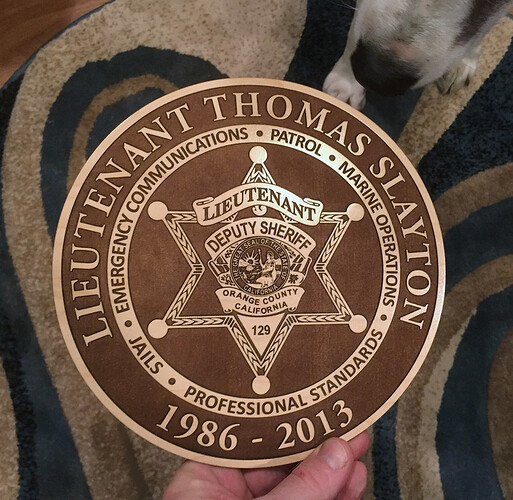

I’ve been doing a lot of wood engraving on my new GF, mostly with proofgrade maple ply. I did the one in the photo for a friend of mine, and this is the latest of several similar ones that show a certain unevenness in the engraving color. I’ve noticed on these wood engraves that once I brush off the soot and residue there are sometimes lines and areas of uneven lightness that don’t seem to be caused by wood grain or whatever natural variations you might find in wood.

My settings were 800 speed, full power, and 340 lpi, doing an engrave from a solid black and white high-res image, with no grayscale or gradients of any type. The vertical lines under the word “patrol” bother me the most, since there’s no way those are because of wood grain. So do any of you more experienced users have any idea what I might be doing wrong? I’ve been cleaning the excess residue off with a kitchen scrub brush (no liquid - even denatured alcohol was making my pieces warp). I see other engraves on this forum that look perfect, so I’m assuming this is a case of operator error. So what am I doing wrong here?