A few questions for you.

Are you doing this without the tray in? (I’m assuming yes.)

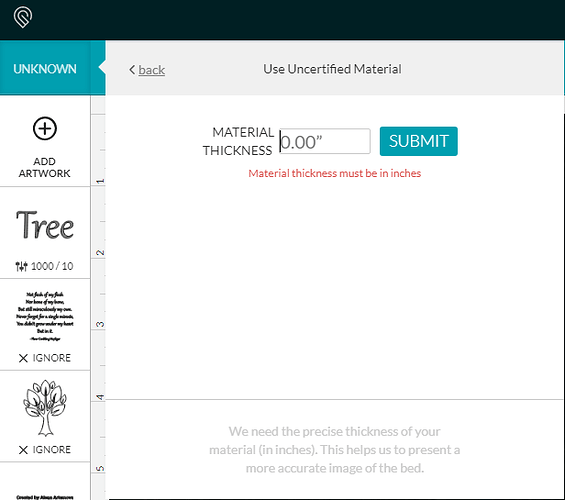

What is the height you are inputting for the material?

The way the GFUI fixes the parallax of the camera is by adjusting based on the material thickness you enter.

The problem is, the height is from the top of the tray. If you are not using the tray, you need to subtract the tray height from your thickness. My guess is your “effective thickness” will be 0.5". That should put you closer to the top surface and have less error.

@newbies_234 has made a good calculator for this.