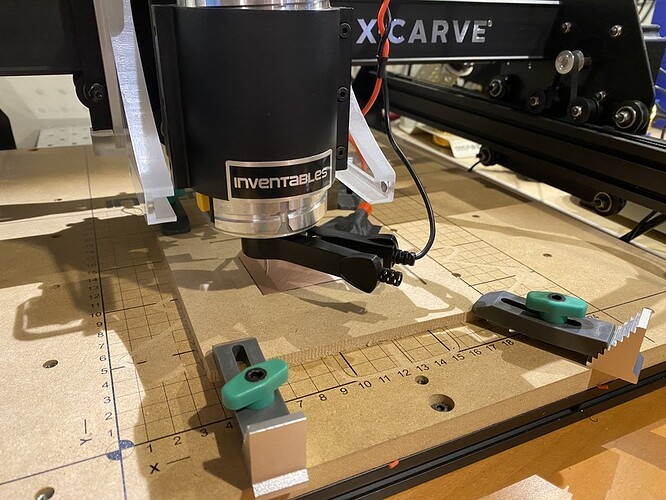

Thanks for posting this. It made me get off my butt and actually see if I could do this with my X-Carve. I expected to get close but fail, so that I could have an excuse to buy the Bantam mill.

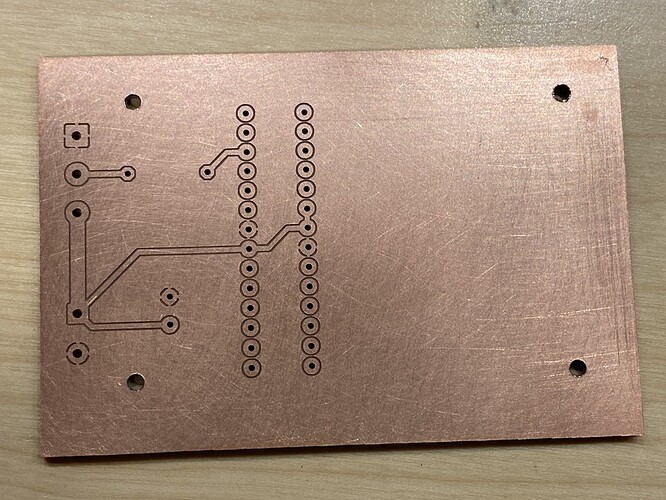

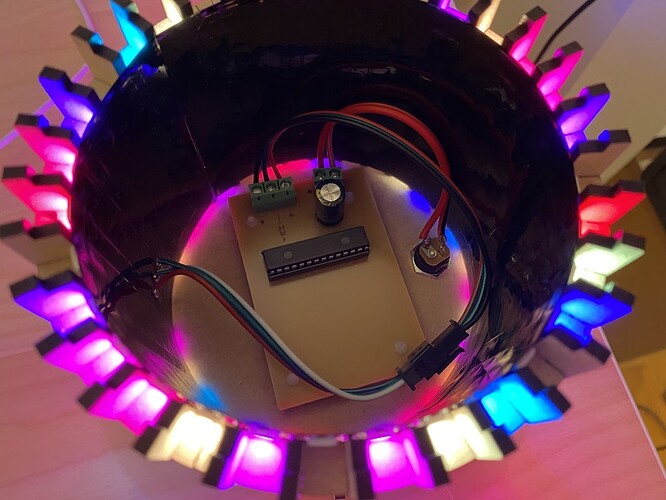

Much to my surprise, I was able to cajole rather good results out of the thing.

So I guess the bad news is there’s no new CNC mill in my future, but the good news is that I’m saving $4,000.