spending energy to spin the propeller no matter what you do.

Although it’s technically possible to generate enough back-EMF voltage to damage the drive circuit (which is built-in to the motor itself), I’ve never heard of it happening - and I don’t mean just with the fan(s) in our machine. That type of fan is so ubiquitous, the drive MOSFETs are produced in such vast quantities that they can be fairly robust for no additional cost. The one in our machine is of particular high quality, and unusually expensive.

With all that said, the key here is keeping the machine as clean as possible, and an unpowered fan is going to reduce airflow, period. I do so wish they’d make it simpler to remove on the Pro, but once again, it was not designed to be a robust machine for commercial use and user-modification.

It would be nice to get actual data, but just moving with my hand is not detectable pressure, and no changes as you get with older design motors.

Here’s one that explains it pretty clearly:

A windmilling propeller creates much more drag, by an order of magnitude at least. The obvious example is an autogyro or helicopter in autorotation, which drops like a stone if the rotor stopped.

Drag is a function of blade area for a stopped rotor and a function of disc area for a windmilling one. The difference is most pronounced for large rotors with few blades and almost nonexistent for turbofans. This answer gives some numbers:

If we compute the lift component per area of a vertically autorotating rotor, it is comparable to a coefficient of 1.1 to 1.2 referenced to the rotor area. According to this source, a flat plate has a drag coefficient of 1.28 and a parachute has one of 1.4. So in vertical descent, the auto-rotating rotor is almost as good as a parachute of the same area.

I would think that an auto-rotating rotor like a helicopter would have a slight upward vector.