If you are willing to build it yourself I can recomend Inventables.com X-carve. It is easy to build and easy to do modifications on. You must however be willing to thinker a little bit.

I am very happy with mine, but do your research in their forum on what changes you want to do. Good supportive community with great company behind it.

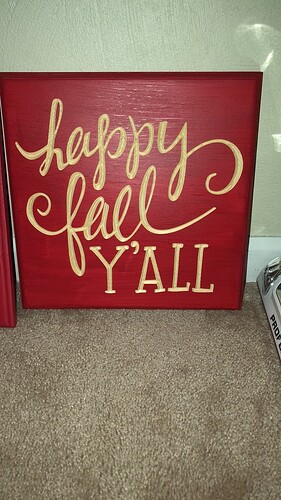

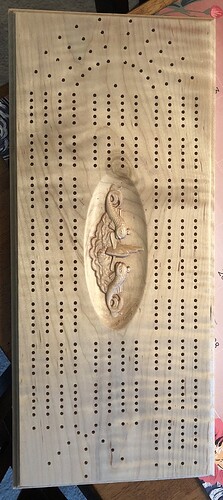

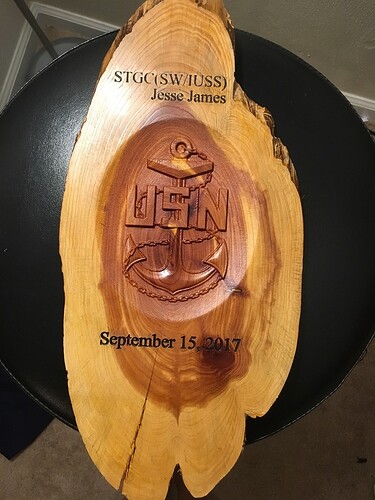

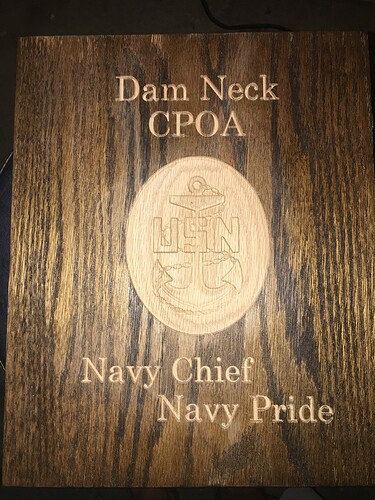

I am waiting for the Glowforge still but about 4 months ago I purchased a CNC Shark from Next Wave Automation. It runs a little more than what your range but is an amazing machine. I paid $4000 for it. It has 7” Z axis, 36 x 28” XY with 25”x25” useable. It comes with Vcarve Desktop and you can tile with that program to make engraves/cuts longer than the bed. Depending on what you intend to do with it you will need to buy specific bits for carving/engraving/cutting. Here are some pictures of things I have made on it:

Wow, I love the dolphins! One day I need to carve a set for myself.

I have made quite a few of them. After using lasers before, learning to use a CNC has a bit of a learning curve. Understanding what I can and can’t do with each bit took a little time and a lot of reading/research but didn’t take long to figure it out and still have a lot to learn. I do need both the CNC and the laser for the stuff I want to do though.

I was going to ask if you were another boat sailor but there it is in your avatar. 640 class STS a very long time ago myself.

I am STS as well. Headed to my 4th boat in a couple of months. Nothing but 688’s for me.

Beautiful work, can’t wait to see what you will do on your GF

Thanks, the Shark looks worth looking further into as well.

I would look at the benifits of the pendant. I really like the fact that I do not have to have my CPU in my shop with all the dust. It allows you to put all your toolpaths on a thumb drive and then load them via the pendant as needed. There are some out there that still require a direct connection to the CPU and as much dust as I produce in my shop I would go through a new computer fast. Just something to think about.

Look into the MPCNC. I built mine for like $300, and I built it for a 6" Z, 4’ X, 4’ Y.

You COULD go for a full 4 x 8 sheet build envelope, but you’d have to SERIOUSLY beef up the rails and support. It’s been done, but I didn’t need that size build volume.

It’s freakin’ sweet.

Thanks, this is another interesting suggestion. I have considered going the DIY route, and I do enjoy building things but it seems often the kit or DIY options seem to suffer in the reliability, ease of use and consistency depts. I do have some concerns with having to constantly fiddle with the hardware and software to keep it working properly , but on the other hand, something like this might be a good first step into the world of CNC carving and would definitely teach me a lot.

I will definitely keep you Pendant suggestion in mind. Thanks for the insight

I haven’t had to mess with mine since I built it a year ago. Works every time I fire it up.

Thanks for all the feedback, I actually learned quite a lot as a result of this thread. By some luck, or at least I hope this machine is as good of value as It appears to be, I have located a very solidly DIY built 53" x 27" x5" Z located in Canada and I will be saving a good bundle over the other options I was considering. Steep learning curve ahead…But I’m stoked to be getting to work on new ideas over the winter!