@chris1 did a ton of work on his installation tracking down and remediating particulates. He was measuring them down to the 2ppm level due to his sensitivities if I recall correctly. He was able to get his addressed to his satisfaction. You can probably find his stuff from a search or drop him a PM and I’m sure he’d be willing to share what he learned and how he dealt with it.

I did put a lot of effort into my ventilation setup, for a few reasons. First of all, even though don’t have any real allergies that I’m aware of, being around things like cigarette smoke, strong perfumes, etc., for a relatively short time gives me a rough, sore throat for a day or so. My Glowforge was having the same effect, and it is in the “lab”, where I keep all of my computers and electronics and maker toys, so I didn’t want to smoke myself out of my own play room. Second, it was enough that it drifted upstairs and bothered my family. And last but not least, I think particulates are a serious but relatively unknown health crisis in the making. I predict we’re going to hear a lot more about things like PM2.5 levels in the next few years.

My plan was to measure the before and after, since if you can’t measure it, it doesn’t exist. So I got myself an air quality meter. There are several on the market, and they’re not very expensive. If you really care about this stuff, you can pick one up and take the mystery out of just how much invisible death is floating in your household air. In my case, not too much, but it did spike when I operated the Glowforge. Turns out it spiked way more when I cooked pork chops… and the kitchen is located three floors upstairs from the sensor. So I know it works, anyway.

I redid the vent setup three times, first with a booster fan and then with increasingly obsessive amounts of tape. Unfortunately, despite my exuberance that it was completely solved forever, I still have some issues with smelling smoke and acrylic during a print. On the other hand, it no longer spikes my particulate meter, so there was definitely some improvement.

Thanks for the recap.

Did you try lasering the pork chops?

I am in the exact same boat you are Chris.

I may get an air quality meter to understand what is going on. I think path to outside is pretty good but because I don’t have direct control over the laser itself (the sealings, the lid, etc) I can’t be 100% sure… that’s why I inquired here.

The smoke under prints is documented by people across the board - and I wish there were a better answer for this.

GF saying post print smoke / smell isn’t “harmful” is subjective if someone has discomfort or a reaction… and also not necessarily 100% accurate.

On top of that, if someone is bothered by these issues and they want to use their laser or the room it’s in less because of the effects, nobody wins!

Instead of a totally flat crumb tray, would a crumb tray with ridges help eliminate the smoke? For example I don’t remember what the pattern is, but say it is an octagon. 6 of the sides of the octagon are the same height, while two are 1/16th shorter… so that a piece of wood sits flush with the top 6 but the bottom two allow air to flow UNDER the wood, acrylic, etc.?

It seems smoke gets trapped in this little pod under the print material, but providing better airflow in/through that pod would be helpful (?)

You could cut your own pretty quick and easy to test it out. You have material and a laser cutter.

I assume they mean that if you vent everything according to the official rules and you only use Proofgrade, they can be confident enough that you’re not producing chlorine, cyanide, or formaldehyde, and any smellz or particulates are probably no worse than you’d get by cutting with a saw. A while back I engraved a piece of MDF on my X-Carve (which has a dust boot connected to a pricey but not HEPA vacuum, and the next day I felt like I’d been gargling razor blades.

Yes, I use only proofgrade. Only using wood at the moment (freaked out about acrylic or leather proofgrades as people say they smell more)

Venting is as instructed.

I have a rabbit air purifier that I’m bringing into the room - but that’s only as a stopgap. If it’s coming out the gf - that’s the first problem. The air purifier may help- but my biggest wish it that little to nothing comes out of the GF as long as I’m doing everything right and my machine is not defective.

Interesting thought. I think this is beyond my skill level though.

The same concept applies if you cut a known thickness material and use it to shim your material up. You’re just talking about creating a gap between the material and the crumbtray. Only potential issue is material falling a bit when it’s cut through, so you’ll have to order the cuts correctly in/out.

I jumped ahead in this thread a bit when my name was mentioned and didn’t really catch the primary issue. I think there are three things that are worth considering:

- It is believed that the Glowforge exhausts more air than it intakes, such that it is operating at negative pressure, and nothing should escape from the machine itself during normal operation

- It has been widely experienced that air/smoke/smell leaks from the tiniest gaps in one’s ducting, and that it is necessary to meticulously tape every seam and joint with foil or (my favorite) butyl tape if one wants to stand a chance at eliminating escaping odors

- Some people say that with careful attention to ducting, they experience zero smoke from the machine during operation, and the only smell comes from residue after opening the door.

Now, some of those people in point 3 have very short or downhill duct runs. Mine unfortunately goes straight up. Maybe that’s why, no matter what I do, I have not been able to 100% eliminate the smoke. But I have gotten it down to a tolerable level, and my air quality monitor stays green, which says to me that whatever I’m smelling, it’s not PM2.5.

So the other point is that if you haven’t gone over all the cracks with tape, and checked them twice (at one point I could feel the air coming out in a spot where the foil had a small crease, which is why I switched to the more pliable butyl tape), there’s no point in pursuing more complicated solutions like redesigning the crumb tray. Make sure you’ve covered the basics.

Oh, and one more thing. You said that your machine doesn’t run for 10 seconds after the print finishes. That is really weird. I’d ask Support to look into that separately, if I were you.

Sorry about that but your testing makes you the forum particulate and exhaust sealing expert ![]()

Looks like there’s some interesting advice here. Since it’s beyond what we recommend here, I’m going to move the thread to Beyond the Manual.

Hi all! I have been having so much fun with my laser!

The first night my wife was in here and that evening she and I both had headaches. I realized that i could feel cold air coming in from around the vent pipe on the wall. So I went about trying the seal it as best as I could - short of using caulk.

But, I have been noticing over the last couple of days that my throat is very dry and my voice is horse. It’s been getting slowly worse. I took @chris1 's advice and bought some butyl tape. But, no doubt about it. It smells like smoke. I kinda feel like I’ve been smoking.

So far I am only cutting proofgrade stuff and some cardboard.

I believe I have the perfect ducting situation… a straight shot.

I have tried to seal the vent as much as possible… I even shoved some cloth in the gap underneath the tape.

Any advice? I’m still cutting, so it hasn’t deterred me yet. But this is a problem.

Thanks!

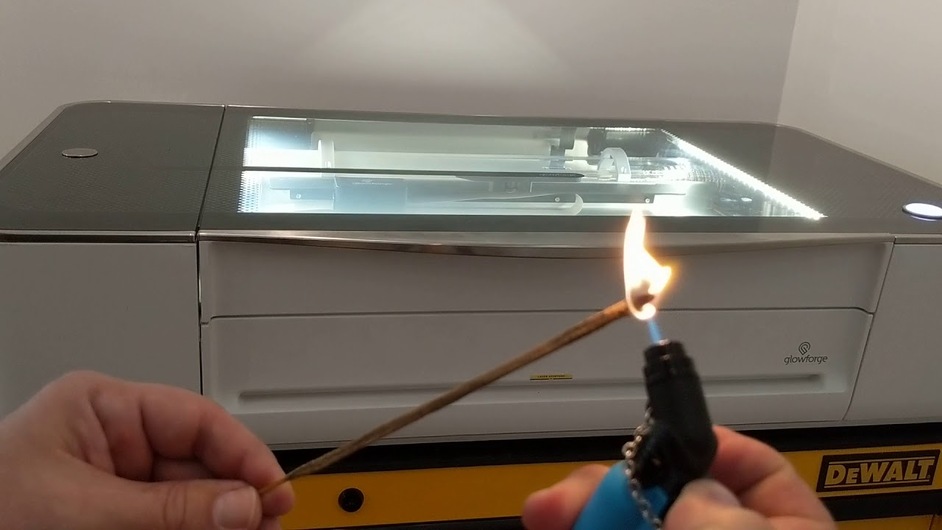

Are you sure the exhaust is coming out the other side of the wall? Does it leak around the attachment to the GF (check to see if there’s air movement using a candle flame or incense smoke stream near the connection to see if there’s air escaping)?

Also do the same smoke/candle test around the front of the GF - it should be sucking the incense in or bending the candle flame toward the GF. If it’s not, something is blocked.

I’ll second the need for many to deploy a secondary booster fan - all lasers can be pretty stinky if you’re cutting plastics or leather, so powerful ventilation is not a bad thing to have in any circumstance.

That said, here’s my quick fix for the time being:

1.) place material to be cut on the laser bed

2.) put a piece of rusty steel on the side of the bed, next to whatever I’m cutting

3.) load file to cut

4.) also load “engrave file”, just a big long rectangle

5.) set up cut as normal

6.) set up rectangle engrave on piece of steel

7.) make the engrave the last operation on a slowish speed at the lowest power

This way, I get my stinky acrylic cuts, and then I basically can buffer in however much extra fan runtime I want to clear the smell successfully. I have it set so that I’m adding about another minute of fan runtime after my cut session.

This seems to solve most of the issue, other than the offgassing of the cut acrylic… I have started putting my cut acrylic into a soapy water solution in a 5 gallon bucket, which helps to clear off the particulates and keeps the fumes/stink to a dull roar. much improved with minimal effort.

Later on though I will be installing my permanent booster fan so I can just jet-engine all the smells out the window during my entire laser time, which really seems like the best solution in any circumstance.

I took @jamesdhatch 's advice and used some incense to see if the air in the room is being sucked in. It looks like the air is going into the machine.

Also, I held the smoke near the vent hose and I did not see it being blown into the room.

Still, it is really stinky in here.

Very intersting the way the incense smoke was drawn into the GF near the top lid crack until the air assist came over then it was blown away.

Did you try at both ends of the vent hose? Where it’s attached to the GF and also where it attaches to your exit pipe out of the house?

No chance it’s being drawn back in from some other source is there? During the summer if I have the 1st floor bathroom window open, the exhaust from the GF in the basement gets pulled in upstairs because the output vent is right under the upstairs window.

“put a piece of rusty steel on the side of the bed” - I’m totally confused. why?