so on that note, in order to get an engrave to run well on the K40 requires a LOT of pre-processing. I had to sharpen the hell out of the image, crank up the contrast, etc. I made a thread about it somewhere… lemme dig it up.

Here is the thread: Preparing a Photo for Raster Engraving (NOT NECESSARY FOR GLOWFORGE)

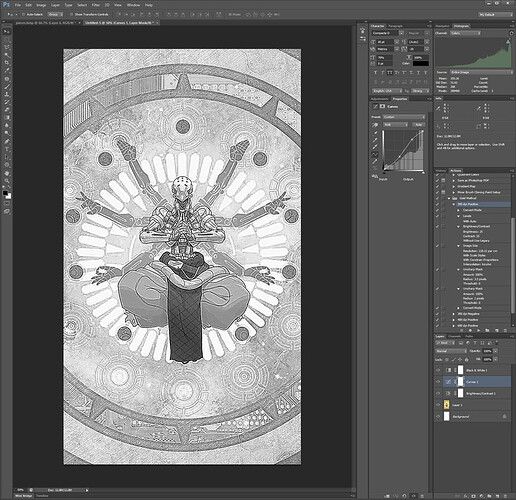

and heres what the image looked like that I had to use to keep the edges clean during the engrave. If you read through the thread youll see how much work it took to get a good engrave and why im REALLY glad I dont have to do that anymore.