Started composing this a couple days ago, but didn’t have time to structure some final points…

I’ve been in the 3D printing realm since 2007 lobbing my STLs to a service bureau in NC. At the time, $250k-$500k was a tad much to drop on the machines.

By 2012, a handful of desktop resin printers became “affordable”. $15,000 was the price of admission for one of these machines that offered a build envelope (30mm x 40mm) to fit several rings into. Half liter of casting resin was ~$200. A resin vat replacement cost $600. Given the previous time & expense of outsourcing, it was still a no-brainer to pull the trigger on this machine.

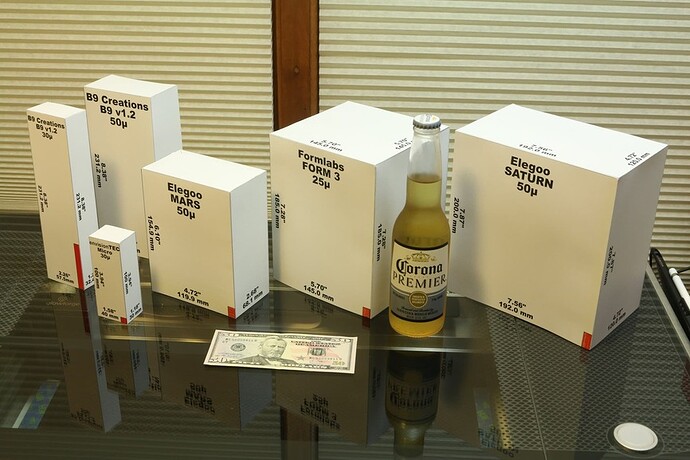

Later in that year, the B9 Creator was a $2500 kickstarter project. It’s 30 micron build envelope didn’t increase much (32mm x 57mm), but their (castable) resin was under $100 and replacement vats didn’t exceed $150. The machine offered an option to reconfigure into 50-micron printing. This decreasing of resolution tightness served to increase the build envelope to 54mm x 96mm.

This was the concurrent era where Formlabs started up. The Form1 “drew” each layer with a laser rather than a projected image the aforementioned units deployed. While I wasn’t fond of its mediocre speed and resolution, this process allowed for a “whopping” 5-inch sq build envelope. Enviable, but its other specs didn’t align with what I was after back then.

By ~2018, companies like AnyCubic offered an inexpensive resin machine in their Photon. Much of that glory got usurped when Elegoo swooped in with the Mars; a $200 resin printer with $30 resins and $50 spare metal vats. This entire daggum printer cost what a bottle of resin did in 2012! It would’ve been irresponsible NOT to try it out.

Verdict? Elegoo is legit. Overall build is impressive at it’s price point and it uses a similar stretched-FEP peel mechanism that was found in the workhorse $15000 printer from 2012. While it’s mildly annoying that Elegoo riffed out numerous variants of the Mars (Mars, Mars Pro, Mars 2, Mars 2 Pro, Mars 3) the attractive entry price has pushed ownership numbers beyond critical mass where replacement parts for all of them should remain available for a good while. The Mars lineup print at 50-micron resolution with an envelope of approx 68mm x 120mm – PLENTY of space for a handful of detailed miniatures or figurines in one go.

Moving up in size, the $500 Elegoo Saturn maintains a 50 micron resolution fine-ness while bumping its build envelope to 120mm x 192mm.

Once they’re done fulfilling their 2021 Kickstarter campaign, Elegoo may widen the pre-sell of their Jupiter printer. This monstrosity weighs in around 90lbs, could probably displace a desk, and has a build envelope of 277mm x 156mm (10 x 6 inches, 11 inches high) Likely ballparks around $1300 when out of its Kickstarter phase. Purpose of mentioning this behemoth is to put in perspective where that $1000 budget lands in the current state of 3D resin printing.

Biggest is best, rite? Only carries as much sense as buying an oven to handle a daily piece of toast. Unless there are very specific frequent needs for huge prints, the best candidate is one whose build envelope matches what you honestly need. Cost of consumable replacement parts on the larger machines mushroom exponentially. 2K LCD screen of the Mars was $30 last I checked. 4K 9" screen for the Saturn is $80. Elegoo Jupiter’s 6K 12” screen might hit $400 or more. The amount of resin required to fill the Jupiter’s vat will be a silly exercise compared to what the Mars sips.

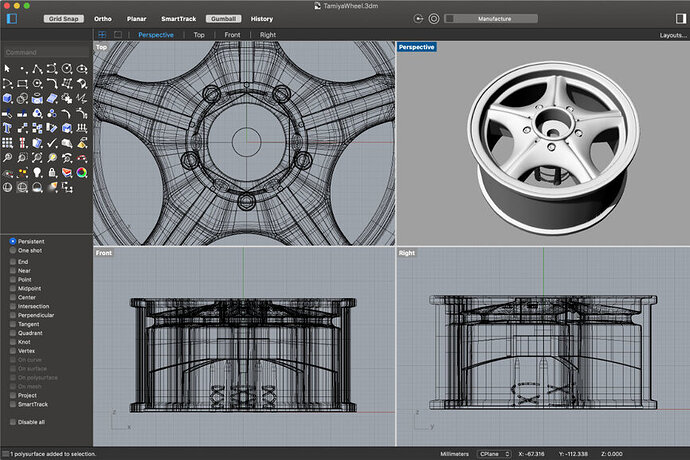

Most of the resin printers I’ve considered have started out with crafting a cardstock mock-up of its build envelope. Everything within that volume should be considered the print boundary…

This shot revealed to me that I wasn’t missing much with the Elegoo Saturn when an incoming

Form3 had a similar-enough cubic volume in their build envelopes.

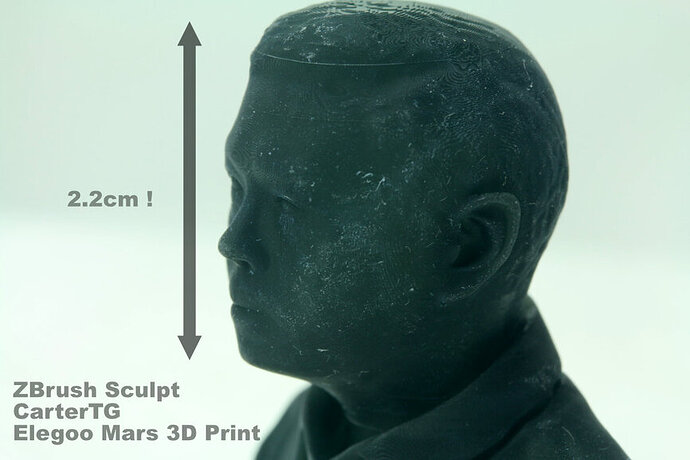

A 1:64 scale target means most human figures would be sized approximately an inch tall. Allowing for a generous quarter-inch elbow room, well over 200 characters can be arranged on an Elegoo Mars build platform for printing.

I’ll second @ekla ‘s suggestion with Nomad Sculpt. It harnesses the power of the Apple Pencil’s responsiveness/sensitivity into a highly portable sculpt-whenever-the-inspiration-strikes platform. There are plenty of beginner tutorials that’ll get you familiar with the basics.

Watch that clip on a computer screen while launching this NOMAD WEB DEMO on a Pencil-equipped-iPad and follow along.

If you discover a newfound love for sculpting and want to pursue investing in yourself, check out Vertex School’s course on sculpting & printing miniatures. The bonus bundled courses on ZBrush has applicable concepts for Nomad while the Anatomy sculpting course should lay down some solid fundamentals. I can envision a scenario where you (or someone you hire) sculpts a kitbash-ready file. Head, torso, upper arm, lower arm, etc all contained in their own layer. Whenever a character is needed, load up this master file, arrange and pose all the parts as needed, then MERGE (or copy) all layered parts into a single mesh, export as STL/OBJ and load into the 3D printer.

Last thing I want to mention in this post is that resin printing can be extremely rewarding especially the exquisiteness of detail that can magically emerge and moreso if it’s your own creation HOWEVER, the glut of all these inexpensive units on the market pretty much regardless of the brand IMO are best deployed by those who have an INTERMEDIATE skill set and knowledge of this particular process. ANY resin printer freshly unboxed will undoubtedly be dialed-in at the factory and score an easy “1” on the 1-10 difficulty scale for it’s initial prints… It’s what happens when SOMETHING, ANYTHING changes where the machine requires a re-zeroing of the platform, or a change of the FEP film, or a custom dialing-in of exposure times that the troubleshooting difficulty rating for a noob can escalate to a 6 or 7. Consequences of ignoring the what, hows, and whys of the process? This daily Reddit thread or this one of “failed print” postings will testify the point.

The question of “What’s the best resin printer” is non-sensical to me because it’s the equivalent of asking “Which faucet in that building has the best water?” ALL the sub-$3000 resin printers are capable of churning out fantastic prints and at the same time, if something goes a little sideways, they will ALL require a similar level of experience to diagnose and troubleshoot. In my 10 years in the resin printing rodeo, no 3D resin printer has been engineered to allow escaping this “intermediate experience” requirement. Some have offered a good, knowledgeable community to pull beginners up into intermediates (B9 forum) while others like envisionTEC include a bundled 2-days of hands-on certificate-completion training at their Detroit headquarters for plunking down 15 grand. Bottom line, no 3D printer will allow you to stay in a self-imposed beginner bubble so make certain you enter with the mindset of WANTING to learn everything there is to learn.