Yes. Yes… so many uses. Want!

Exactly! Prototyping would be so much easier. Double-sided pawn standups could easily have custom cutouts and would look amazing.

very cool!!

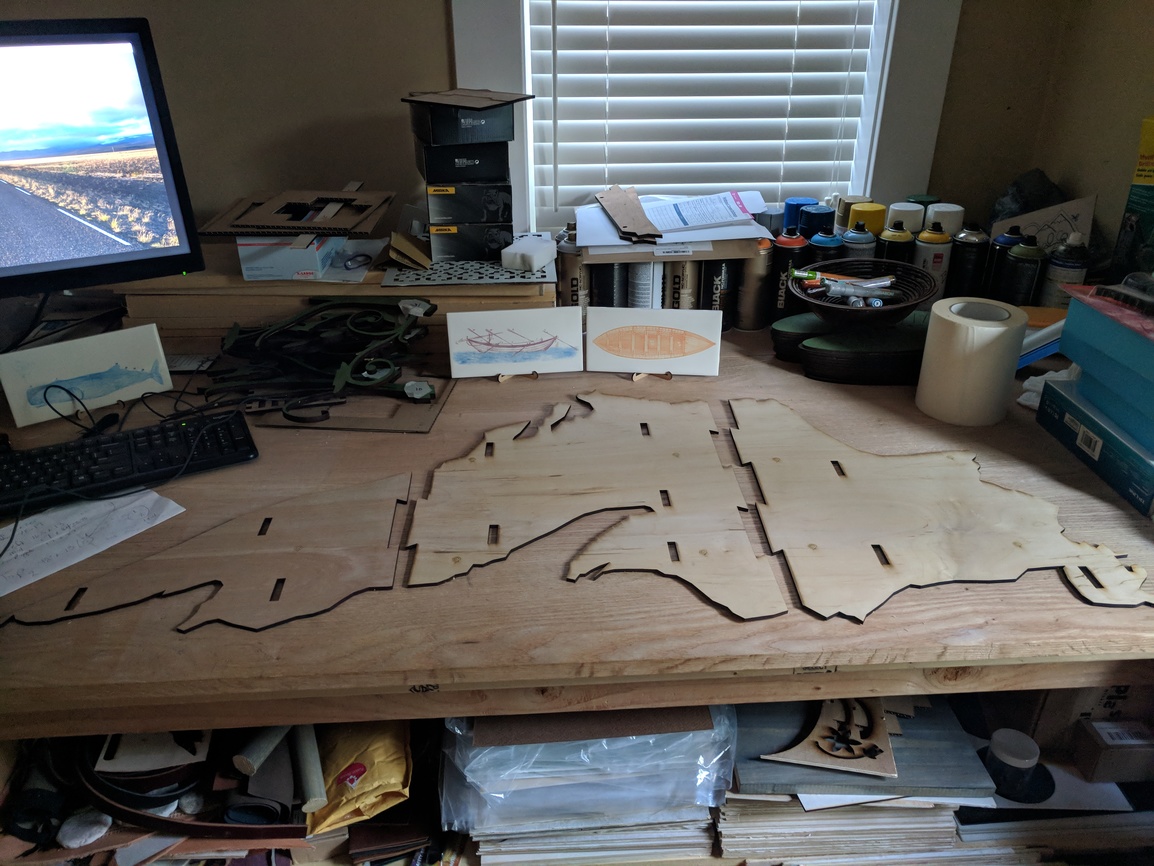

The reason we bought the Pro was the passthrough so we could cut pieces that were too large for the bed. I found the passthrough was useless for this purpose because of the inability to align subsequent cuts. I tried cutting alignment guides secured to the crumb tray plus matching cuts on the material so the material could be precisely positioned, but that didn’t work. So I had to give up on cutting large pieces and splice them together from smaller ones instead.

I hope Snapmark finally makes it possible to effectively use the passthrough. This is a capability Pro owners were promised would be coming. If it costs extra for the Pro machines, that would be a black mark for Glowforge. If the passthrough is never capable of using sequential cuts to make large pieces, that will be a huge strike against Glowforge.

It does.

You can see the snapmarks I used for aligning it as each of the three pieces went through the machine. As this is the middle of three layers that will be glued together I didn’t care that the snapmarks were on the pieces I am going to use. For the top layer the snapmarks are outside the used piece. The top & bottom layers are cut the opposite way and are 47 inches long. That’s 5 operations. I don’t have pictures of them.

As Dan said snapmarks are an intermediate point to true pass through functionality. I’ve been in R&D long enough not to count my products before they’re launched, but they are still sticking to their original goal. Until then there are snapmarks.

There’s also a number of other ways to index the project as well. It’s a common problem for CNC users. There are a bunch of tutorials here on how to get very precise alignment (within a kerf width) but they may be beyond some user’s abilities - Snapmarks should help them if they were unable to make the other indexing strategies work for them and gets even better alignment results.

Can’t wait to see this show up on my GF.

It would make so many of my projects easier, and use the pass through with better results.

I don’t want to dump on this news, because registration is great. The news of an additional cost on a $2.5K+ machine is less exciting.

I’m not sure how accurate, repeatable alignment would be a paid feature as I always thought that was one of the features we were promised (on all machines). Maybe I’m mistaken?

You’re absolutely right. For the most part, the red dot is a workaround for having it do it correctly automatically. The exception might be when you put material in to cut a second time (like cut, paint, cut again), where a red alignment dot would prove it’s doing it right. So it’s not a mark that’s just in the design file, but a mark that is made by the GF in an area that’s going to be cut away later and can be used for alignment.

When I first heard about the head camera, my expectation was that the Glowforge was going to move the head around to take pictures at various places and then combine them, like a stitched-together panorama, to get an overall bed image. And the GF could pick locations to photograph based on your design (e.g., get all the corners). It would take longer than the single centered lens but it would be far more accurate.

I thought that was a brilliant idea. Alas, they didn’t do it and it appears they’re still not doing it.

Either of those methods would be excellent.

It will make my life much easier for my longboard cutting projects. I currently can’t do them in the glowforge, precisely because I can’t use or align multiple ops in the Passthrough port easily.

Hope I can get to use it!

I was just thinking the other day, wouldn’t it be nice if there was something similar setup in the interface for snapping.

This sounds amazing, this would save me so much time when doing nun coasters. Can’t wait.

When I first read about this I was too busy lasering all the things to care too much. But now that I’ve re-visited, man…I REALLY hope I see that magnet appear in my UI!

Isn’t that the approach of how the MUSE is doing it and last I saw it looked horrible and was far less accurate? Maybe it just needs more implementation or thought about how to get it done.

I agree with other users. This should be available to all users who purchased before this was rolled out. Even if we have to purchase as a software update. Basic or pro… Who cares. If you push it to Basic users to use, then take it away and not even offer it to us? Especially those of us that waited over 2 years when new folks have to wait 2 weeks. I have faith that Glowforge will do right by all of us that stood by this effort for YEARS as deadlines were missed over and over. At a minimum, allowing any of us to purchase access or use no matter if we are a pro or basic user. This is a great and exciting function that I look forward to using!!

I really need to know what “nun coasters” are. ![]()

Coasters with picture of Nun’s…

Good to hear you are making advancements. Maybe this will translate into me ruining less material from the print always being off a quarter inch or so.

I think this is awesome and useful. I sincerely hope it will be rolled out to all. A new product at some point suffers price erosion due to new competing products coming online with new abilities. When compared to the cost of building a new product, the ability to add an advanced capability like this to all users can maintain and maybe even increase the value of existing products and dramatically enhance brand loyalty. That loyalty will be essential to success when the Glowforge 2.0 is eventually revealed. Go above and beyond now and the users will flock to the new models in the future. This is my humble viewpoint.