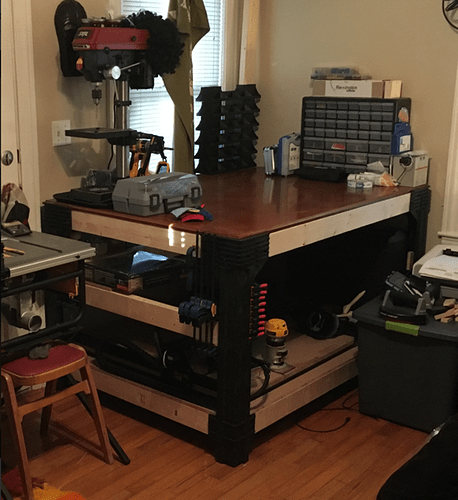

So I was considering one of these, and they are always on sale around that price, but when you get to see them in person they are really flimsy. the metal is really thin and the drawers dont feel like they could hold more than a few thumbtacks. I ended up going with a home made bench instead and couldnt be happier. It ended up costing a less too. I was also able to customize it to my liking. Ive posted it elsewhere on the forums. lemme see if i can find the post…