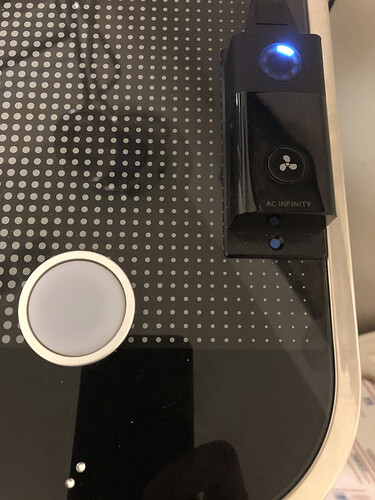

I have the Vivosun 6" and it’s insanely quiet compared to the 4". It makes me want to get an 8" and adapt it from 4" inlet to a nice breathable 8" outlet. I mounted the speed control near the GF button. It makes for a nice compliment when engraving slate a fan speed 1. PRICELESS!!

I can actually listen to music while using the machine now!