Any suggestions on cutting old vinyl records? I know the gases given off can be harmful but will it be OK with the filter? What about the older 78rpm records? I’ve seen some cool designs on some of these but wanted to know if the Glowforge is the tool for this job.

Don’t do it. More than harmful, also damaging to the laser. Do what I might do, laser cut a Jig out of wood or acrylic and then draw onto the LP, then dremel or other cut it by hand if you don’t happen to have a CNC mill/router. I know how awesome they look but it’s not worth the risk/damage.

ps. no the filter won’t be enough, plus most countries have environmental laws that won’t be happy.

That’s what I thought but just checking. I have all sorts of Dremel tools but they just seem so old-fashioned now that the Glowforge is here! I guess I can still do cool things with the covers!

Just consider this a reason why you also need a CNC mill, now!

I wish I had one(and the space and money…)

Me too! Building a Shapeoko 3 is next on my agenda, though, I think.

You can make wooden ones. I think there is even an application that will convert your music into a laserable file.

Jake M

have you seen the x-carve? its like a shapeoko but better! I bought one as soon as I hit 10 referrals LOL. they look pretty sweet!

I have. I don’t think the X-Carve is any better than the Shapeoko 3; I think they’re just different (the X-Carve is like an improved and upgrade Shapeoko 2 in terms of style / construction). It seems like they just went in different directions.

I have an X-Carve and have been meaning to try some album cuts. Interesting to hear that the laser isn’t the right tool for this job though. @jacktyler_co_uk - any environmental stuff aside, how does it damage the laser?

FWIW it’s worth @jrnelson, even just in terms of size, I kind of wish I’d gone with a Shapeoko 3. The 500mm X-Carve was too small for me so I got the 1000mm thinking the extra space would be handy, but the 16"x16" S3 really would have been a sweet spot for me and it would have saved me some $ too. Oh well…

You shouldn’t cut vinyl with the laser because you end up releasing chlorine, which I assume interacts with the moisture in the air to form HCl - which can rust and damage any metal or optics in the laser.

Nice to know about the sizing issue; I suspect I’d be happy with the S3 for now, but eventually want to expand it to do full sheets of ply. Would make cutting out furniture easier.

are you my evil twin?

@Mike13 Vinyl LPs are made of PVC, the C is what we care about it is chlorine. you will likely see two forms of chlorine when laser cutting or burning PVC in general. Depending on temperature and conditions you will get both Chlorine gas and vapourised HCL which is Hydrogen Chloride which makes fumes of Hydro chloric acid. All 3 are bad news the hydro chloric acid will more specifically damage your glowforge. The chlorine will also leave nasty residue on your optics of the GF. if you breathe this in or pump it outside(even through the filter) it won’t be good for whatever is outside even if it’s not too much, we don’t want you getting a nasty fine

<_<

it appears that could be a possibility haha

I love me a good answer! Thanks for the clarification!

So I have a dremmel that I never use with every attachment (I think) Its a big kit. I am liking the idea of glowforging a jig to cut various material. Would you mind ellaborating on how you do this and what attchements you use. I expect this will come in handy. Maybe start it on a new thread.

I think what @Jack was getting at is using the GlowForge to cut out a template then transfer the template onto the Vinyl record and use a dremmel to follow the the transfer.

I’m not sure what you’re getting at but I think it sounds more like a CNC with your dremmel as the spindle.

I don’t see an answer to the other part of the question. Good reason to keep topics to one subject. Anyway, 78s are made from shellac with various filler. I wonder if it’s worth pursuing. Doesn’t have the cool factor of the 33 LPs but has some value.

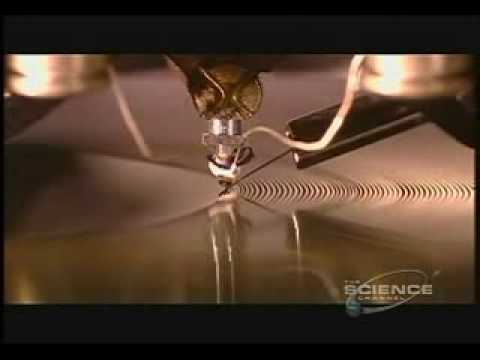

Im sure there are other fans of “How Its Made” out there.

Heres one I saw on my newsfeed this morning about how vinyl records are made:

This from library.yale.edu:

Any flat disc record, made between about 1898 and the late 1950s and playing at a speed around 78 revolutions per minute is called a “78” by collectors. The materials of which discs were made and with which they were coated were also various; shellac eventually became the commonest material. Generally 78s are made of a brittle material which uses a shellac resin (thus their other name is shellac records). During and after World War II when shellac supplies were extremely limited, some 78 rpm records were pressed in vinyl instead of shellac (wax), particularly the six-minute 12" 78 rpm records produced by V-Disc for distribution to US troops in World War II.

So be extra careful if you are going to experiment with 78s from the WWII era, and be aware that there may be other filler materials in any 78.