Didn’t you do those adorable little miniatures? You should be able to do a lot of the cutwork for those without any trouble…this thing is incredibly precise.

So part of the missing software?

By the looks of things, cuts are way off from where they appear on the screen. Precision is EVERYTHING in miniatures. (1/4" off is considered “ok” by GF but that would be 3’ in my world)

I’m not sure what you mean by that… but I’m assuming you mean am I waiting for software improvements? If so, yes, that is what I’m hoping for.

I don’t want to play cheerleader or banshie on this.

On the one hand, most people are getting way-way better than 1/4" placement with properly miked out material and it only looks to get better.

On the other hand, anything less than perfect is unacceptable if not fixed. Especially for some use cases.

I know everyone says they’re working on it, but that’s because they actually are. The one I’m testing started out off by 1/4", it’s now dead accurate. But it’s a PRU that they have a lot of metrics on. Soon they’re going to include that with the new units going out, and roll it back to the currently released units, and the placement problems are going to go away.

In the meantime, there are a couple of simple work-arounds that make it easy to get very accurate results.

Did you happen to see the grains of rice I engraved? This was months ago, with a non-fully tuned PRU unit. The unit has actually gotten more accurate with placement since then.

I guess what I’m trying to say is…patience is going to help. Things are moving along.

(I know it’s tough after a two year wait - I don’t have mine yet either, and if i were to get one right now, I’d probably have to wait a little longer for the alignment I’m getting on this one.) There’s just no way for them to hurry it up any more. Not if folks want quality.

I’m with the “Um no idea why I bought it” crowd. But I know I’ll find many a use for it. You will be seeing me here for the duration.

I’m involved with quite a few forums. I love this forum. I find it to be full of generous and creative people.

I wish I had a GF. As I wait. You all keep me dreaming. This has to be the most bazaar buying experiences for me.

I don’t have my GF Pro yet, but I already find myself in category 4. I had some core thoughts about what value I would get from the GF and then all of you amazing people on the fiorum opened my eyes to so much more. Now I anticipate that I will be frustrated by not having enough time to think them all through and create them. Someday, I will retire and then…

I don’t know if you’ve gotten your machine yet. But I’ll tell ya… The variance I’m getting is so good that I take my jobs to the (near)edge of the material and it nails it every time. I’m not saying it’s 0.00" or anything. Here in the real world, it’s not (yet). And I think some people get the wrong idea about what’s actually off. Everything you cut will be perfectly precise (kerf not withstanding). If you say you want to cut a 3.76" diameter circle, that’s what you get. It’s only the placement that can be off by up to 1/4". And that’s the largest margin of error the absolute farthest you get from center. I think, for many people, it’s rare to take, say, a 1" circle, decide to put it in the lower-left corner of the bed for some reason, and need to perfectly align a design onto it. Drop it in the center and Bob’s your uncle. Plus, if one really really really wants to hit that 1" circle in the lower-left corner, there are workarounds described throughout the forums that will get you exactly that.

Hope that long-winded speech helps you (or at least somebody)! ![]()

Same here - I didn’t buy it for any one particular thing, but because I continuously have ideas that I want to try, and some of them aren’t the kind of thing you make with a 3D printer! So while I’m sure we’ll be making things for cats to climb on / through / under , I spent the weekend laser-ing keychains for e-NABLE (a non-profit that gives away 3D printed hands for people missing fingers, etc, http://www.enablingthefuture.org ). The GF made that so easy, it took just minutes to pull up the keychain template, drop in their logo, and start printing keychains for people. And next week, who knows what weird idea will pop out.

And I have to say - lasering cardboard is AWESOME! Amazon provides an infinite supply, and you can try out ideas so quickly and easily…

There are a few of us eNABLErs here - you’ve got company ![]()

I got involved as much to find some real use for my 3D printer as anything else but it’s a great group. Lasers are great because you can find an infinite number of uses for it everywhere - I get far more utility out of the lasers and CNC than I do/did from the 3D printer (that doesn’t stop me from backing new ones on Kickstarter though ![]() )

)

That’s precisely the precision I need. Imagine a very expensive sheet of specialty paper with a hundred tiny high resolution labels on it. I need everyone of them to cut out perfectly. That is not possible with the current ![]()

Workarounds are available on other laser cutters already on the market. Been there, done that. Purchased a ![]() so I wouldn’t have to do that anymore.

so I wouldn’t have to do that anymore.

That being said, the accuracy improvement you’ve seen on your PRU gives me hope that it’s possible for all.

On the contrary. It’d work perfectly. I must not be explaining myself well. I apologize.

You’re actually doing the opposite of what I was saying… You’re not working with a 1" circle. You’re working with an entire sheet. So it’d be pretty easy. You design your cuts. You lay your material. But you align to the center. Everything else is relative. If the center is on the mark, so will be the rest.

That said, when you say “tiny” can you give me some specificity there? If it’s as small as you make it seem, many will tell you to simply make a jig for it. It will work perfectly 100% of the time.

If you give me some idea of the size of these things I’ll be happy to run off something similar, if possible, so you can see it for yourself.

I’m going to be honest with you…I don’t think this is the machine you’ll want to use to cut out a sheet of hundreds of tiny labels. That’s a Print and Cut file, and this laser isn’t designed to work that way without a lot of fiddling. (There are a couple of tutorials on the workarounds in the Tips and Tricks Matrix.) Even with perfect visual alignment, there are going to be better tools for the job.

I’ve used both now, laser and digital cutter, and your best bet for the labels is a cheap digital cutter. I can highly recommend a Silhouette machine of any kind - it has a dynamite 3-point registration that will work at the tolerances you need.

If you need the laser for cutting out parts in wood and fabric, or want to engrave on them while it’s cutting them out - that part, it’s going to handle beautifully. But it isn’t designed to cut out accurately around a pre-printed object. It’s designed to engrave in relation to a cut that you tell it to make.

Hope that helps. I just don’t want to see anybody buy this thing without realizing what they’re getting.

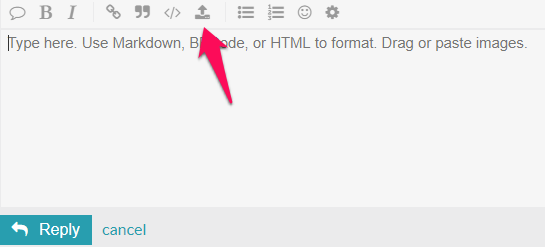

How do I post a pic in here?

Copy/paste or…

Thank you for the honest reply. That is not the only thing I wanted to do with the GF but it is one of the things that would not be possible with the current problems.

All laser cutters will do that.

Chuckle! True! It is a laser cutter after all. ![]()