I’ve sandblasted several dog show awards and I use either Greenstar vinyl (cheaper) or Oracal 651. Both work fine, but I prefer the Oracal. I found the Greenstar a bit more brittle and a pain for weeding, but admittedly I haven’t bought any for quite a while and it might have improved a bit. It works well for sandblasting that doesn’t have a lot of small detail though.

Your work is very nice!

Thanks a bunch cyn. I kinda just made my own little blasting box and learned it on the fly.

Those are very nice! Good to know the 651 works…

Looks great! Those curved surfaces turned out really well with the Oracal.

Really nice work, and thanks for the info on 651. Nice to not have to buy an additional type of material.

Nice, I really wouldn’t have expected the 651 to hold up that well. What type of media do you spray, and at what pressure? I’ve been on the fence about buying some sandblasting equipment since last year at this time, have a project that has been waiting for the glowforge that I might just need to blast instead at this point. I have a big roll of 651 that was sent to my by accident (signwarehouse fail: they let me keep the roll while they reshipped the 951 that I had ordered).

Yeah, I was flying by the seat of my pants and just using what I had on hand, but the 651 did pretty darn well for me and I’ve just stuck with using it. For the curved surfaces I just broke each element up and applied separately and then filled in around them. I did blasted awards two years in a row and for the first year I just made my own little blasting box out of a plastic tub and a sweatshirt (don’t laugh ![]() ). It actually worked OK except it was hard to see through after a bit. I made 15 awards in that little box!

). It actually worked OK except it was hard to see through after a bit. I made 15 awards in that little box!

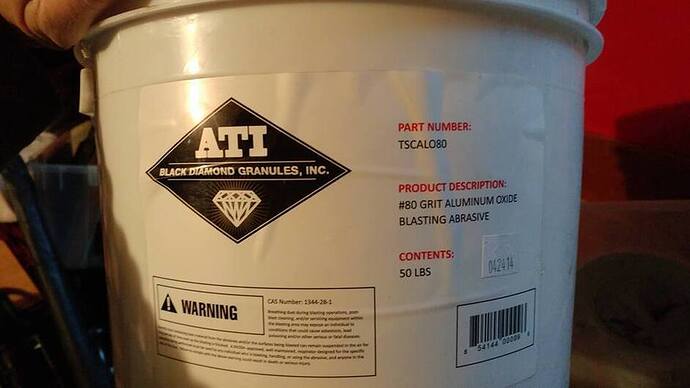

The next year I bought a Harbor Freight cabinet and gun. I *think I got the oxide from Tractor Supply and it worked great. The 80 grit made for a nice clean blast. I haven’t done it for a couple of years, but I’m thinking around 90 PSI, maybe up to 110 or so. My biggest hurdle was the compressor. The cheap Harbor Freight one blew out really quickly. Lesson learned and I bought a better model to replace it.

Looked it up and yep, bought the grit at Tractor Supply.

http://www.tractorsupply.com/tsc/product/black-diamond-aluminum-oxide-blasting-abrasive?cm_vc=-10005

Nice cabinet!

Questions, is that cabinet vented with a filter? And is that abrasive dark in color?

On mine I learned to stretch kitchen plastic wrap across the weatherstrip seal on the acrylic door, creating a gap of about 1/4" between the wrap and the acrylic. That way all I ever had to replace is the wrap that keeps the window perfect.

For being such a soft metal, aluminum oxide is hard, 9 on the Mohs scale.

Care to give us a chemistry lesson @volivaa?

The cabinet is Harbor Freight and was a really decent price. It doesn’t come with a filter, but has a port in back that I hooked my shopvac up to. The biggest downfall was no lighting. There is a hole to run a cord through though so just stuck one inside.

Here’s the oxide. Harbor Freight carried the same thing in small bottles so I tested with that first then went ahead and bought the big tub.

I don’t have the $40 white adapter thingy but this is the port for the vac. I just stuff rags in the hole becasue I’m a cheapskate lol

When you are in need of more blast media try looking at local auto body parts store. Any place that sells paint for body shops will have it and usually super cheap

What, no thats awesome! If I’m laughing, it is with you, not at you!

The $40 adapter thingy could be 3D printed for a buck or so in less than an hour. PM me if you want more info.

Thank you for the pictures!

That’s bigger than mine, which is a little bigger than a cubic foot.

Considering installing a string of LED’s in there to improve lighting as opposed to the single incandescent low watt bulb.

The shopvac is a great improvement!

80 grit? I’ve always used 240 and above grit for sand blasting ( using the air eraser). Never tried such a coarse git. Actually I did try the glass beads - creates a fine “dimpling” on the glass.

I do go back to Illustrator  The only way to adjust in Silhouette Connect I know of is to have set up your file in Illustrator with different layers as you can have different settings for each layer (pressure, dot, dash, don’t cut, etc) in Connect. Connect is also a bit glitchy sometimes so I trust Illustrator more anyway.

The only way to adjust in Silhouette Connect I know of is to have set up your file in Illustrator with different layers as you can have different settings for each layer (pressure, dot, dash, don’t cut, etc) in Connect. Connect is also a bit glitchy sometimes so I trust Illustrator more anyway.

Thanks!

Resurrecting this with the arrival of my Curio. I have lots of things in mind for it while I wait for my GF! First up for this weekend is some custom coasters for our vacation rental and playing around with pop-up cards.

I’m excited to play!

You’ll have a lot of fun with it. Just remember to post what you make