I have a seklema mat And, cut a lot of paper – heavy (80-115lb) cover stock, mainly. I’ve cut at least dozens of sheets at this point. So far, I have only used one side of the mat and, have left the protective film on the other side.

I have worked with CNC cutting machines (“sign,” “vinyl,” or “craft” cutters). The mats for those degrade over time and, my expectation is similar for the seklema mat.

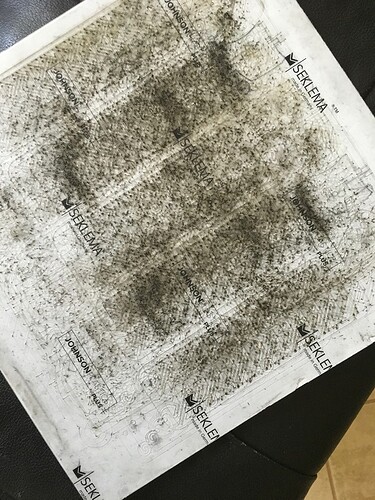

My seklema mat is looking well and properly used at this point. It feels much less sticky than it did originally:

After each session using it, I have been washing it with cold water and dish soap. The amount of tack that restores feels marginal but, it helps quite a bit.

When I put a sheet of stock down, I use a scraper (one of these but, an expired credit card works well, too) to make sure it is evenly adhered in all spots. I will make even, overlapping passes in at least two directions (e.g., lengthwise, then widthwise or, across opposite diagonals).

While bits of unremovable ash may be reducing the tackiness, this gets any given spot as adhered as possible. That reduces the chances of small pieces blowing loose and causing problems during cutting. Even with my well-worn mat, I am not (yet) having many problems with that.

I note that my mat has developed a tendency to not lay perfectly flat. So, I use strong magnets to keep it flat and in place.

EDIT: I keep the mat covered with a sheet of stiff plastic when not in use to avoid accumulation of shop dust.

This is just my anecdotal input at this point, not final recommended best practices. If someone else has other suggestions, I hope they will come forward.

Once this side of my mat stops working well enough to use, I am likely to try some more aggressive approaches to cleaning (alcohol? Orange wipes? Surface abrasion?).